Fasteners for drywall: types and their features

Drywall is one of the most popular building materials. It is used to level wall surfaces, as well as to form partitions and other plasterboard systems. One of its disadvantages is fragility. Therefore, you have to use special fasteners that are designed to work with such products. The correct choice of fasteners will allow you to obtain a reliable and durable structure that can withstand significant loads.

Peculiarities

The technical characteristics of drywall differ from the parameters of other materials. This is due to the fact that the product consists of free-flowing gypsum, which is held by external paper sheets. Therefore, work with such a product should be especially careful and attentive. Today, to solve these problems, various fasteners and screwdrivers are used. Outwardly, these products do not differ from standard self-tapping screws for wood or metal and consist of several main parts.

Dowel

This element is optional, it is used when you need to create a strong bond between fasteners and drywall. Outwardly, such a product can have various shapes. It is adjusted to the material in which the screw will be located. Almost always they are used when you need to fix the GKL sheet to the wall.

Self-tapping screws

These products are made of metal or plastic. The shape of such hardware can be different. This is due to the fact that each of these screws must withstand different loads. In most cases, they are used in tandem with a certain type of dowel.

Views

Technically, drywall fasteners are adapted in such a way as to obtain a system that distributes the load as evenly as possible, and is also unable to destroy the product under high loads. Hardware for working with drywall has several technical characteristics. But in most cases, they use classic screws that fasten wood or metal. Conventionally, such systems can be divided into screws and dowels. They are independent elements, but are often combined to create a strong bond. You can fix the drywall sheet or work with it using several types of self-tapping screws.

Tn

This class of self-tapping screws is the most common. Such products are common fasteners that are used to work with wood or metal. They differ only in thread pitch and color. In most cases, the systems are supplemented with classic plastic dowels. It is recommended to use them in cases where a drywall sheet is fixed to a wooden or concrete base. In most cases, this involves wall or ceiling cladding.

Lb

These products are short in length. In most cases, such fasteners are used to fasten the metal profile from which the entire plasterboard system is formed. A distinctive feature of the product is the presence of a kind of drill at the end of the self-tapping screw. Therefore, it is not necessary to drill holes for them in the metal, since they themselves destroy this material well.

Ln

Self-tapping screws of this class are used to fasten metal parts from which a frame is formed.They are small in size, the tip of these products is sharp. Therefore, experts recommend stitching a metal profile with a sheet thickness of no more than 1.2 mm with the help of screwdrivers. Otherwise, these products will not be effective.

As for the dowels, they also come in several types.

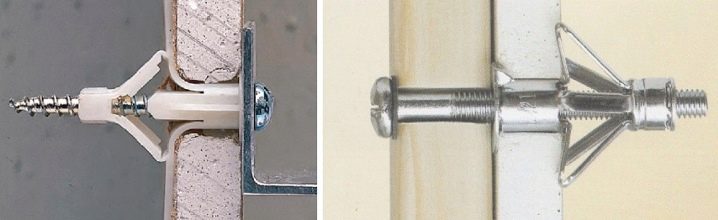

Butterfly

This fastener is used to fix lightweight products directly to plasterboard surfaces (e.g. lamps, paintings). Butterflies are made from special types of polypropylene. The technical dimensions of the dowel may vary. A feature of this product is the presence of opening elements. When screwing in the self-tapping screw, the dowel is compressed, forming an additional plane.

Driva

A dowel of this kind resembles a self-tapping screw, since there are self-tapping elements on its outer surface. This allows you to significantly speed up the installation of such structures. They are made from plastic and metal. Use this dowel to fix the drywall to the base.

Molly

The principle of operation of this dowel is similar to the butterfly variety. A screw-in screw forces the frame to compress, providing additional support. A distinctive feature of such fasteners is the fact that they are made of metal. Therefore, the molly is able to withstand quite high loads.

Dowel-nails

This type of retainer is the most common. This is a classic dowel, which is driven into a previously drilled hole to fix it. The presence of special spreaders does not allow it to slip out of the hole. To obtain a secure fit, the hole diameter must be smaller than the corresponding anchor size. Otherwise, the structure will easily come out of the groove.

Chandeliers and other similar suspension systems are usually attached to the main ceiling. If you need to fix a not too heavy lamp, use special anchors. They are threaded and complemented with various types of dowels. Technically, they can be considered a kind of self-tapping screws. Often, when installing plasterboard systems, metal auxiliary structures (for example, a sliding corner) are used. They are in a way also fasteners, but to fix them to drywall, the previously described types of hardware are almost always used.

Which ones to choose?

The type of fastener is one of the main factors affecting the reliability and quality of drywall fastening. Therefore, special attention should be paid to their selection.

When buying self-tapping screws, it is advisable to take into account a few simple rules.

- Give preference to countersunk self-tapping screws. This will allow you to easily drown them into the drywall structure. It is undesirable to use hardware for such work, which have a hemispherical head.

- The self-tapping screw must be suitable for the type of base. For example, in a log house, wood fasteners are used that will easily fit into the tree and secure the sheet. A similar algorithm can be used for timber frames that form when cladding ceilings or walls.

- The length of the screw is selected individually for a particular situation. It is important that it goes inside the frame by at least 2-3 cm. This is especially true for self-tapping screws, which are not supplemented with dowels and are the main fixing element.

- Material matters. Almost all self-tapping screws are made of steel, but the structure of the metal may differ. The cheapest are black hardened screws. They are excellent load-bearing, but can rust over time. These changes can affect the decorative finish.

The choice of dowels for plasterboard structures is an important step and involves the assessment of several parameters.

Appointment

Today, dowels can be used to attach drywall to the base or fix other products on top of this material.If you need to attach a molding or skirting board in the kitchen, then a butterfly or a driva might be the solution. The molly dowel does an excellent job with fixing shelves or plumbing.

Fastening technology

It is not difficult to screw in the dowel-drive. If you need to use other types of structures, you should understand that they need additional space. This is due to the fact that when the butterfly opens, the support systems shift. Therefore, if a drywall sheet is attached tightly to the main wall, it is technically unrealistic to use such fasteners. The solution to this problem is the usual dowel-nails and the correct size of the self-tapping screw.

Carrying capacity

Almost all varieties are used for fastening structures on top of drywall. Fixation of heavy products (for example, a massive chandelier, shelf, cabinet) is carried out only with the help of special anchors or molly dowels. These systems are capable of supporting a weight of up to 50 kg. Driva has proven itself well when fixing structures weighing up to 30 kg. The simplest and most unreliable are butterflies, with which you can hang structures weighing up to 11 kg.

How to calculate the expense?

The number of fasteners affects the reliability of fixing a plasterboard ceiling or partition. Therefore, it is important to calculate all the components before starting work in order to pre-purchase them. There is no universal formula for calculating screws or dowels. The last elements are not used without hardware. Having calculated the number of self-tapping screws, you can also find out the volume of auxiliary products.

To correctly calculate the volume of hardware, you should be guided by several rules:

- Consider the fastening pitch between the screws. The optimal distance is 35 cm. Please note that end fasteners cannot be fixed close to the end of the sheet. It is advisable to leave a gap of at least 1 cm around the entire perimeter.

- If you are installing a two-level ceiling or a structure of several layers, then on the first layer the self-tapping screws are fixed at a distance of 60 cm from each other. On the top sheet, hardware is placed in increments of 35 cm.

It is important to correctly form the crate, which often acts as a frame for attaching drywall. If the dimensions are not a multiple of the previously indicated values, you can slightly reduce the distance between the elements in order to obtain the desired fixation quality.

Advice

Working with drywall is optimally simple, but it requires observance of some nuances. This is especially true for hardware.

To get a high-quality and durable design, you should follow the basic rules:

- During installation, fasteners should only be placed at right angles to the base. This applies to screws and dowels. If the last products are incorrectly mounted, it will not work to screw the hardware into such a system.

- If you screwed the self-tapping screw at an angle, be sure to remove it and install it correctly. Experts do not recommend placing a self-tapping screw in the same hole. The best way would be to step back 5 cm from it.

- All fasteners must be completely hidden deep into the drywall sheet. At the same time, they should not be greatly deepened, since the material can be destroyed.

- When installing sheets, ensure that there are no foreign objects between them and the frame. Otherwise, they can cause deformation of the structure or the appearance of cracks.

Fasteners for drywall is the main element on which the service life of this material depends. For such work, use only unique and high-quality hardware of proven brands that have proven themselves in the market. Do not forget that the work must be done very carefully so as not to damage the drywall.

What fasteners to use when working with drywall is described in detail in the video.

The comment was sent successfully.