Dimensions of drywall sheets

Until a few decades ago, builders had very little knowledge about drywall, and nowadays no repair is complete without this versatile material. This modern coating is widely used in renovation and finishing works. That is why it is worth getting acquainted with its main properties, dimensions and scope.

Material features

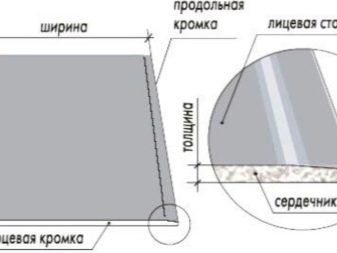

GCR is a composite material made in the form of plates. The main component is gypsum covered with cardboard. The raw material for the production of gypsum plasterboard is a gypsum core enriched with active additives that increase its density and strength. Due to this, the consumer properties of the material increase significantly, it becomes solid, but at the same time plastic.

The advantages of gypsum plasterboard are obvious:

- made of natural environmentally friendly materials;

- differs in the property to maintain certain parameters of the microclimate;

- bends well;

- has a wide scope of use;

- the acidity level of GCR corresponds to that of human skin;

- it has high soundproofing properties;

- does not emit radiation, is completely non-toxic;

- has a low weight;

- easily mounted on any surface;

- allows you to insert lighting elements inside the structure;

- has a fairly low cost;

- when processed with a special composition, it shows great flexibility and plasticity.

GKL plates are widely used for:

- forming a smooth surface;

- filling the cavities and openings formed during the work;

- installation of partitions;

- arrangement of niches;

- the formation of multi-level ceilings;

- creation of interior compositions - arches, columns, shelves.

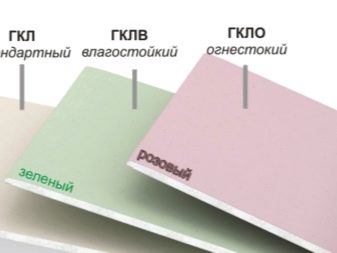

According to its technical features, drywall is divided into several varieties:

- standard;

- combustion resistant;

- moisture resistant;

- moisture and fire resistant.

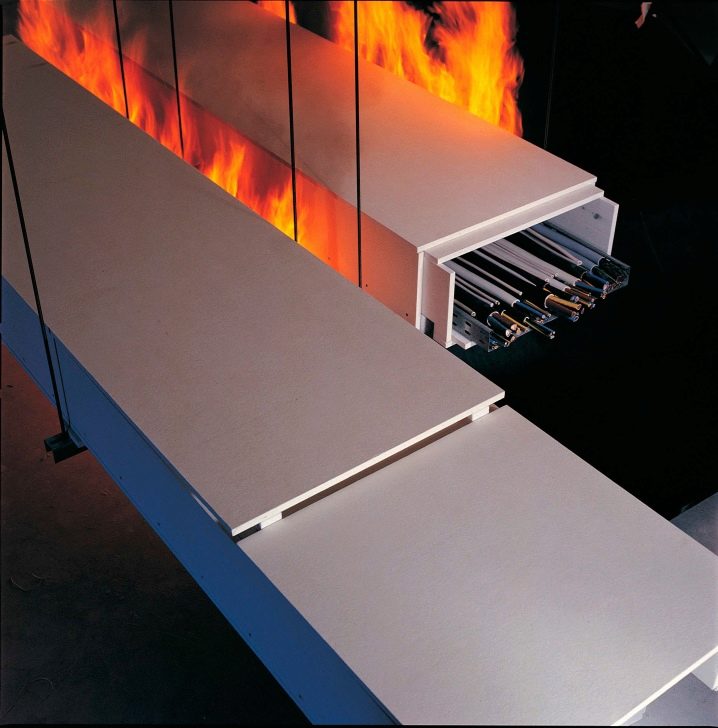

The hygroscopic model is most often used to repair shower rooms, and flammable products are widely used in the construction of communication mines, where water pipes, electrical wiring, cables for the telephone and the Internet, as well as dust removal systems are subsequently mounted.

GKL standard parameters

GKL sheets are of different types. GKL - ordinary drywall is widely used for cladding ceiling frames on walls and ceilings in rooms with a standard humidity indicator. A standard sheet of a typical gypsum board has dimensions of 2500x1200x12.5, it weighs 29 kg. This type of sheet is covered with gray cardboard and is marked in blue.

GKLV - waterproof subtype of drywall, the active component in its composition is a special hydrophobic element, and the cardboard is impregnated with a special water-repellent solution. Its dimensions correspond to the parameters of an ordinary sheet, its weight is approximately 29 kg. The cardboard is painted green and has blue markings.

GKLO is a combustion resistant model. This property is due to a special production technology - gypsum is fired under the influence of elevated temperatures and processed with a special mixture of reinforcing components. The weight of a standard sheet is 30.5 kg. The outside of the cardboard is pink and the markings are red.

GKLVO - combines hygroscopicity and fire resistance. In the production of such drywall, raw materials undergo significant processing, which increases these two parameters. Standard sheets weigh 30.6 kg, the cardboard is green and the markings are red.

Fireboard is also distinguished - a special type of gypsum board, which exhibits increased refractory properties. These plates resist burning for more than one hour and at the same time do not deteriorate their physical and technical characteristics. A sheet with dimensions of 2500x1200x12.5 cm and a weight of 31.5 kg has a thickness of approximately 20 mm. Cardboard and markings are made in a single color - red.

The parameters of the gypsum board are varied in accordance with the purpose of the material:

- Wall cladding is used for wall cladding, its thickness is 12.5 mm.

- Ceiling is used for the formation of multi-level structures, has a thickness of 9.5 mm.

- Arched is used for the manufacture of arches, columns and niches, the thickness of such a sheet is 6.5 mm.

There is no single value for the width / thickness / weight of the gypsum board, only the most common parameters can be distinguished:

- width - 600 mm or 1200 mm;

- height - 2000 and 4000 mm;

- thickness - 6.5mm, 8mm, 10mm, 12.5mm, 14mm, 15mm, 18mm, 18.5mm, 24mm 29mm.

It is these options that are widely represented in hardware stores. However, this does not mean that an exclusively standard sheet is required for work. If the interior ideas require any special parameters, then the sheets should be ordered directly from the manufacturing factory, but the whole pallet (pack) will have to be ordered. GCR parameters are determined according to SP 163.1325800.2014.

Width

As a rule, the width of the gypsum board is standardly equal to 1200 mm. Based on this, all the uprights of the frame installed for plasterboard cladding have a pitch of 400 and 600 mm. However, technologies do not stand still, and in recent years, modifications with a width of 600 mm, as well as 2500 mm 2000 mm, are on sale. Small-sized sheets are lightweight, which, of course, facilitates transportation, and even a non-professional can handle their installation.

Thickness

The thickness of the GKL sheet directly affects its scope of application. For example, for wall cladding and the creation of shelves, GKL 12.5mm is used. The thickness of the ceiling plates is less - 9 mm, but this type is quite rare on sale, therefore, the ceiling, as well as the walls, are mainly sheathed with sheets 12.5 mm thick, only the profiles are used less, and the step is 60 cm. For the manufacture of interior compositions, gypsum board with a thickness of 6 mm is used, such sheets are very plastic, they are optimal for creating arches, the formation of undulating decorative elements. However, such sheets do not withstand loads, therefore it is recommended to lay the material in 2-3 layers.

Length

Standard gypsum plasterboard has a length of 2; 2.5 and 3m. For ease of installation, individual manufacturers produce a 1.5 sheet; 2.7 and 3.6 m. For small structures, the manufacturer can cut drywall to his customers directly in production.

Length often becomes a real problem during the transportation phase, therefore, drywall with a length of more than 2.5 meters is in rather low demand, respectively, it is presented on the market in a small assortment. Too long gypsum boards can increase the unproductive consumption of material, for example, for a room with a length of 2.7 m, you should not buy a three-meter sheet. This will result in a lot of clippings that are difficult to use in any way.

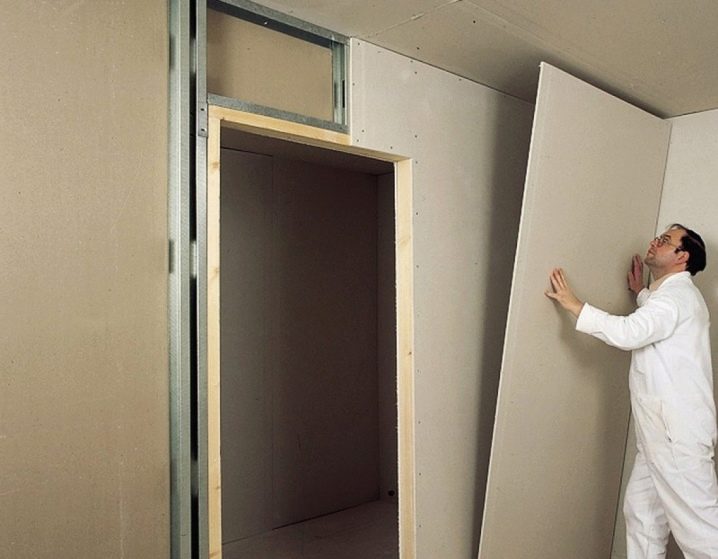

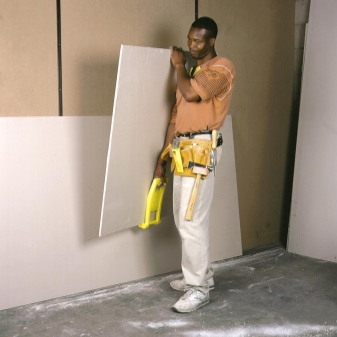

Long options are harder and more difficult to install, working with them requires assistance, since it is rather problematic to cope on your own. At the same time, long sheets allow you to avoid unnecessary joint seams, create a perfectly smooth surface. Before buying a large gypsum plasterboard, make sure that it will go to the entrance, apartment, and fit in the elevator.

The weight

When planning finishing work, you need to know exactly how much each drywall sheet weighs. This will help to correctly distribute the forces that will be required to complete all work, as well as the ability of the structure to withstand a certain load. This is very important, as it will avoid defects and collapse of the structure in the future.The standard parameters of the gypsum board are 2500x1200x125 mm, the sheet area is 3 square meters. m., such a plate weighs about 29 kg.

Conventional gypsum board, as well as gypsum plasterboard, in accordance with the standards, has a mass not exceeding 1 kg for each millimeter of sheet thickness, and the GKLO and GKLVO index per millimeter ranges from 0.8 to 1.06 kg.

1 sq. m. drywall sheet weighs:

- 5 kg - with a thickness of 6.5 mm;

- 7.5 kg - at 9.5 mm;

- 9.5 kg - with gypsum board 12.5 mm.

It is very important to correctly calculate the load per 1 square meter of coverage before starting work. If you plan to fix something heavy on it, for example, a wall is installed under water heaters, then give preference to completely deaf plates, they can cope with a weight of up to 150 kg / m2.

What does size affect?

Sizing the drywall sheet is extremely important as it reduces the amount of material used and overall repair costs. Among the most important parameters, thickness occupies a special place, because the strength of the gypsum board and, accordingly, the strength and capabilities of the structure itself largely depend on it. The thickness of the sheet should be selected based on the type of work planned. Standard gypsum board for partitions has a thickness of 12.5 mm, it can withstand 50 kg of weight per square meter of sheet without stress, however, in this case, a prerequisite is the use of fasteners for drywall, and the load should not be of a shock type. Such sheets are used to form walls and decorative partitions.

If you need to mount a single large load on the wall, for example, hang an air conditioner, then in this case, you can also use standard sheets of 12.5 mm. But at the place of installation of the cargo, additional strengthening of the crate is required.

If you plan to fix several shelves or wall cabinets, for example, kitchen or corner decor products, then it is advisable to give preference to models with a greater thickness based on the following data:

- A 14 mm drywall sheet can withstand a load of 65 kg / sq. m.

- A 16 mm plate will cope with a weight of 75 kg per 1 square meter.

- Thickness 18-20 mm is used for loads up to 90 kg / sq. m.

- A sheet of 24 mm takes 110 kg / sq. m.

If there are no thick sheets on sale, you can lay the standard gypsum board in several rows with an overlap. This may be simpler and more economical given the low availability of thick sheets on the market.

It is also important to take into account the peculiarities of the premises in which the repair work is being carried out. If this is an apartment or a private house, then it is quite possible to do with thin sheets, since the owners of the premises treat it carefully and are unlikely to purposefully inflict blows and mechanical damage. If we are talking about industrial facilities or warehouses, then the strength of the structure comes to the fore from the point of view of safety, therefore, sheathing with sheets with a thickness of 14 mm and more is mandatory here.

For the formation of interior structures, special sheets of plasterboard with a thickness of 6 mm are used. They are distinguished by their plasticity, bend well, therefore they are often used for mounting undulating decorative elements. But for the installation of arches, such a thickness is not suitable, since it will not cope with the load. Preference should be given to denser sheets or to lay thin gypsum board in several layers.

If the owner of the premises plans to hang pictures on the walls, then it is worth purchasing a sheet with a thickness of 10 mm. To mount a plasma TV, it is better to stop at the thickest sheet. Otherwise, the structure may collapse and the TV set to crash. If the wall will not be subjected to load, then in this situation it is enough to limit yourself to a gypsum board of 8 mm.

Similarly, drywall is selected for leveling the ceiling and creating multi-level coatings. You need to know exactly what will be recorded in it, and what load will be required per square meter of area.Experts recommend taking thin sheets with a thickness of 9.5 as a base point, they are lightweight, so they do not overload the floors. Such material easily withstands built-in lamps located at a standard distance of 60 cm from each other.

For conceptual multi-level ceilings, you should stop at a thinner gypsum board with a thickness of 6 mm, since a frame of this shape is not so strong, and the pressure on it is higher, therefore, you need to reduce the pressure on the floors to the maximum. In addition, thin gypsum boards are easier to install and do not require a lot of time.

Tips and tricks for use

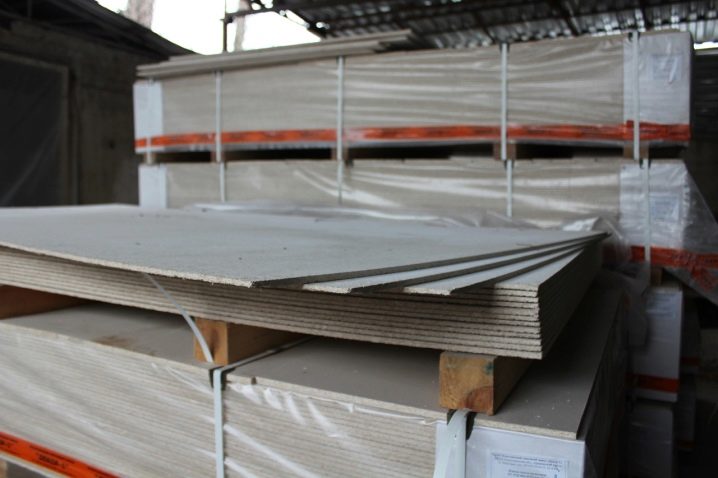

Before purchasing a drywall sheet in a hardware store, you should make sure of its proper quality. Pay special attention to the storage conditions, as many sellers store the material outdoors without any covering to protect it from adverse weather conditions, or in warehouses with high humidity levels. The constant exposure to moisture and temperature changes causes a deterioration in the technical and physical parameters of the material, which worsens its operational characteristics and in the future leads to the appearance of defects and the collapse of structures.

Keep in mind that the technical conditions strictly prohibit the installation of pallets with gypsum boards on top of each other. The increased load causes cracks, chips and deformation in the gypsum core.

It is not allowed to drag drywall sheets along the ground or uneven surfaces. This can damage the top layer of the cardboard and reduce the strength and durability of the material. It is the violation of these conditions that causes a large number of defective products in warehouses, and the buyer, especially when faced with the acquisition of gypsum board for the first time, may not even notice the damage at the time of purchase.

A few recommendations:

- Purchase products only in large hardware stores with a good reputation and high traffic and fast turnover. There should be no stale goods.

- Try to visit the warehouse and get acquainted with the storage conditions for GCR. If you feel that the humidity in the room is increased, you should refuse to buy in this place.

- When loading and delivering slabs, inspect each sheet for chips, cracks, dents.

- Be sure to monitor the actions of the movers, this will serve as a guarantee of protection against damage to the goods.

- If you plan to buy a large batch of gypsum plasterboard, then first take one sheet "for a test" - cut it with a knife and assess the degree of its uniformity

In order to avoid the unpleasant consequences of purchasing a low-quality gypsum board, give preference to products from trusted manufacturers.

- Gyproc - one of the world's leading manufacturers of plasterboard and gypsum-based building mixtures. The company has 65 factories and 75 quarries located around the world. The company makes high demands on the quality of products, tirelessly cares about improving the consumer characteristics of the gypsum board. The main advantage of this brand of drywall is its low weight - the company specializes in the production of lightweight sheets, which are 20% lighter than their counterparts.

- Knauf- the undisputed leader in the gypsum board and building mixtures market, the most popular brand of all those on the market today. The company produces sheets with a thickness of 9.5 mm, 12.5 mm and 6.5 mm., The assortment includes 4 types of sheets: ordinary, moisture-resistant, fire-resistant and moisture-fire resistant. The greatest demand among consumers is the ordinary sheet, which is officially accepted throughout the world as the GCR standard. The advantages of Knauf products are obvious: the products are lightweight, easy to process, easy to bend, polished and easy to cut.

- Volma - a domestic manufacturer of gypsum plasterboards, the products of this brand have received wide recognition from the Russian consumer.The advantages of GKL from Volma include: ease of installation, bending strength, the presence of an edge to prevent crumbling of the product. Drywall of this brand is resistant to wear, it is made of natural environmentally friendly materials and has an affordable price.

At the same time, consumers also note a number of material shortcomings - the sheets are quite heavy, there are no marking lines, and the layers themselves often have a wavy surface.

- LaFarge Is a well-known manufacturer that has been persistently occupying one of the leading positions in its segment of the finishing materials market for several decades. A distinctive feature of the company is the release of products with a semicircular bevel and edges processed with cardboard from all 4 sides. This technology allows the sheet to be used to create the ideal coating geometry. GKL LaFarge is characterized by lightness, strength, wear resistance, and also exhibits excellent sound and heat insulation characteristics. Separately, the company has established the production of bending sheets, which are distinguished by increased plasticity and are used to create arches and arched interior compositions.

At the same time, the choice of sheet sizes for this brand is quite small. As a rule, these are standard parameters - 1200x2500 or 1200x3000.

- Magma Is another Russian brand. The products of this concern have good performance parameters. It has a low weight, is well cut, and its strength is not inferior to the products of more famous brands.

How to choose drywall, see the video below.

The comment was sent successfully.