Choosing a glue for plexiglass

Adhesives are in great demand and are often used at home. The market offers a wide range of such products. If you need to work with plexiglass, you need to choose a special glue that has a number of technical characteristics and has a lot of advantages. This composition is presented in several varieties, so it is necessary to study their detailed description to find the one that meets your specific requirements.

Peculiarities

Plexiglass, commonly referred to as plexiglass, differs in pliability, therefore it is very pleasant and easy to work with him. This material is used for the manufacture of various containers and products, while special compounds are required to connect the elements. The result of gluing should not only be positive, but also strong, while it would be desirable that no muddy traces remain on the plexiglass, and the integrity was ensured. Experts recommend using different adhesives, which are offered in a wide range.

Working with plexiglass and glue can give different results, depending on the method of application, the characteristics of the composition, components and other factors. Here it is important to name two groups into which the products for joining plexiglass structures are divided. The first includes strong organic solvents, which include an acrylic filler. Their main advantage is that the fusion is not just strong, but homogeneous, since the seams are created by dissolving the plexiglass itself. This option is used in cases where you want to get the perfect result without disturbing the presentability of the plexiglass product.

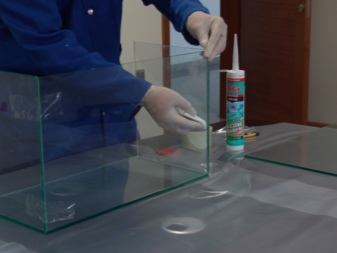

The second group includes adhesives made from epoxy resins, which are often used to seal cracks and crevices. Such compositions are quite in demand in case of repair. However, a small disadvantage is the duration of the drying process, but this is covered by increased resistance to stress.

With epoxy resins, the material bonds so well that you don't have to worry about cracks.

Types and their composition

Structures that include many parts cannot be assembled without the use of adhesives. In this case, it is important to make sure that the seams of the glued elements are strong, taking into account the strength of the material. When choosing such products, it is necessary to pay attention to all indicators, as well as to study the composition of the product in order to find what will meet all the requirements.

Physical adhesion is achieved with the products that are offered in the form of solutions... With the gradual evaporation of the solvents, the glue mass will become solid, which indicates the connection of the plexiglass parts.

With regard to chemical action, this includes all two-component formulations. The components are mixed, after which they begin to act and harden quickly. To obtain the desired effect, several factors must be taken into account - high temperature, combination of ingredients, introduction of catalysts or activating components, without which the reaction is impossible.

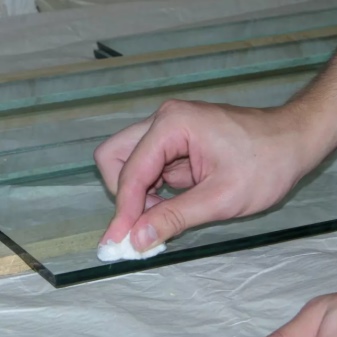

If you need to repair a plexiglass structure at home, the question immediately arises of which means to choose so that the result is of high quality, and the seams are strong and resistant to possible damage.Previously, dichloroethane was in great demand, which was applied to the surface of the material and dissolved it. When dried, the parts turned into a solid structure, and the seam was barely noticeable, and if necessary, it could be removed and the surface polished.

It should be noted that dichloroethane-based products are highly toxic and volatile, but they are considered one of the best for working with plexiglass. Today, the market offers mixtures with innovative components in the composition that are safe, so they can be safely used even at home.

Suitable for simple joining of Plexiglas parts ordinary glue "Moment". Its main advantage is that it responds quickly and can connect surfaces of a wide variety of materials. Of course, it is necessary to work with this tool carefully, precisely gluing the elements, because it will no longer be possible to separate them, since the integrity will be violated.

If you need the ability to adjust, you can select waterproof glue brand "88", which has increased strength. Liquid nails are considered a versatile tool that is suitable for home repairs. The only drawback is that the seam will not be transparent, so this factor must be taken into account in advance.

Dichloroethane often used to make an adhesive at home. The components should be not only this chemical, but also plexiglass shavings, which are mixed to a state of medium density. After a couple of days, the chips dissolve, and the mass can be used to glue the parts. Such a dichloroethane composition is capable of tightly combining Plexiglas elements by the accretion of molecules with each other. As a result, the seam will be strong, uniform and transparent.

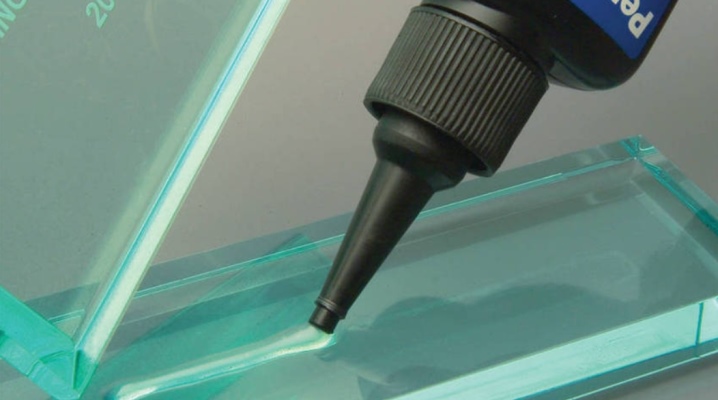

UV glue contains methacrylate, the hardener is ultraviolet, which emits a special flashlight. You can use such a substance for gluing not only plexiglass, but also metal, wood, plastic and much more.

The main advantages include resistance to temperature extremes, mechanical stress, transparent seam and its long-term preservation.

Brand overview

There are many brands of adhesives on the market that are suitable for working with plexiglass, but they differ in strength, transparency and have their own characteristics.

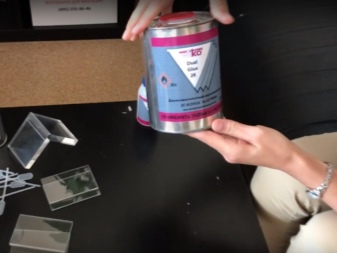

Substance Acrifix 117 is in great demand due to its high seam strength, transparency and durability. The glue sets quickly, does not evaporate toxins, and is also offered at an affordable price. Due to its capillary properties, the composition easily penetrates into narrow cracks and crevices, correcting material defects. For home use, such glue is quite expensive, moreover, it is offered in liter containers, and is also not sold in every store. That's why it is often used by professionals, repairmen, as well as various factories and manufacturing enterprises.

Acrifix 116 offered in convenient and compact containers. In terms of density, the substance resembles bee honey, but the seams will be transparent. This glue is best used on uneven and rough surfaces, as it can fill in depressions and pits in the material.

Adhesive options Colacril-20 and Colacril-30 are a good replacement for the aforementioned means, which are somewhat expensive. It is worth noting that these two compositions are most often used together by mixing, due to the fact that the first glue is more liquid, and the second is thick. The quality of gluing with such products will be at the highest level, moreover, the seam will remain transparent and invisible.

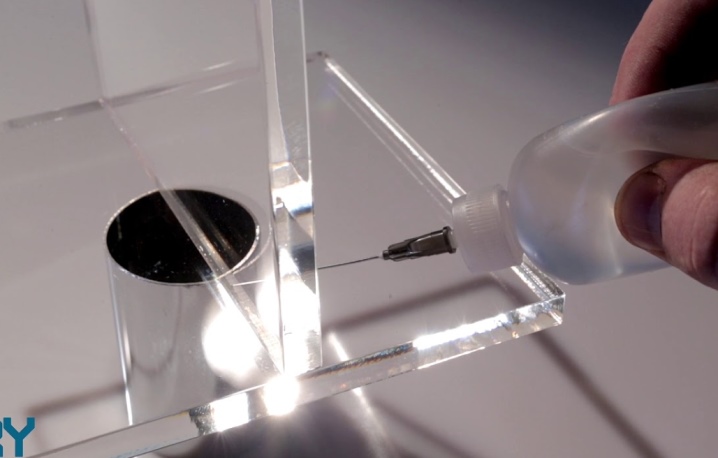

Moment glue, like Cosmofen, can be found in any hardware store. A big plus is that they are offered in compact packages with a spout, so filling cracks with this glue is very convenient.The composition contains cyanoacrylate, and the main feature is that these products do not dissolve the material, therefore, for greater strength, it is better to choose something else. Often, instant glue is suitable for repairing small parts in toys, where there will be no mechanical stress.

It should be remembered that the seam whitens, therefore, the presentability of the product is somewhat disturbed.

Which is better?

There is a wide variety of adhesives on the market that are suitable for materials such as plexiglass. However, it is not easy to name the product that is the best, because each has its own characteristics and advantages. Since the properties are very similar, the main difference is the ability to dissolve or not dissolve the material, which affects the quality of the joint.

First of all, you need to decide what exactly needs to be glued, and whether there will be a load on the plexiglass product. If we are talking about a toy or a decorative element, you can use the usual Moment glue, which is offered in any store.

If you need to process something dimensional and achieve increased strength, as well as make sure the seam is transparent, you should choose more expensive products with appropriate characteristics.

Dichloroethane is suitable for repairing aquariums, as it is airtight, adheres well, and at the same time non-toxic, which is extremely important for the life and safety of fish. However, it is necessary to work with such glue in a well-ventilated area, and the product should be used only after the substance has completely hardened and dried, which takes a month.

If you need to attach metal or wood to plexiglass parts, you need to choose adhesives that will cope with this task. These include "88" brand products, liquid nails and the same dichloroethane. Summing up, it is safe to say that dichloroethane is considered the most versatile, so you can safely use it for acrylic glass or plexiglass.

The next video shows you how to glue plexiglass.

The comment was sent successfully.