Laying tiles on OSB boards

Laying ceramic, clinker tiles or PVC coverings on OSB boards is fraught with certain difficulties. The surface of wood chips and shavings has a pronounced relief. In addition, it is impregnated with chemicals that reduce the adhesion of the material. It is worth talking in more detail about how you can make a choice of tile glue, put ceiling tiles and tiles in this case.

Peculiarities

Laying decorative and finishing materials on OSB plates is always fraught with certain difficulties. Nevertheless when conducting frame construction, when redeveloping in a bathroom and a toilet in country houses, this material is chosen as the basis.

When finishing surfaces with ceramic tiles, porcelain stoneware and PVC tiles, there are a number of important points to keep in mind. Among the main features of the material, it is worth highlighting such characteristics.

- Low hardness and strength. The bearing capacity of OSB slabs is significantly lower than that of solid wood or concrete. At the same time, in comparison with chipboard or fiberboard, the material clearly wins in the same parameters.

- Mobility. A material that does not have a solid support bends and changes its geometric characteristics. This causes the tile or mortar holding it to crack.

- Low moisture resistance. When used in damp rooms, without additional waterproofing, the plates quickly pick up water and swell. Favorable conditions are created for the appearance of mold and mildew.

- Uneven surface. If you can immediately lay tiles on a concrete screed, the OSB board must be additionally putty.

- Low adhesion to other materials. In order for the grip to be strong, additional efforts will have to be made.

The advantages of OSB boards include fire resistance and weather resistance when used in facade decoration. In addition, the material, with the right choice, has a fairly high class of environmental safety. It can be used to create walls and partitions in living spaces.

Preparation

Before the direct laying of the tile decor is started, you need to thoroughly prepare the base. Depending on the conditions, OSB can be mounted on a frame or over an old floor, walls, ceiling. For loaded structures, it is recommended to use the thickest and most rigid slab from 15 mm. It is suitable for floor mounting.

It is possible to increase the adhesion ability of OSB boards in different ways. Among the most popular solutions are the following options.

- Additional cladding. It is possible to fix sheets of cement-bonded particleboard or drywall on OSB structures. In this case, the tiles are guaranteed to hold well.

- Installation of a metal reinforcing mesh. It allows the use of standard tile adhesives.

- The use of compounds for joining with wood. In this case, good adhesion is achieved under all conditions.

It is important to understand that in almost all cases, the installation of tiles requires additional preliminary priming of the slab. This reduces its water absorption, helps to avoid cracking and peeling of the tiles when the adhesive dries.

As part of the preparatory measures, fixing of OSB-plates to intermediate lags is also carried out.In this case, the distance between them is determined based on the thickness of the material itself. The middle range ranges from 400 to 600 mm. For floor mounting, this figure is halved.

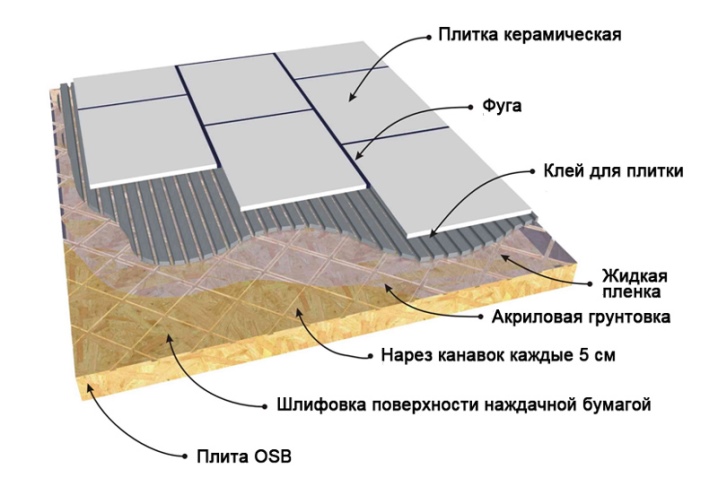

Preparation for gluing with tiles also includes grinding the material. The top glossy layer is removed with coarse sandpaper. The dust remaining after grinding is carefully collected and removed. Then the OSB-plate is covered with a polymer-based primer in 2 layers. The first is dried for about 1 hour, the second - up to a day.

As a primitive option for a primer for a slab, PVA construction glue is suitable. It is spread over the surface with a roller. It is important that there are no gaps or gaps.

How can you glue?

Special tile adhesive for fixing to wood and boards is produced by many brands. Among them is Ceresit, which has a CM17 product. Alternatively, two-component epoxy-based grouting compounds can be used. They have Litocol - the same compound can then be used to seal the seams. Suitable options include any product from the category of "liquid nails" that form a reliable adhesion to the surface of the wood-based panels.

Flexible polymer adhesives can be the optimal choice for working with tiles. They are plastic, and during the operation of the coating they compensate for the stress arising between the materials. Silicone sealants are also suitable for work, especially when it comes to decorating walls in a kitchen or bathroom. When used correctly, they will not only firmly hold the tiles, but also exclude the contact of the substrate with moisture.

Only classic cement-based compositions are categorically not suitable for working with OSB. They just don't provide enough strength. In addition, the adhesion characteristics of such mixtures are designed for other types of substrates. At best, the tiles will simply come off.

What tools are needed?

When installing tile, ceramic, clinker or vinyl tiles, the same tool sets are used. The master will need:

- rubber hammer;

- notched trowel (metal or rubber);

- level;

- square;

- paint roller;

- tile cutter for cutting material;

- spacers for tiles;

- a sponge to remove excess glue;

- a cuvette for pouring and preparing a solution.

When installing using additional elements (mesh or overhead panels), self-tapping screws and a screwdriver, nails or other fastening hardware will be required.

Tile installation instructions

It is possible to lay gypsum, vinyl, quartz or tiled tiles on the floor, walls or ceiling even if there is an OSB board in the base surface. With the right approach, even a facade structure made of porcelain stoneware can successfully hold on to it. In order to lay the tiles efficiently, you need to take into account its individual characteristics, purpose, and the intensity of the expected loads.

There are a number of general recommendations that are followed regardless of the installation method.

- Alignment. All sections of the slabs are measured according to the level. The areas where the fasteners are located are carefully filled with elastic mixtures, as are the joints between the modules.

- Padding. It is produced with a paint roller. If the type of board is OSB-3, you must first apply a solvent or alcohol to degrease the surface.

- Reinforcement. It is used for fixing floor and wall tiles on OSB-3, OSB-4 panels. The mesh is rolled out over the primed surface and attached with a construction stapler. It is important that the reinforcement layer is well tensioned. A new layer of primer is applied on top.

After that, it remains only to wait until all materials are completely dry. Then you can start gluing the tiles.

To the ceiling

Vinyl ceiling tiles are distinguished by their minimum weight, they practically do not create any load on the surface. In the case of OSB boards, this choice is optimal.It is possible to use different installation methods here. For example, if OSB forms a rough coating, logs are fixed to it, and plasterboard sheets to them, to which the tile is easily attached with standard glue.

With direct mounting, you will need to putty the surface with careful elimination of irregularities. Then the tiles are laid on the dried putty. The best choice would be spot mounting on liquid nails, which allows you to quickly form a decorative coating over the entire surface.

It is important to note that this method is only suitable for hinged lighting fixtures. Mortise and hidden ceiling lights require the use of a plasterboard base, their location, size and shape are thought out in advance.

On the floor

The most popular flooring options are tiled or ceramic tiles. In living quarters, textured modules or porcelain stoneware will be more appropriate. It all depends on the individual preferences of the owner, as well as on the intensity of the loads.

It is recommended to lay tiles or porcelain stoneware on the OSB floor according to the scheme.

- The layout of the room. The surface is divided into zones, preliminary dry laying is performed, the tiles are trimmed.

- Preparation of the solution. You can take a ready-made compound thick enough to spread with a notched trowel. If liquid nails, sealant are used, preparation is not required.

- Application of the solution. It fits from the center of the room. For 1 time, a volume is taken that is sufficient to accommodate 1-3 tiles. The elements themselves are also covered with a solution from the seamy side, with a thin layer.

- Installation of tiles. Each module is put into place according to the markings, knocked out with a rubber hammer. At the corners of the first tile, cross-shaped spacers are laid out to form the seams. The following items are laid out in level.

At the end of the installation, the tiles are left to dry. The setting time of the solution depends on the type of mixture. When it is fully seized, the cruciform spacers are removed, the seams are filled with sealant or grout. In the gaps along the walls, it is better to immediately use silicone waterproof compounds.

On the wall

Unlike floor tiles, wall tiles are much more diverse in their composition. Decorative bricks and clinker elements, panels and decors of various shapes and sizes are used here. All this makes the layout more complicated, therefore, when performing the first work on your own, it is better to give preference to the simplest tile options - square, small in size.

Installation procedure.

- Markup. It is made taking into account the seam allowances according to the thickness of the cruciform inlays.

- Installation of the guide. It can be a regular aluminum profile. It is attached to the bottom edge of the second row. It is from here that the work will be carried out. In this case, you do not have to place the trimmed parts at the top.

- Application of the mixture. It can only be applied to the tile from the seamy side or also to the base. Each element is aligned with level and markup.

- Bonding tiles. During installation, cross-shaped spacers are inserted between the elements. The tiles themselves are knocked out with a rubber mallet. No more than 3 rows are laid out at a time, otherwise the offset will begin. Excess mixture is wiped off with a sponge.

Upon completion of the work, the bottom row of the coating is laid out, it can be supplemented with a border or other decorative elements. Drying is carried out at room temperature until the glue hardens completely. After that, you can wait 2-3 days, and then move on to grouting.

For more information on laying tiles on OSB plates, see the next video.

The comment was sent successfully.