What and how to paint OSB indoors?

Oriented strand boards are often used in the construction industry. They have an affordable cost, a long service life and good technical characteristics. OSB is made from large-sized wood chips, it makes up about 90% of the total mass. Resins or paraffin-wax impregnations are used as a binder. For greater decorativeness and protection, additional paints and varnishes are used.

Interior paints overview

Cover the ceiling and walls in the room with a safe composition, taking into account environmental requirements. Not all polymer-based paints and varnishes are suitable for indoor use, some of them release toxins into the air. In the house, you need to use only those compounds that will not harm. When choosing a paint, you should take into account the following nuances:

- the type of plate, which directly depends on the size of the chips used for manufacturing;

- method of processing, smoothing or preservation of texture;

- the surface on which the slabs are located;

- features of the indoor climate.

After evaluating these criteria, you can proceed to the selection of the coloring composition. It is important that the coating can handle the stress and conditions.

If we are talking about slabs on the floor, then it is necessary to choose a composition that is not afraid of water and detergents.

Recommendations to consider when choosing.

- Since OSB is made from natural wood material, it is oil paints can be used everywhere. The main component of the composition is drying oil. It prevents material from being absorbed into the board, which significantly reduces consumption. The paint not only decorates OSB, but also protects it with a rather thick and durable layer. This is a good solution for finishing your floor.

- Alkyd compounds usually used for painting wall and floor tiles. They also allow you to enjoy a strong and durable finish. However, the paint consumption is significant, so such coloring will not be economical.

- Water-based compositions. They are bad for high humidity. A good solution for wall treatment. However, it is not worth using the composition in the bathroom or in the kitchen. Can be used for painting walls in rooms with dry microclimate. The composition is non-toxic and completely safe for health. The paint can be used in the bedroom and nursery without the slightest risk.

- Polyurethane based paint great for rooms with high humidity. The coating is durable and resistant to the external environment. This is due to the special composition, which also contains resins.

- Transparent water-based varnish will preserve the texture and color of the slab. At the same time, the OSB will be reliably protected from moisture, ultraviolet radiation and mechanical stress.

- Epoxy composition can be applied to boards that are a finishing floor covering. So the surface will be perfectly smooth, and the appearance will remain natural. There are also pigmented compositions with high decorative effect. Chips or glitter are often added to this resin for decoration.

Acrylic

Disperse compositions are made on the basis of polyacrylates and their copolymers. As a result, a film forms on the surface. Acrylic paint can be used to paint OSB indoors. Particularly good for covering floor panels. After drying, the composition protects the material from various influences.

Environmentally friendly and safe formulations have an affordable cost. The slab is reliably protected from moisture, so the flooring does not require special handling. The compositions are used not only for indoor but also for outdoor work. Work with this type of paint can even be carried out on a veranda or balcony.

Stain + varnish

Walls or ceilings in a room with a natural slab texture will look attractive and make the interior more comfortable. This combination of compositions is often used by designers. Stains with a patina effect work well to give the slab the desired color.

Vinyl or polyurethane-based varnish will protect the wood from aggressive environmental influences.

Other

The decorative finish not only decorates the surface, but also protects it from adverse conditions. When choosing, it is worth focusing on where the OSB is located. So, the floor and walls can be covered with washable material, but for the ceiling this is not so important.

You can cover the plate with such compositions.

- Polyurethane paints. They allow you to make on OSB not only a decorative, but also a protective layer. A good solution for interior decoration in any room.

- Latex paints. After drying, the coating is elastic and resistant to chemical detergents. The paint does not emit toxins, therefore it can be used inside the house. A good solution for flooring, because maintenance will be as simple as possible.

- Alkyd paints. Protect OSB from moisture and ultraviolet radiation, do not fade in the sun and dry quickly after staining. They are made on the basis of alkyd resins. A protective film forms on the surface of the slab. During work, good ventilation should be ensured, the composition has an unpleasant pungent odor.

- Oil paint. The consistency of the composition is thick, therefore a thick coating layer forms on the slab. A good solution for processing OSB ends, protects against moisture. This type of material has a pungent odor that disappears for a long time after drying. And the drying process itself takes longer, so the work takes longer.

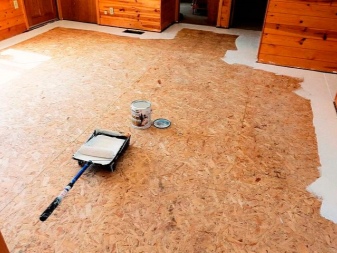

Preparation for painting

OSB is often used in the country as the main building material. Sheets are affordable, they show themselves well in use. The panels should be painted after installation. Correct preparation of sheets will provide a high-quality and durable coating that will not only decorate OSB, but also protect.

Procedure.

- Grinding. It is produced to smooth out the natural texture. Irregularities on the slab are due to the fact that large chips are used in the manufacture. The use of a sander is recommended. For uniformity, you will have to work carefully and for a long time. Deep grinding is necessary when using OSB-3 and OSB-4. Such models have a protective coating of varnish and wax, which will have to be removed completely.

- Smoothing unevenness with putty. The surface must be leveled before painting. Any grooves can be repaired with a suitable filler. In order to close up large holes, you can use an oil-based adhesive. With the help of such a putty, it is easy to repair the traces of mounting fasteners. Then the OSB should be sanded again. It is not recommended to use putty on the seams and joints that form at the border of the sheet. Such places still stand out even after staining. You can hide the joints only with the help of special decorative panels.

- Primer. Usually water-based varnishes with acrylic or polyurethane are used. In this case, the composition must be diluted according to the instructions. Usually, 10 liters of water is used for 1 liter of varnish, unless otherwise indicated in the instructions. Alternatively, an alkyd varnish is used. This composition is diluted with white spirit. The primer should be applied slowly and carefully so that the slab is thoroughly impregnated.When using light paint, it is important to ensure that no resin or essential oil stains appear on the surface. For this, an adhesive primer is used.

Step-by-step instruction

There are many options for staining OSB. You can use one color and make the surface completely smooth. Some people prefer to work without sanding and maintain the natural texture of the slab. The process is quite simple and the technology is not very different from any other surface treatment.

A large area is painted with a roller. It is possible to simply and beautifully cover the slab using multilayer technology. It takes a lot of time and patience, but the result is worth it.

Most often, the method is used for decorating flooring.

Below is a step-by-step instruction for staining with an imitation of natural stone.

- First, you should make a sketch of the design, and in color and graphic versions. This will greatly simplify further work.

- Completely paint over the slab with base paint. The lightest shade is selected. It is convenient to use a spray gun for application. So the composition will seep into all textured recesses and will not spoil the natural relief.

- At this stage, you can use a sander to highlight and accentuate the relief. However, this is optional.

- The entire area should be divided into elements, the shape of which corresponds to stones or some other objects. It all depends on the features of the chosen design. The markup can be done with a simple pencil, focusing on a previously drawn up diagram. Then with a brush you should outline the contours with paint, 4-5 shades darker than the base one.

- Each decorative piece should be painted in a different shade. The choice depends on the design and is strictly individual.

- Each element must be cleaned. It is not necessary to process the entire stone. You can simply rub on 1-2 sides to beat the volume.

- The contours of the stones should be drawn again. The same shade of paint is used as in the beginning.

- Allow to dry completely and cover with varnish. The base is selected based on the type of paint.

Such staining with imitation of other surfaces is time consuming and suitable for a creative person. However, it is not always possible to be so sophisticated. There is another way that even a beginner can easily handle. A good solution for slabs on the walls, only 2 paint colors can be used. Correctly perform the work according to this scheme.

- Apply pigment primer to the surface. It will be basic and will create an attractive finish. Usually a white polyurethane compound is used. Under normal conditions, the coating will dry in just 3-4 hours.

- After drying, sand the surface again and carefully remove all dust after that. It is best to use a vacuum cleaner.

- You can use the special "Pearl Effect" composition to create a subtle shine on the stove. Apply according to the manufacturer's instructions. It will take about an hour to dry.

- Use a spray gun to apply a patina that will slightly age the surface. After spraying paint, wait about 10 minutes and remove excess. For this, sandpaper type P320 is used. After that, all dust should be removed from the OSB again.

- In some cases, work can be finished already at this stage. The slab turns out to be attractive and effective.

- Now more important work begins. Mix colored acrylic varnish with stain and spray on OSB. The latter can be replaced with another composition, paint. The varnish should be taken without gloss. It will take about 1.5 hours to dry.

- During the drying process, the color may change slightly, and the board itself will become more dull. This should be taken into account when choosing materials.

- The topcoat can be done by anyone. Matte or glossy varnishes are used. A soft-touch composition is popular for treating walls, which creates a matte elastic coating that resembles rubber.

When choosing a staining technology, you should be guided by your own skills.

Very attractive designs can be created based on OSB. It is possible to decorate surfaces with drawings, to preserve the texture of wood. The choice depends solely on the interior, because all elements must be in harmony with each other.

The comment was sent successfully.