Acoustic drywall: types and characteristics

The task of acoustic drywall is sound absorption. This is an important nuance, implying an improvement in acoustics characteristics in the room itself and is not intended to isolate extraneous sounds outside the apartment. Different types of such material have their own technical characteristics.

Features of building material

Soundproof plasterboard is an innovative coating that has appeared relatively recently on the construction market. It is used for walls and partitions to create an optimal sound level.

This effect is achieved by making a special perforated coating structure, the back of which is a special non-woven fabric. Sounds are muffled inside the plasterboard holes. Acoustic gypsum plasterboard is available in any color scheme, but mostly these are classic white, gray and black tones, so the material can be selected depending on the overall color orientation of the interior.

Based on the main purpose of the product - creating an obstacle to the reflection of sound waves from the walls, such gypsum plasterboard sheets are applicable for cladding:

- rehearsal classes;

- educational and scientific audiences;

- premises for negotiations;

- musical institutions;

- cinemas and concert halls.

In apartments and private houses, such sound insulation is relevant when creating a home recording studio, if there is a home theater or professional music equipment.

The innovation solves several problems at once:

- reduces the level of boom;

- reduces any background sounds in the room;

- prevents echo from occurring.

Thanks to the soundproofing coating, low frequencies and human speech are more easily perceived. In addition, plasterboard cladding can be carried out independently with the help of simple tools and without the invitation of qualified employees.

Varieties of acoustic drywall

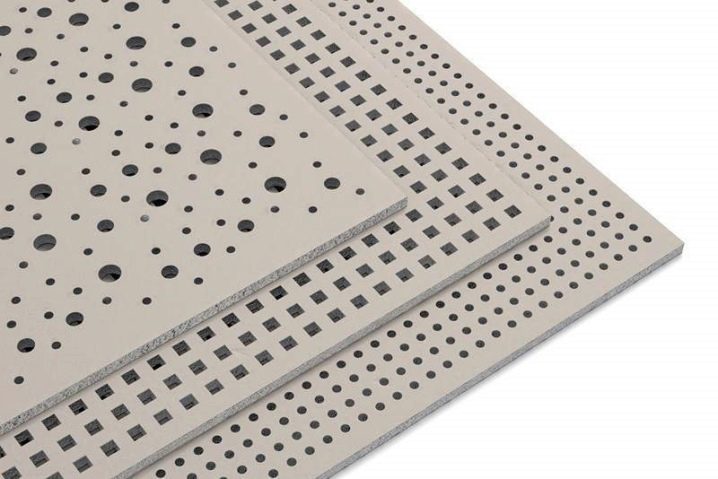

The peculiarities of gypsum plasterboards are in the shape and location of the holes, in fact, they are resonators, into which sound waves are trapped and, as a result, absorbed by the material.

It is these criteria that determine different types of GCR:

- perforation is round, and the holes reach 0.8 cm in diameter;

- square holes have sides with a length of 1.2 cm;

- chaotic, scattered notching with round holes can have different parameters - from 0.8 to 21 cm.

More often there is solid perforation or block perforation in the form of separate groups on the side surfaces of the slab.

Soundproof gypsum board models may differ in their edges. These are "FC" - sheets with folded (curly) edge and "PC" - with straight edges. An interesting detail of some sheets is the combination of different edges. So, 2PK / 2FK drywall has two curly and straight edges.

The type of perforation has a direct impact on both the quality characteristics and the appearance of the gypsum board.

Technical specifications

If we take the dimensions of ordinary drywall and soundproofing, then they are noticeably different:

- the width of the acoustic slabs varies - from 118, 8 to 120 cm;

- the length of different sheets ranges from 199.8 to 240 cm;

- the weight can also be different - from 8.8 to 9.5 kg.

- gypsum plasterboard without taking into account the canvas has a standard thickness of 12.5 mm;

- the material has a density of 650-730 kg / m3.

During technological tests, it was proved that the greatest sound absorption occurs at medium frequencies of 500-2000 Hz and has an indicator of 0.85. For all types of drywall panels, it is 0.55. In this respect, the scattered plates with round holes have the lowest results - 0.45.

It turns out that the acoustic index of drywall depends on the type of perforation. But for any size and weight of the material, the sound insulation coefficient should be 0.2 <>

Popular brands

Today, there are three brands of the highest quality and most popular products:

- Sound-absorbing plasterboard "Knauf" Is a high-quality coating for residential and public premises, created on the basis of environmentally friendly raw materials. The material is distinguished by a variety of shapes, sizes of edges, which allows you to make seamless sheathing even on curved bases.

- Soundproof sheet Gyproc AKU-line has clear advantages over similar products, since it has a refined edge. Thanks to this, the overall structure is produced without unnecessary thickening and is lightweight without overloading the surface.

- Rigiton Plates - high quality, versatile material from Denmark. The decorative acoustic product has a unique perforated design, eliminates the visibility of seams, absorbs noise as much as possible, and has optimal strength and durability. It can be painted and repaired. In addition, Rigitone Air sheets are equipped with an air purification function.

When purchasing a product, you need to have a good idea of how the installation of GKL sound-absorbing plates is carried out.

Installation of ceiling and panels

Products with acoustic properties are used for the construction of ceilings and walls.

To mount the plates, you will need the same tools as for an ordinary drywall sheet - an angle grinder, a narrow-shaped spatula, a building level, a float and a sanding mesh. And also required: a drill, tape measure, plastic tube, drywall knife, manual, rammed plunger gun

The supporting frame is made of galvanized profiles. Reinforced and combined suspension options, two-level "crabs" are also used. It is important that the end joints between the slabs are in the center of the profile. Sheets are stacked without displacement. If the structure is intended for a room with a large area, deformation cuts are made every 15 m - they are necessary to reduce the load.

An uncovered strip 1 cm wide is left along the perimeter and sheathed it with ordinary gypsum board in the form of a decorative horizontal tape. Such a frieze can also be placed on top of the sheets.

Required recommendations

Despite the sufficient simplicity of the workflow, it is necessary to follow some rules that will help to avoid poor-quality cladding, and this, in turn, will affect sound absorption:

- it should be remembered that sheets with the same edges and perforations are used for facing one surface;

- joints between panels are putty without using a serpyanka and other types of reinforcing tape;

- before work, sheets of drywall are cut off with a slight bevel so that they are better held by the solution and do not move;

- 3-4 mm must be left between the plates;

- first, the recesses from the self-cutting screws are treated with putty, and only after drying are the seams closed and engaged in grinding;

- in the process of work, it is advisable to control the location of the perforation - the holes should be at the same level;

- after fastening with self-tapping screws for strengthening, you can additionally go through the seams with putty, the excess is removed, and the screw caps are sealed with the compound.

You can paint the panels with oil paint, but it is better to do this with a water emulsion.

Do not use lime or silicone-based coloring compositions, since such solutions can negatively affect the structure of the drywall.

Positive customer reviews show that proven products from well-known manufacturers do significantly reduce "internal noise" and are distinguished by enviable durability. They also look good regardless of the style and design of the rooms.

Acoustic gypsum board is a modern sound-absorbing coating that is free of toxic substances and is safe to use.

It is easy to mount, it can be painted in the desired color with any dye composition. The seams are virtually invisible on the finished surface. If you need to sheathe the ceiling or walls with this material, then this is quite possible. Using a special tape for reinforcement - serpyanka, there is always the possibility of erecting a continuous covering without joints.

For more information on installing acoustic drywall, see the following video.

The comment was sent successfully.