How to avoid the most popular mistakes in the UWB device

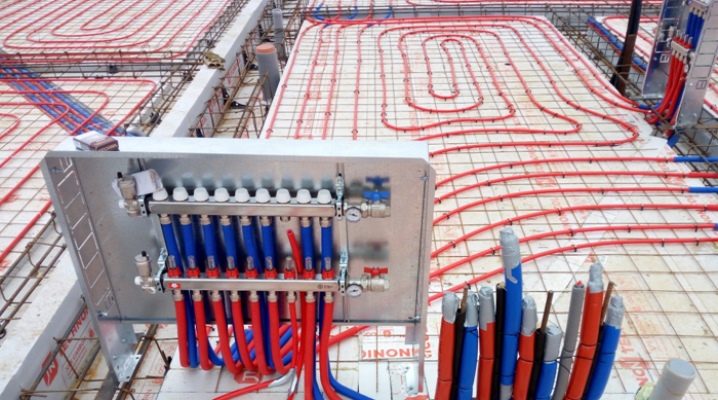

The peculiarity of the Insulated Swedish Slab (USHP) is that the foundation is arranged along the thermal insulation slabs. At the same time, a warm floor system has already been integrated into the foundation slab at the stage of its construction, and the slab itself is at the same time the foundation for the house and the finished subfloor of the first floor.

In Russia, the USHP began to be used relatively recently, and therefore some errors in the installation of the foundation can be found quite often. We will figure out how to comply with all the stages, not to miss the main thing and not add unnecessary things to the design.

In addition to the presence of a heating system and a completely ready-to-finish floor of the first floor, a distinctive feature of the technology is that the base of the slab is a high-strength insulation made of extruded polystyrene foam specially developed for this system. Floor heating in conjunction with high-quality insulation allows you to completely do without radiator heating on the first floor.

The USP has many advantages: it is erection speed, versatility (suitable for almost all types of soils), and high thermal inertia. But, perhaps, one of the main advantages of the foundation, achieved through the use of modern heat-insulating material in the structure, is its energy efficiency. Heat losses through the Insulated Swedish plate are minimal, and the ability to accumulate heat during operation allows you not to worry at all even in the event of an emergency shutdown of heating in winter.

The technology, which appeared in the United States in the 30s of the last century, only recently celebrated its 10th anniversary in Russia. Lack of experience of domestic builders sometimes causes mistakes in the construction of USP.

It all starts with the basics

The construction of the USP, as, indeed, of any other foundation, consists in the competent preparation of the foundation. In the case of the Insulated Swedish plate, it should be flat. Difficult terrain and landscape with elevation differences already serve as a contraindication for the construction of USP.

After the builders are convinced that the site fits the specified requirements, you need to start excavation. Some consider this stage insignificant and very often neglect it, laying a time bomb in their foundation. Poor foundation preparation will sooner or later affect the bearing capacity of the foundation.

Excavation of soil is carried out by 30–40 cm, after which the foundation pit is covered with gravel and sand layer by layer. At the same time, it is important to spill each layer separately with water and ram it with a vibrating plate. Is it possible not to ram and spill? Here the answer is categorical: "No". Trample underfoot, leave it under the open sky for a while, so that the sand is moistened with rainwater and compacted under its own weight - all these are solutions in which the maximum risk of losing the strength of the future slab foundation is laid. The key to the durability of the USP is a solid foundation.

Why USB drainage

Another popular mistake in the construction of the USB is the refusal to drain. Meanwhile, it performs a very important function - it removes excess water from the foundation. Otherwise, the accumulated water during freezing and thawing will either increase or decrease in volume, thereby causing the soil to move. And this, in turn, may well cause deformations of the foundation itself.It is important not to neglect the drainage system regardless of the type of soil and water table.

The construction technology of the USHP implies not only a drainage device, but also the presence of an insulated blind area around the house. Together, these measures drain water from the foundation and serve as a good prevention against the effects of frost heaving forces.

Insulation loves to count

Calculation of the thickness of the heat-insulating layer is one of the most important stages in the construction of the USP. Sometimes, out of ignorance or in an attempt to save money, builders reduce the thickness of the material. In this matter, it is important to understand that the presence of a heat-insulating layer is associated not only with heat engineering. The fact is that two-layer laying of insulation slabs allows, firstly, to reduce the thickness of the reinforced concrete slab, which means, to reduce the consumption of concrete mixture for its construction, and secondly, to form the structure of the foundation. It is with their help that a structure resembling an inverted glass is formed - with a reinforced tape around the perimeter and a reinforced plate on top.

Reducing the thermal insulation layer simply will not allow you to cope with this task. In addition, thanks to the thermal insulation plates, the entire heat flux goes into the room, and not into the ground.

Rules for choosing a heater for USP

When choosing thermal insulation for USHP, first of all, it is worth paying attention to the compressive strength indicator. Considering that the insulation will be subjected to colossal loads, it must retain its shape and properties throughout its entire service life. The material laid in the stiffeners is under pressure from the foundation itself and the supporting structures of the house.

In most cases, XPS (extruded polystyrene foam) is used for UWB insulation. It is a durable material with a low coefficient of thermal conductivity, resistant to aggressive environments, and is not afraid of water. Almost zero water absorption is fundamentally important, since the material is under load in humid conditions throughout its entire service life. Let's not forget that the insulation in the construction of the USP is laid directly on the ground, and a concrete slab is mounted on top of it, which also has a certain moisture.

But extruded polystyrene foam, depending on the scope of application, has different strength characteristics. The one that is actively used for floor insulation will not be suitable as USP thermal insulation. There are special grades designed for use under increased loads. Example –XPS CARBON ECO SP. It has a particularly high compressive strength of 400 kPa at 10% deformation and 200 kPa at 2% deformation.

Thus, the wrong choice of insulation entails several serious problems. The first of them is the loss of thermal insulation properties due to wetting, this is if a material that can absorb moisture is selected. And the second problem is related to the destruction of the insulation, if its strength is lower than that required by the technology.

Cold bridges - how to avoid when laying insulation

The heat-insulating layer during the UWB device should be as homogeneous as possible. It would seem an obvious fact. Moreover, everything is provided for this: a material with a low coefficient of thermal conductivity, installation in two layers. But here it is important to remember that XPS boards are laid with a gap in the joints, this is the way that increases the uniformity of thermal insulation. Otherwise, the joints will become, albeit small, but still bridges of cold. But when installing L-blocks, the overlap of the joints is carried out due to the L-edges.

Lock plates

It is also worth paying attention to the formation of L-blocks. In fact, the L-block is an insulated permanent formwork. Accordingly, it must be made of a material of high strength, mounted in such a way as to avoid the formation of cracks. Otherwise, when placing the concrete, the mortar will seep through the gaps formed.If the gap has nevertheless formed, then it must be eliminated, for example, using adhesive foam for extruded polystyrene foam.

L-blocks must be fastened with special corner fasteners, since these are areas experiencing additional stress. Otherwise, in the process of laying the concrete mixture, they may well lose their design position.

A little more about the nuances

The UWB device process is woven from parts. As in any construction site, each of them contributes to ensuring the durability of the entire structure. It must be remembered that laying concrete mix and working with glue-foam is possible only at positive temperatures.

There are other details to keep in mind. So, for example, when laying reinforcement, it is important to knit it on the ground, and then, when transferred to a layer of XPS, install it on special supports, known in the professional environment as "chairs". Another important nuance concerns the laying of the concrete mixture - it must be vibrated, and also carried out over the entire area of the foundation (partial laying at different times is not allowed) in order to avoid cold joints. Vibration improves the strength properties of concrete due to the fact that excess air bubbles are eliminated.

USHP is one of the most energy efficient foundations. Attention to details and rules will allow you to build a foundation in a short time, which will become a strong and energy efficient support for many years.

The comment was sent successfully.