All about desiccant dryers

It is very important to know everything about desiccant dryers and how they work. Air dehumidifiers can be operated thanks to cold and hot regeneration. In addition to this point, it is necessary to take into account the types of adsorbents, areas of use and the nuances of choice.

Types and principle of work

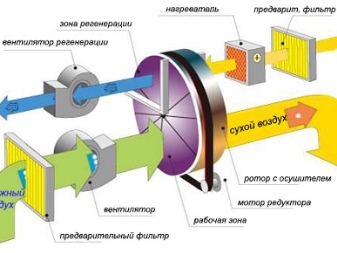

From a technical point of view, an adsorption air dryer is a very complex device. Its important component is the rotor. It looks like a large drum, intensively absorbing moisture from the air due to a special substance inside. But the air jets enter the drum itself through the inflow channel. When the filtration in the rotor assembly is complete, air masses are discharged through another channel.

It is worth noting the presence of a heating block. A special heating circuit increases the temperature, increasing the intensity of the regeneration. There is a special air duct inside that separates the unnecessary flow from the rotor. The basic scheme of action is as follows:

- air enters the inside of the rotor;

- the substance takes water from the jet;

- through a special channel, the air is carried away further;

- along the branch, part of the air after drying enters the heating unit;

- the stream heated in this way dries up the moistened adsorbent;

- then it is already thrown out.

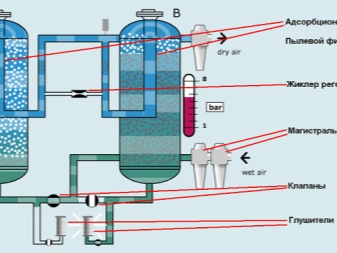

The device for cold regeneration involves blowing the pre-dried mass through an adsorber. Water collects in it and flows out of the bottom, then it is removed. The cold option is simple and cheap. But it only handles relatively small streams. The speed of the jets should be 100 cubic meters. m in 60 seconds. Hot regeneration devices can operate in an external or vacuum scenario. In the first case, the moving masses are warmed up in advance; for this purpose, external heating systems are used.

Special sensors monitor overheating. The air is under increased (in comparison with atmospheric) pressure. The costs for this hot regeneration are very high. As a consequence, the use of such a technique for small amounts of air is economically impractical. The vacuum approach also requires warming up. Therefore, a special heating circuit must be switched on. True, the pressure is inferior to normal atmospheric pressure.

The adsorbent assemblies cool down due to contact with atmospheric air. At the same time, losses of the dried stream are guaranteed to be prevented.

Varieties of adsorbents

Quite a lot of substances have the ability to absorb water from the air. But that's why choosing them correctly is critical, otherwise it will not be possible to ensure sufficient drying efficiency. Cold regeneration involves the use of a molecular sieve. It is made from aluminum oxide, which is preliminarily brought into an "active" state. This format works well in temperate latitudes; the main thing is that the outside air does not cool down to more than -40 degrees.

Hot dryers usually use solid adsorbent. Many systems use silica gel for this purpose. It is produced using saturated silicic acids mixed with alkali metals. But simple silica gel chemically breaks down on contact with dripping moisture. The use of special types of silica gel, which are specially designed for its purpose, helps to eliminate the problem. Zeolite is also actively used. This substance is created on the basis of sodium and calcium. Zeolite takes in or gives out water.Therefore, it would be more correct to call it not an adsorbent, but a humidity regulator. Zeolite activates ion exchange; this substance remains effective at temperatures from -25 degrees, and does not work in severe frost.

Applications

Adsorption dryers are used in a wide variety of applications. They are also used in domestic conditions to maintain a good microclimate in houses and apartments. But the elimination of excess moisture is advisable not only there. This type of technique is also used:

- at machine-building enterprises;

- in medical institutions;

- at food industry facilities;

- in warehouses of various types;

- in industrial refrigerating chambers;

- in museum, library and archival practice;

- for storing fertilizers and other substances requiring limited air humidity;

- in the process of transportation of bulk cargo by water transport;

- in the production of microelectronic components;

- at the enterprises of the military-industrial complex, the aerospace industry;

- when operating pipelines that carry compressed air at low ambient temperatures.

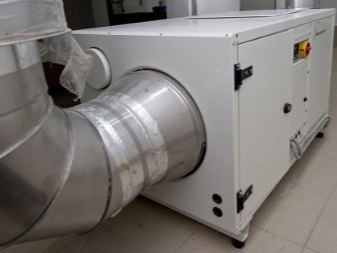

Selection rules

Adsorption systems must be carefully selected for both production and home use. But if in an apartment mistakes turn into only inconveniences, then in industry their price turns out to be significant material losses. Only a well-chosen model allows you to fulfill all the tasks. The “dehumidification class” is of key importance. Products of category 4 are able to dry compressed air only to a dew point of +3 degrees - this means that at a lower temperature, condensation will necessarily form.

This technique is only suitable for heated rooms.... If the protected circuits and objects go beyond their limits, and drainage is needed not only in the warm season, a more perfect device is needed. Category 3 structures can operate stably at temperatures down to –20 degrees. Models of the 2nd group are designed for operation in frost down to -40. Finally, Tier 1 modifications can work reliably at –70. In some cases, a "zero" class is distinguished. It is built with particularly powerful requirements in mind. The dew point in this case is set by the designers individually.

Cold regeneration is best suited for minute handling up to 35 cc. m of air. For more intensive use, only the "hot" version will do.

The comment was sent successfully.