Cement-sand shingles: pros and cons

The quality and durability of the structure directly depends on the choice of roofing material. The modern market offers a lot of solutions to the attention of the buyer, against which cement-sand tiles are especially popular. This article will tell you about the pros and cons of this material, as well as about the features of its production.

Features of production

Cement-sand tiles are analogous to ceramic roofing material. She also has an external resemblance to him. It is made from a mixture of quartz sand, cement, binders and water-repellent additives, as well as a coloring pigment. In production, mainly high-quality raw materials are used. Usually it is cement from 200 and above.

The production technology is somewhat different from the manufacture of a ceramic analogue. It does not provide for the firing of the bars, which reduces the cost of the final raw material. During the mixing process, sand, water and various additives are added to the cement. The components are mixed in proportions to obtain the desired characteristics of the finished cladding. To increase the strength and reliability indicators, harmful impurities are removed from the composition.

Usually, for such a composition, river sand is used, in which there can be small stone inclusions up to 2 mm in diameter. After mixing until smooth, the solution is poured into special molds. The elements are formed, pressed and dried under the conditions stipulated by the technology. The process of forming the material takes about 12 hours. During this time, the roofing raw materials acquire the required qualities.

A continuous profile is formed from the finished solution using a machine. Then the machine independently cuts it into the desired fragments. A layer of primer is then automatically applied to each of them. After the soil has dried, the material goes on sale.

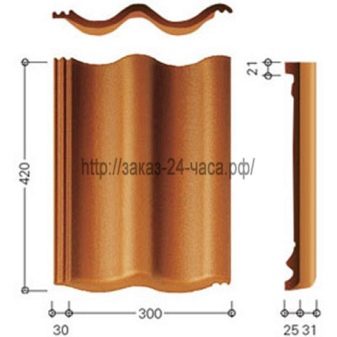

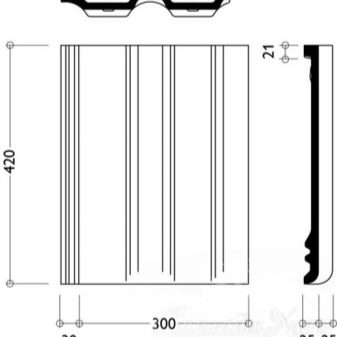

The structure of the bars can have several elements. The main lock can be single, double and triple. It is necessary to exclude roof blowing. Side locks reliably connect the bars to each other, prevent water from flowing. They can be bottom and cover.

Reinforcing ribs are needed to resist splits in the shingle material. The edges of the CPC are characterized by a rounded shape. This allows the water to drain off. The form provides for the presence of hooks for fastening to the crate. Point contact is provided between the slats and the bars.

Specifications

Consider the main parameters of cement-sand tiles based on their strengths and weaknesses. The pros and cons will allow you to give a correct assessment of the roofing material, taking into account the opinion of experts.

Let's note the main advantages of cement-sand tiles.

- It is durable. If the material is made with strict adherence to technology, it will serve for 30-50 years.

- She is characterized by resistance to external factors. It does not collapse under the influence of rain, snow, hail, does not fade under the sun.

- The material is resistant to significant mechanical stress. It is strong enough. The risk of chipping during installation is minimal. Repairs can be carried out directly at the CHC.

- It is notable for its reasonable price. Even with a large volume, the material will not "hit" the budget.

- Sand-cement tiles are frost-resistant. It can withstand low temperatures and is suitable for use in harsh regions.

- The material is variable in shape and size.The buyer has the opportunity to choose raw materials, taking into account its purpose and a certain place of the roof.

- CHR is environmentally friendly. It does not rot or deform, and also has high levels of heat and sound insulation.

- It is comfortable and easy to install. At the same time, the material is harmoniously combined with buildings made of timber or brick.

- This roofing material does not rust, has sufficient thickness and an acceptable cost. It is also flexible and fire resistant.

It is worth noting several disadvantages of cement-sand tiles.

- Despite the different purposes, the main fragments do not differ in a wide variety of shapes. Manufacturing technology does not significantly diversify the range of product models.

- CHR is heavy. It increases the load on the bearing and foundation. For this reason, the structure must be made of a particularly durable building material.

- With resistance to mechanical stress, the material does not withstand specially applied shocks. Broken parts must not be placed: this can cause a roof leak.

- CHP is a small-piece raw material. The presence of details of different functionality turns the installation process into a long laying out of the mosaic.

- The surface of the cladding is rough. This complicates the snow melting and forces you to think over the roof truss system.

Sizes and shapes

Sand-cement tiles are divided into two types of products: basic and additional. The first is used for the main roofing. The latter are used to close the joints.

According to the form, the CPC is divided into 9 types.

- Private. It has a wavy shape, it is used on straight planes for installation in the form of straight rows.

- Pediment. Side tile in the shape of the letter G. It can be left-sided, right-sided, universal. Required for roof ends.

- Half. Complements the stacking of ordinary fragments where it is necessary to close a small empty area. Eliminates the need for the master to trim raw raw materials.

- Checkpoint. A separate fragment of a narrow shape with a hole. Required for mounting support pipes on the roof.

- Footboard. Allows grates to be secured so that they can be moved safely from top to bottom for roof maintenance.

- Ventilation. A small fragment with a ledge and a masked grill. Promotes air circulation in the valley area, on the ridge or in the cornice area. Eliminates the formation of condensation.

- Supporting. It is irreplaceable in places where snow barriers are installed. Differs in particular reliability in comparison with in-line. Prevents a sharp descent of ice.

- Ridge. It is divided into 2 types: initial and final.

- End. It completes the overall look of the roof. Closes all visible joints.

The dimensions of the CPC depend on its shape. For example, the standard dimensions of the half-type version are 42 x 18 cm. The parameters of the main material are 42x33 and 41x24 cm. In the first case, 1 sq. m usually takes about 10 pieces. With parameters 41x24 per 1 sq. m of cladding will need 15 bars.

Colors and staining

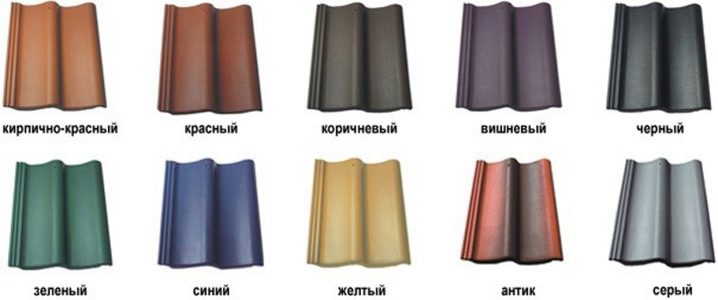

Initially, this roofing material had an unremarkable grayish color. But now, due to new technologies, it has become possible to change the shade.

This is done in two ways:

- coloring when kneading the mass;

- painting finished tiles.

In the first case, the dye is more stable. The color is stable over time. If during the installation process a chip is formed, this will not be conspicuous. A variant of the second type will have to be tinted with a special compound, which can be purchased along with the tiles.

In the modern construction market, this roofing material is presented in different shades. This is a traditional brick color, black, brown, sand, reddish shades. Gray color includes tones: dark, antique, economy. Red can be dark, red-gray, brick-red, burgundy. Unusual shades include blue and green, but each variation has a gray undertone.

Popular manufacturers and reviews

To have a better understanding of sand-cement tiles, you can take a closer look at the products of brands that are especially demanded by consumers. On the modern construction market, there are a lot of options for Russian and foreign production. The price depends on impurities and shades, as well as on the brand's reputation.

Let's mark the most popular options.

- Benders. Produces collections Carisma, Palema Brilliant, Palema Condor, Palema Exclusive. The collection includes two-wave sheets of different tones.

- Braas. Offers to the attention of buyers of the line "Frankfurt", "Yantar", Coppo Di Grecia. These are profiles with one and two waves.

- Sea Wave. Joint project of the Russian manufacturer with the Swedish Benders brand. Offers high performance oblique waveform sheets.

How to make it yourself?

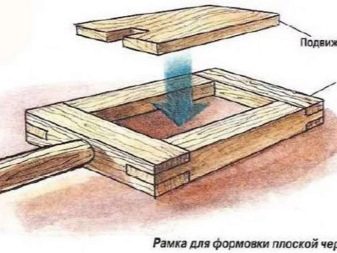

Cement-sand shingles can be made by yourself. Manufacturing will not require large costs. The technology is pretty simple. You will need quality cement of a proven brand and sifted river fine sand. In addition, you need to buy a color scheme of the desired color and prepare clean water at room temperature.

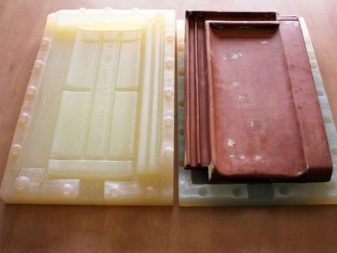

Unlike the factory technology, the process will be carried out not by vibration casting, but by piece-by-piece profile. To shape each piece, you will need to purchase a polyurethane concrete punching die. In order to properly form the sheets, a layer of concrete is applied to a clean metal sheet and left for a certain time. After that, tile elements are cut out from the raw material layer.

The device for preparing roofing material at home has a complex configuration. It includes a bowl for placing mortar, a guillotine for cutting a fragment of the desired length. A clear profile width is provided. A characteristic feature of home facing raw materials is the use of slow-setting cement for the mortar.

The way the bag is stored also affects the quality of the material. A dry composition that was stored in a damp, unventilated room is not suitable for these purposes (this reduces the astringent properties of the raw material). Sand and cement must be dry before mixing.

The proportions of the composition are as follows: in 1 hour of cement add 3 hours of sand. To this volume, 0.5 h of water is added. If the water is hard, you can first boil it and cool it. Mixing is carried out in a clean container without traces of other materials from previous construction and installation works.

Stir the mass until smooth. If a dye is used, make sure that the solution is colored evenly. When the raw materials are ready, they start molding. It is put into a mold, empirically adjusted to the amount of mass. Then the handle is pressed and pulled to the front end of the mold.

Sometimes the reciprocating motion is repeated twice. This is necessary for greater clarity of the picture. If the bar is produced with longitudinal valleys, simple downward pressure on the punch is sufficient. Moreover, its length should be equal to the length of the form itself. The punch is able to squeeze out the desired pattern. Due to this movement, the front surface of the sand-cement tile is ironed.

Installation tips

In order for the installation of the roof by means of the CPC to be of high quality and durable, you should arm yourself with some recommendations of specialists.

- The cross-section of the bar is subject to the step of the rafter system. The smaller it is, the smaller the CPC should be. The parameters of the lathing pitch should be from 31 to 34.5 cm.

- Buy only the right amount of material. You can calculate it using an online program or a specialist in a specialist store. This will minimize waste.

- The recommended overlap between the tiles can be up to 7.5 to 10.5 cm from the bottom up.

- The minimum angle of inclination when laying roofing sheets is 22 degrees.

- Do not forget to lay vapor and waterproofing before laying the roofing material, securing the free edges with panels.

- Start with the bottom row. It is he who is the main one. Align the rest on it and check the level.

- When nailing the material to the frame, use lightweight construction nails or clamps.

- Equip the last row with a ventilation duct. Use bars with gaps around the edges for this purpose.

- Finish the laying of each horizontal pediment row by installing a bar with a bent end. Make sure that the distance between the ordinary (basic) and gable tiles coincide.

- If you need to cut a block, use a sander for this purpose.

- When lifting the roofing material up, be extremely careful not to break the shingles on the ground. Raise it in portions of 6 - 7 pieces.

See below for the difference between cement-sand and ceramic tiles.

The comment was sent successfully.