The choice of accessories for drywall

Plasterboard is a versatile finishing material, used for finishing and creating a variety of architectural structures, as additional sound insulation. But for its installation, you need a whole arsenal of special components, diverse in their purpose. To correctly select all the necessary parts, you need to have an idea of their main functions and features.

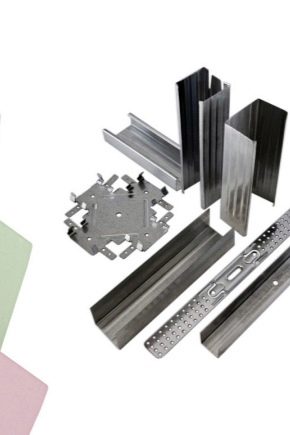

Details required for the installation of gypsum board

If the proposed work is not limited to simple cladding with the help of plasterboard sheets, then you will need to create a frame to which the material will be attached, because it has significant weight. Such a crate is mounted using different-sized profiles, connected by fasteners.

Main components for gypsum board:

- plasterboard profiles;

- connecting metal elements;

- fasteners.

It should be immediately noted that all components must be strong and of decent quality in order to ensure the durability and reliability of the structure. At the same time, it is worth paying attention to the weight of the products so as not to create unnecessary stress.

A strong frame is the basis for further work, therefore professional craftsmen recommend not to save on the thickness of the rack-mount profiles.

As a rule, the components have standard factory dimensions, but in some cases it is possible to purchase under an individual order.

Drywall profiles

To work with drywall, in most cases, galvanized steel metal profiles are used, which differ in their functional load. They are cold rolled and equipped with longitudinal stiffeners for increased strength. The standard profile length is 3000 mm, although in practice parts of other sizes are also produced - from 2700 to 6000 mm.

Products are classified into several types:

- The rack profile is made in the form of a channel with a U-shaped section and has curved shelves. This is the main element of the frame - it is used as a vertical post. Special grooves on its back ensure the connection of drywall sheets. The grooves on the sides are needed for the screws. The usual depth is 50 mm with a width of 50 to 100 mm.

- The guide profile has a U-shape and serves as the basis for guiding the rack product. It has the same width as it has, but differs in height - 40 mm. Elements are mounted in pairs.

- Ceiling details are used for cladding of single-level and multi-level ceilings. In their shape, they are similar to rack-mount components, have the same stiffening ribs and curved shelves. In fact, this material is often used for plasterboard wall cladding. They are 60 mm wide and 27 mm deep.

- Paired with a ceiling, a ceiling guide profile with a width of 27 mm and a depth of 28 mm is often used.

- Corner pieces are needed to give strength to the outer and inner corners to prevent deformation.

Profiles are used for wall decoration, as well as for the construction of partitions. In the latter case, when choosing a profile, it is important to take into account the height of the structure. The larger it is, the wider and thicker the metal should be. If necessary, such products can be shortened using a cutting wheel, grinder or special scissors.

Additional frame fasteners

To firmly dock the guides and rack components together, auxiliary elements are needed.

For these purposes, connecting fasteners are used, which have perpendicular directions to each other. Self-tapping screws are required to install it. The longitudinal connector is used to extend profiles. These elements are required when creating false ceilings and other structures.

A special place in the installation of gypsum board is occupied by the "crab" - it is a connecting component made of galvanized metal, which has a cruciform shape with bent legs, which allow fixing the part to the profile. Additional legs have holes for fastening with self-tapping screws. The connector can be attached to the surface and through the hanger, thanks to the auxiliary holes in the sides and in the center. Such a part is capable of withstanding a load of 20 kg or more.

"Crabs" are:

- Single-level - functionally designed to connect profiles in one plane with a large area of \ u200b \ u200bthe room, when the length of the products is clearly not enough. Most often, they are used to extend the supporting segments in the ceiling structure, located perpendicular to each other. Their thickness is no more than 0.06 mm. At high loads, there is a sense of additional fastening with self-tapping screws.

- Two-level products - fix vertical components that are at right angles at different levels. Double-sided fastening ensures the strength of the structure.

Also, a direct suspension is used to connect drywall with ceiling sheathing. It is a metal plate with special cuts and perforations. One side of the part is attached to the ceiling, the other fixes the profile at a certain height. It is able to withstand a load of up to 40 kg. Anchor suspension performs a similar function when the length of a straight element is not enough. It can withstand a maximum of 25 kg of weight per square meter. m.

Fasteners

All types of metal profiles and connecting elements require additional fastening for stability and strength.

When installing drywall sheets, the following are mainly used:

- Self-tapping screws - these parts are relevant for connecting drywall to metal surfaces. In different cases, it makes sense to use piercing or drilling products (type LB and LN). They can be replaced with a part with a press washer, which has a less massive head. If one layer of gypsum board is provided, then fastenings with a length of 25 mm are suitable, with a larger number of layers - 40 mm.

- A wedge anchor is necessary for hangers, it is the best solution when creating a ceiling cladding. These fasteners hold weight firmly and are corrosion resistant.

- The dowel-nail is intended for fastening on brick, concrete, stone bases. To perform high-quality fixation, a drill is used, after which the cartridge is inserted and manually hammered with a hammer.

When cladding walls, they usually take polymer dowels made of polypropylene or nylon; for the construction of ceilings, metal parts are used that provide increased strength.

Helpful hints

In order for the plasterboard structure to serve for a long time, some nuances must be taken into account:

- when choosing a profile, characteristics such as length and width are important, since quick and easy installation depends on this;

- thin metal parts may not support the weight of the structure, therefore, for long-term operation, an accurate calculation of the width of the products is necessary;

- you cannot purchase materials even with the slightest traces of rust, it is best to choose galvanized steel;

- for the installation of gypsum board, it is not advisable to buy construction nails, since they damage drywall;

- you should pay attention to the notch - it should be clear and pronounced;

- burrs, blunt tip of fasteners, sagging on plugs of dowels - these are defects and signs of poor-quality goods.

Knowing these features, you can avoid disappointment during the work. It does not hurt to ask about the quality certificate - this will be an additional guarantee of the quality of the components and will ensure the successful improvement of the premises.

For information on which profile to choose for drywall, see the next video.

The comment was sent successfully.