How thick should drywall be?

Plasterboard has established itself as a durable and reliable material used for finishing various surfaces. They can not only decorate the interior, but also make a partition, thereby turning one room into two. The indisputable advantage of this material is a large selection of sizes and designs, which allows you to choose drywall for finishing different rooms.

Pros and cons of plasterboard wall decoration

Before choosing a material for decoration, you need to know about all its advantages and disadvantages. Knowing all these nuances, you will prevent all possible unpleasant surprises during repairs and future operation.

Drywall has many positive properties.

- Thermal insulation. Plasterboard walls allow you to save on heating, especially if they are additionally insulated with foam or mineral wool.

- Flexibility. You can make absolutely any figures from this material, allowing you to create a truly original interior. You can often find beautiful arches instead of doors in apartments. You can also make niches from drywall and install built-in lamps in them.

- Fire resistance. If a fire suddenly starts, only the top cardboard layer will catch fire. In the catalogs of hardware stores there are special sheets that are completely resistant to fire.

- Moisture resistance. Plasterboard can be installed in the kitchen and in the bathroom: in conditions of high humidity, the material does not deform or collapse.

- It is easy to hide communications behind drywall. The space that remains after installing the plasterboard panel can be filled with unnecessary wires. But do not forget to make inspection hatches that will provide access to communications.

In addition to the advantages, like any other building material, drywall has several disadvantages. It must be borne in mind that it is fragile.

During transportation, installation or heavy loads, the sheet may crack, so you need to work with it extremely carefully.

If you plan to make a plasterboard partition, it is better to use sound-insulating material, such as mineral wool: the material itself does not absorb sounds. And, finally, drywall shelves are not able to withstand the weight, so it will not work, for example, to install a TV on them - you must first make a frame.

What determines the thickness of the sheet?

The choice of the parameters of the gypsum board sheet is very important, as it reduces the amount of material used and allows you to save money. Thickness takes a special place, because strength depends on it.

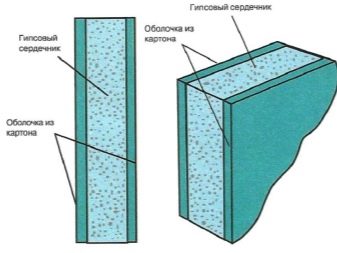

Drywall is designed for "dry" workwhen the sheet and frame are the basis of the structure. It is made by pressing a gypsum mixture between two sheets of cardboard. Special substances are added to the core, which give the sheet the required characteristics, depending on its purpose.

The greater the thickness, the higher the rigidity and strength.

The main parameter that the chosen thickness of drywall will affect in the future is, of course, strength. When choosing a material, think about what loads the future structure will be designed for. For partitions, it is important to choose the right type of plasterboard construction: single-layer, double-layer or facing. The range also includes claddings with attachment to the base wall.

Another important parameter on which the choice of sheet thickness depends is its installation. For sheets with a standard thickness, norms are established for the distance between the points of location of the frame profiles made of metal, on which the drywall is attached. If you ignore these norms and choose a material with low-quality racks, and drywall with a small thickness, then the design will turn out to be completely unreliable.

Standard sizes

Each type of drywall sheet is designed for specific work, so when choosing a material, be sure to take into account all its characteristics, especially thickness.

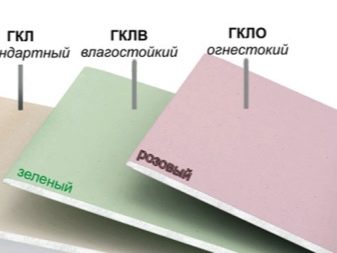

There are the following types of gypsum board.

- Wall. The thickness is 12.5 mm. There are no various additional additives in its composition. Some experts use this material for ceiling decoration.

- Ceiling. Has a thickness of 9.5 mm. It also contains no additives. Such drywall can also be used for slightly curved partitions, arched openings. The indisputable advantage of such sheets is their affordable cost.

- Moisture resistant. Maximum thickness 12.5 mm. Designed for rooms with high humidity. Hydrophobic substances are added to the core, which add strength to the material.

- Flame retardant. Thickness is 12.5-16 mm. It is used for installation in rooms with high fire safety standards. The core contains reinforcing additives. In case of fire, only cardboard will be charred, while gypsum does not burn.

- Arched. The minimum thickness is 0.6 cm. It is used for the production of all kinds of curved parts. The core contains fiberglass, due to its small thickness, the material can bend without damage. However, the cost of this drywall is too high.

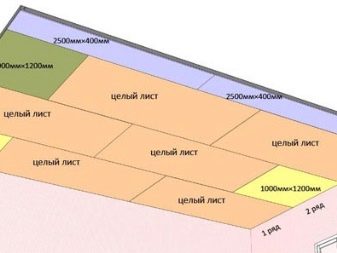

Manufacturers offer a standard length in three standard sizes: 2 m, 2.5 m, 3 m.But in catalogs you can also find sheets of 1.5 m, 2.7 m and even 4 m.Thanks to this, each customer can choose the most optimal for him option.

It is more practical to use a material with a longer length, since it will result in fewer joints on the wall. This size is convenient to use for finishing work.

As for the width, the standard size was not so long ago 1200 mm for all types of drywall. Today, the assortment of each company should include sheets with a smaller thickness - 600x1200 mm. This size greatly facilitates the process of installing the material, but it is not always convenient to use. For finishing large surfaces, drywall with such a thickness is not suitable due to the large number of joints.

Scope of application

Drywall is successfully used for leveling walls, installing partitions and much more. Also, multi-tiered curly ceilings are made from this material, which allow you to hide surface imperfections, beams, as well as all kinds of decorative elements, such as niches, columns. Plasterboard is attached to the base using a frame made of a metal profile or mounting glue.

There are three types of material depending on the area of its application.

- Arched. Has the smallest width and additional fiberglass reinforcement. It is used to install structures with complex shapes. Also, the use of such material is appropriate only in rooms protected from mechanical stress. You can make partitions, niches, multilevel ceilings and much more from arched drywall.

- Wall. It is used to decorate walls and install lightweight partitions. It is important that there is no open fire or high humidity in the room.

- Ceiling. 3 mm thinner than wall. It is used to create multi-level ceilings. There are types that withstand high humidity conditions, so such drywall can even be used in the bathroom.

Remember that drywall is fragile.Be extremely careful both during the transportation of the material and during its installation.

Advice

To prevent the renovation of the premises from "bringing" unexpected surprises, great attention should be paid to the choice of quality material. Design and production technologies do not stand still, but when choosing new models, it is better to give preference to proven brands with a good reputation.

When choosing drywall, it is imperative to take into account its strength and reliability according to the operating conditions of the material. Also pay attention to the environmental friendliness of the product.

Only well-established manufacturers guarantee that no toxic and hazardous substances are used in the production of sheets. This is confirmed by the relevant safety certificates - do not forget to ask the seller for them.

To prevent the wrong choice of drywall sheet, use the following guidelines.

- If you want to purchase a time-tested product, head to the branded stores of companies that have earned a huge number of positive reviews.

- Before buying, carefully inspect the sheets, take into account the conditions in which they are stored.

- On the surface of the material there should be no defects of any kind, namely dents and cracks. The paper should not stray from the core or curl on the back. The edges of the hem should be straight.

- Particular attention should be paid to loading the material. If you finally managed to choose the perfect drywall sheet, this does not mean at all that it will remain so when it is delivered to its destination. That is why be sure to control the loading and delivery of material.

- If you need a large number of sheets, you should not buy all at once - take a little drywall "for trial". Cut a small piece from the sheet and carefully examine it: the core should be uniform, the cut should be even, and the knife should go smoothly during cutting.

- Saving is good, but not always. Having decided to buy the cheapest option, you risk getting on a flimsy cardboard, which will be impossible to work with. Choose sheets with the best price-performance ratio.

When buying drywall, it is recommended to first calculate the required amount of material. To do this, you can use special online calculators available on the Internet.

The calculation itself is not difficult. The main thing is to correctly determine the area of the wall to be trimmed.

When decorating walls, regardless of the technology used, you must leave a 15 mm gap at the top and bottom. Subsequently, you will cover it with putty or cladding material.

Consider doorways and window frames, which may also be on the wall. If they take up little space, experts recommend not calculating them from the total area: the remaining sheets of drywall can be safely used to finish the same openings. If the openings are large or there are many of them, then there is no point in spending money on extra material.

Experts advise buying 15% more material: during work, a huge amount of unnecessary scraps will appear that cannot be used in any way. Often they buy sheets with standard dimensions - 1200 * 2500 mm, but often they choose another format - 600 * 1500 mm. The calculator calculates the required number of sheets of both formats.

You can install drywall yourself in any way: using glue or a frame. In some cases, it is necessary to make a bend from a sheet. To do this, the material must be moistened in advance, fixed to the template and allowed to dry completely. To do this, use a special roller with metal needles. When they are passed over the surface, small holes are formed on the surface through which moisture passes.

After installing the plasterboard structure, it should be cleaned of dirt and dust, and then covered with a primer.After it dries, wallpaper is either glued to the surface, or plaster is applied.

How to install a plasterboard partition, see below.

The comment was sent successfully.