Laying OSB-boards on a wooden floor

Having decided to lay the floor in an apartment or a country house without hiring craftsmen, you will have to smash your head with the choice of the appropriate material intended for such purposes. Recently, OSB floor slabs have been especially popular. In this article, we will take a closer look at all the basic subtleties of fixing the material to the wood floor.

Requirements for OSB-plate

This chip material resembles a multi-layer cake with three or more layers. The upper, lower parts are formed from a wood chip base by pressing. A feature of the material is the way of stacking chip parts, which are placed along the sheet in the outer layers, and in the inner layers are located transversely. The entire chip structure is strengthened by impregnation with special compounds: most often it is treated with wax, boric acid or resinous substances.

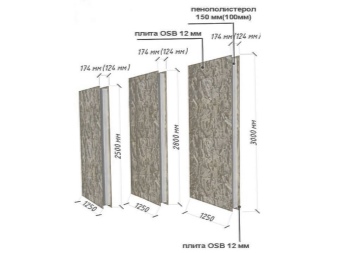

Between some layers, special insulation inserts made of expanded polystyrene are installed. The purchase of a slab for laying on a wooden floor should be approached as responsibly as possible. Taking into account the number of layers of chips and coarse shavings, this material has different thicknesses. Fasteners are firmly held in such sheets, they have more moisture resistant characteristics compared to the conventional wood-shaving option.

When choosing panels designed for wood flooring, you need to take into account all the main advantages and disadvantages of the material.

Pros:

-

environmentally friendly product with a natural wood base;

-

resistance to temperature changes and deformation;

-

high strength and flexibility of the flooring;

-

ease of processing, as well as installation of the sheet;

-

pleasant appearance and homogeneous structure;

-

perfectly flat surface;

-

relatively low price.

Minuses:

-

use in the composition of phenolic components.

A serious requirement when choosing a slab is a certain thickness, which depends on the following criteria:

-

for OSB flooring on a rough concrete base, a sheet with a thickness of only 10 mm will be enough;

-

for fixing the material to a floor made of wood, you should choose workpieces with a thickness of 15 to 25 mm.

When performing rough operations on construction sites, the thickness of the floor panel can range from 6 to 25 mm, depending on several requirements:

-

the brand of the selected shields;

-

indicators of future load;

-

distance between lags.

Only if all the requirements are met will it be possible to achieve the highest quality result.

Tools and materials

Having made the decision to lay the surface with such plates with your own hands, you need to carefully prepare for the upcoming operation. This requires a specific list of tools and materials.

Instruments:

-

jigsaw and puncher;

- electric screwdriver to fasten parts;

- hammer;

- level and tape measure.

You should take care of purchasing fasteners - self-tapping screws for wood, dowels. Before carrying out the operation, it is imperative to prepare some materials:

-

OSB plates and skirting boards for them;

-

insulation material (polystyrene, mineral wool);

-

logs made of wood;

-

assembly foam and glue;

-

varnish for application to the base under the topcoat.

And you may also need staining compounds used as a decorative finish.

Step-by-step instruction

OSB sheets can be laid directly on a concrete surface or simply laid on logs. If you will lay the material on an old wooden floor, then you should level the surface in advance. Installation technology in a particular case will be individual. Next, we will examine each option in more detail.

On the old wooden floor

Before starting this process, you should carefully prepare, considering some important requirements.

-

When planning the laying of laminate, parquet, linoleum or tiles, such sheets should be placed so that there is no coincidence of the joints of the flooring products with the joints of OSB boards.

-

If you do not want to calculate the location of the flooring parts, you can choose a transverse view of the flooring. In this case, the joints of the finishing flooring parts will be located at an angle of 90 degrees to the joints of the base plates.

-

And you can also make a choice in favor of a diagonal location of the topcoat at an angle of 45 degrees. This option is well suited for rooms with uneven walls, where it is planned to lay laminated boards in the future. This will hide the existing imperfections in the geometry of the room.

-

Before screwing on the material, be sure to check the corners for evenness. It is preferable to start the installation operation from the most even angle.

-

In case of divergence of the walls of the room in the form of a trapezoid, it is necessary to preliminarily make an accurate marking, followed by adjustment of the slabs laid along the walls.

-

Using a hammer and a bolt, all nails on the floor surface should be driven deeper into the board. Uneven areas must be removed with a planer, achieving the smoothest, even surface.

-

It is recommended to treat the old surface and the lower part of the sheet with an antiseptic.

-

Install a special substrate under the stove to prevent condensation from forming on the sheets in order to prevent them from aging in the future. The insulation is fastened with glue or shot with a stapler.

-

Mark and cut the slab for installation in a diagonal order, in order to avoid distortions and inaccuracies of fixation. Cut off those edges of the sheet material that will adjoin the walls.

-

Fasten the OSB shields with special wood screws. Screw in the hardware in rows, placing the underlying boards in the middle. To prevent splitting of the wooden material along the fibers, the nearest fasteners should be slightly displaced in a checkerboard pattern. The distance from the edge of the sheet to the row of fasteners should be 5 cm, the step in the line should be 30 cm, and the interval between the rows should be within 40-65 cm.

-

The holes for the self-tapping screws are countersunk in advance to install them flush. This will help prevent damage to future finishing layers.

-

In the case of using the coating as subfloors, all seams should be filled with polyurethane foam, the protruding parts of which are removed after final fixation.

Laying OSB on logs

It is quite possible to build a structure on your own, without involving professionals. The most difficult part when carrying out such an operation is building a strong supporting frame. The timber, in order to perform the bearing logs, must be of a certain thickness. Optimally - at least 5 cm.Their width, depending on the distance between them and the future load, should be 3 cm. Next, step-by-step installation steps are performed:

-

all wooden components that will be hidden under the floor covering must be treated with a special antiseptic solution;

-

the logs should be located in level in a parallel direction to each other with a predetermined step;

-

in the case of floor insulation, it is necessary to take into account the width of the heat-insulating product, whether in a roll or in a slab;

-

supports located at the edges should be laid at a distance of 15-20 cm from the walls;

-

the plates are placed on the logs for measuring and cutting, as well as for marking lines of transverse joints between the workpieces on them;

-

focusing on the line, they securely mount the transverse parts of the frame;

-

the level of each detail is adjusted with the help of special pads made of plastic or wood chips;

-

in the grooves of the finished frame, the appropriate material for insulation is placed or poured.

As in the previous version, such sheets should be laid in a checkerboard pattern, receding from the wall, as well as from each other. The perimeter of the room is filled with polyurethane foam.

Finishing

After all the correctly performed procedures for laying OSB sheets, the floors can not be covered with decorative material, but rather use paint or transparent varnish. The order of finishing the installed plates should be strictly observed, which consists in certain actions.

-

First, using a sealant, putty, you need to fill the gaps between the shields and seal the fastening holes with the caps of the self-tapping screws. In case of further varnishing, the composition should be chosen to match the wood.

-

After the putty dries, the places treated with it should be sanded. Next, it is worth removing the formed dust and other debris from their surface.

-

It is necessary to prime the surface of the sheets. Then you need to putty the entire area with a special acrylic-based putty.

-

After priming and puttying, you need to carry out another grinding procedure, followed by the removal of the dust that has appeared.

-

The next step is painting or applying parquet varnish.

-

The paint is applied in two layers, between which must be drying.

For finishing the floor, it is recommended to use compounds from one manufacturer. When using varnish, it is recommended to apply the initial coat with a brush or roller. After drying, slightly moisten the varnished surface and walk with a wide spatula, removing small roughness. During the final finishing work, a small amount of varnish is poured onto the floor, it must be leveled with a spatula with wide movements, so that in the end an even and thin layer is obtained. All finishing work should be carried out at air temperature values above 5 degrees Celsius.

Now, having an idea of such a material as an OSB-plate, even a non-professional will be able to carry out repair work, which, upon completion, will delight its owner.

Laying OSB boards on a wooden floor in the video below.

The comment was sent successfully.