How and with what to glue plexiglass?

Plexiglas has long been considered a popular material for repair enthusiasts, creative individuals and those who have to deal with it in terms of the specifics of their activities. It decorates the details of household items, is used in interior finds, both aquariums and advertising signs are made from it. Interesting souvenirs and many other things are produced from plexiglass. And this material is also popular because it is easily glued if necessary, relatively easily fixed to other materials.

Fundamental rules

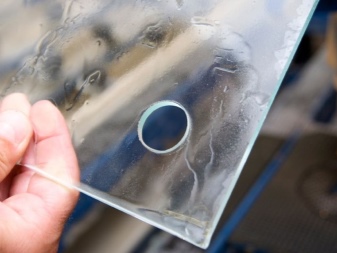

Plexiglas is called transparent plastic, which is obtained through the polymerization of methyl methacrylate. And although officially the abbreviation of the material is PMMA, the name plexiglass or plexiglass (Plexiglas) was fixed in everyday life. It is also sometimes called acrylic glass, acrylite. It is one of the most popular polymers with high strength, flexibility and good light transmittance. Unlike regular glass, it is easier to drill, cut or glue. It is also more difficult to break because it is considered safer.

For gluing plexiglass, specialized compounds can be used - based on acrylic fillers and based on epoxy resins. Since the material can be dissolved, accordingly, the gluing of plexiglass is possible under the action of acids: formic and acetic, for example.

How can transparent plexiglass parts fit together when gluing:

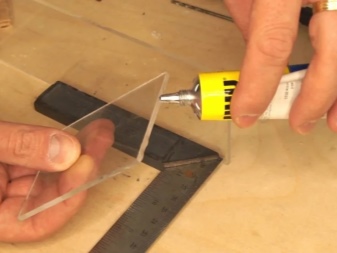

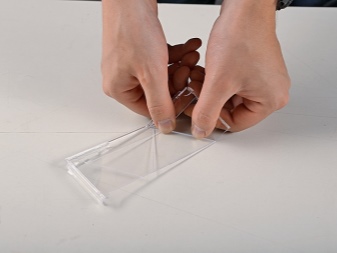

- on the mustache - this means that the edges of the blanks are cut off at an angle of 45 degrees, the parts are connected at right angles (for example, parts of picture frames are combined);

- overlap - the fragments to be glued slightly overlap each other at the connection point, and the increased contact area of the parts ensures load distribution;

- into tongue - there is a protrusion on one of the fragments to be connected, it enters the recess that is on the other fragment (groove principle);

- butt - in this case, the fragments to be glued touch each other with their ends, and the strength of such a connection depends on what the characteristics of the contacting surfaces are, and what kind of glue is chosen (aquariums are made in this way, without a seam);

- with pad - the fragments in this version are also connected by their ends, but an overlay is attached over the docking place to enhance fixation.

You can repair the glass at home, and the parts after the repair will not lose their original properties. It so happens that the purpose of gluing is simply to tightly connect the parts (and seamlessly), but a person is so drawn out of the process that he begins to make household items from acrylite. With your own hands, without the use of expensive tools.

The ways

There are several of them, the choice will be based on a specific task, the availability of materials and compositions, the convenience of this method for a person.

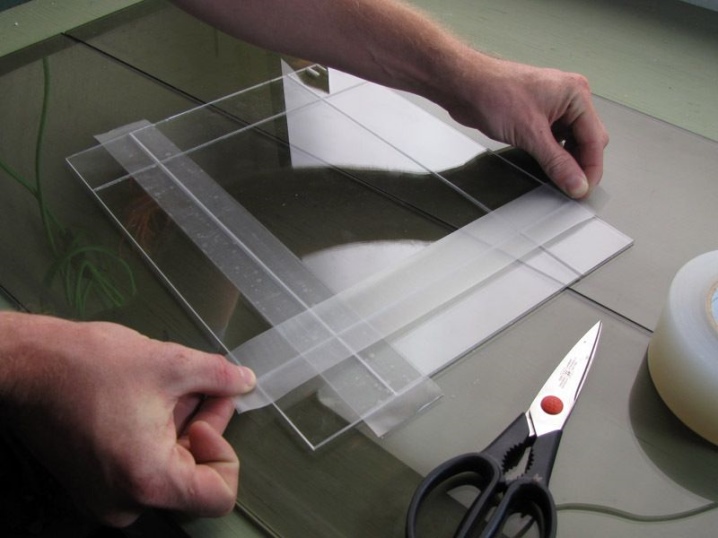

Adhesive films

Smooth and flat surfaces can be perfectly bonded with self-adhesive rolls. Such films are used in work with materials that, when heated, have a low expansion rate.

Films for plexiglass repair can be of several types.

- Double sided without base. Simply put, this is a layer of glue, also covered with a protective layer on both sides. To connect the surfaces, first, the protective strip is removed from one side - and fixed to the base. Then the protective layer is carefully removed from the other side. And between the glued fragments, as a result, one adhesive layer remains.

- Polyester / PP film. If you have to adjust the work, such material is better removed, which in some cases is an extremely important option. The film itself is thicker than the double-sided version, and when viewed from plexiglass, it will be more noticeable.

- Double-sided foamed film. In such films, the thickness reaches 4 mm. Usually they have to glue surfaces with noticeable irregularities, with drops of up to 7 mm. This applies to those items that suffer from vibration loads.

There is not always a choice, so you have to take the adhesive film that is available. Fortunately, in principle, each of the suitable compositions is not bad for sealing a crack, for example.

Ready glue

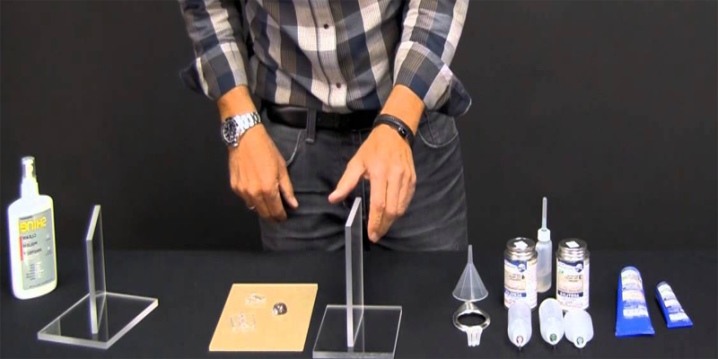

There are a lot of popular compounds for gluing plexiglass, there are enough manufacturers in this market.

Several products are considered the most in demand.

Acrifix 117 glue

Provides excellent bond strength as well as high transparency of the joint material. The composition sets very quickly, and when compared with dichloroethane, it is much less toxic. The glue has excellent penetrating power, so you don't have to squeeze the parts hard for better fixation. Well, the disadvantages, if we note them too, are the meager packaging option (sold only in liter containers) and a rather high price.

Dichloroethane

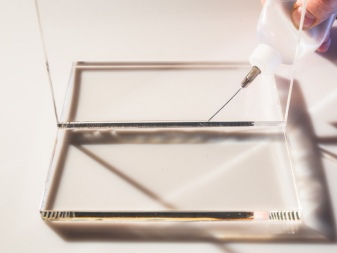

This is a budget alternative to the above glue. Usually you can buy such a composition in chemical supply stores, as well as in departments where radio parts are sold. The composition is drawn into a medical syringe and sent to the gap between the fragments to be joined. The seam will be perfectly straight, perfectly transparent. And if the surfaces are well prepared, not a single bubble will appear. But this only works with perfectly smooth surfaces. If they are not, then a little plexiglass sawdust is poured into the bottle with dichloroethane. They dissolve in the composition, a thick mixture is obtained at the exit, and it is conveniently applied with a wire or a small spatula.

Colacril 20/30 glue

These are ready-made adhesives that look quite affordable for the price. The adhesive with a 20 mark is very fluid, with a 30 mark it is more viscous. Experts advise to simply mix both adhesives and get the perfect consistency that will suit any type of joint. The seam promises to be smooth, beautiful, with no bubbles. But there is also a minus: in the place where the plexiglass bends, small cracks can form, and cause their internal mechanical stresses.

The strength of the connection will remain high, but the appearance of the fixation site may suffer.

Seconds glue "Moment"

This glue (like its many analogues) is produced on the basis of cyanoacrylate. It doesn't matter at all what this composition is packed into: in metal, plastic tubes or in bottles with a narrow spout - all these compositions are closely related. They are also united by the fact that they do not dissolve plexiglass, but create an adhesive intermediate layer. Therefore, you should not buy such an adhesive if the task is to fasten parts that are subject to stress. And the aesthetic characteristics of gluing are far from ideal - the seam will not be transparent, the place where the parts are bonded is visually noticeable.

Loxeal 30-11

It is a one-component formulation with light-curing characteristics. It is used if the seam must be highly durable and invisible. If you irradiate the bonding site with an ultraviolet lamp, the composition will set in 10 minutes, and full stabilization is possible within a day.

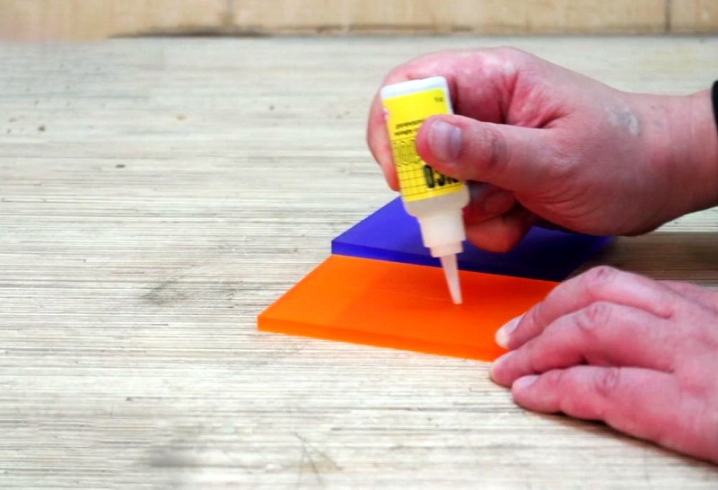

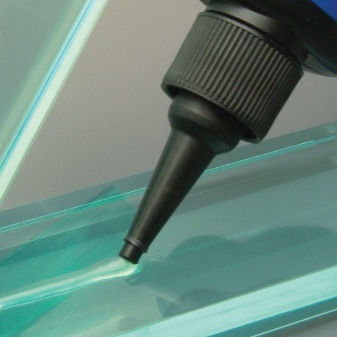

Let's take a look at how to work with ready-made glue.

- Smooth the surfaces with sandpaper. Check if the fixation fragments fit well together.

- Degrease the material with ethyl alcohol or kerosene. It is forbidden to use acetone - it will simply dissolve the plexiglass.

- Warm up the plexiglass a little - this will make it easier to remove traces of liquid.

- Apply the glue in a convenient way: either with a syringe, or with a wire, or with a small spatula.

- Fix the fragments to be connected motionless until completely dry.

- Remove the dried excess glue, after which the plexiglass must be cleaned and, of course, polished.

Improvised means

Needless to say, there are many craftsmen who are ready to glue plexiglass (sheet and not only) with improvised means at home. You can really make the mixture yourself.

The main components of home glue are organic solvent and plexiglass sawdust. The main component is acetone; it can be replaced with ethylene chloride or even acrylic glass dissolved in EDC. Plexiglass sawdust must be sent to the container with the selected solvent. This mixture is regularly stirred with a glass rod or wire loop.

How much sawdust exactly to add depends on how viscous the composition needs to be obtained.

Another affordable and interesting option for making home glue is ordinary foam as a base, diluted in 646 solvent. The principle of operation and composition of the glue is the same as in the case of plexiglass sawdust. Only the foam does not even have to be crumbled - it will dissolve on its own. When the components of the composition are well mixed, the adhesive will be infused for several hours so that the dissolution process is finally completed. And before use, this glue must be mixed again.

Vinegar essence is often cited as an example of an adhesive composition. But it can hardly be considered as a serious competitor to the above recipes. It creates a strong seam, but problems with its durability will arise. After such gluing, under strong mechanical stress, small but still noticeable cracks may appear on the entire surface. But small objects that are not subject to stress can in principle be glued together with essence.

Needless to say, such glue will cost a penny.

How to glue to other materials?

Sometimes it becomes necessary to glue plexiglass to metal or wood. For this, Moment glue, 88 glue, and liquid nails are suitable.

Let's see how it works.

- Moment glue. Provides almost instant coupling of two surfaces, therefore it is important to immediately position the fastened elements correctly, since it may not be possible to make adjustments.

The work requires the utmost care and attention.

- Glue "88". This is actually a universal compound that adheres perfectly to acrylic glass both to wood and to metal. And although the coupling can also be called fast, but still a few seconds remain for a maneuver, therefore for people who are unsure of their agility in such a delicate matter, it is better to use such glue. The seam will be strong and secure.

- Liquid Nails. This line-up literally has no competitors. It sets quickly, the connection will be of the highest strength, therefore even very thick plexiglass will perfectly adhere to wood or metal with liquid nails.

But in order for the glue seam to solidify, indeed, reliably, no load should be applied to the glued structure for 24 hours.

It is better to glue Cosmoplast 500 or Cosmofen to plexiglass glass. These compounds are extremely resistant to thermal shock, and even if the object heats up during use, the glue line will not suffer.

Security measures

Do not forget about the high toxicity of these compounds. Absolutely all presented adhesive products are quite aggressive in terms of chemical activity. For humans, their components are certainly dangerous. You need to work with them only with gloves, and only in a ventilated area. After work, you need to leave the room, and ventilate the room itself for a long time.

Therefore, these rules are always fulfilled when working on gluing plexiglass:

- good ventilation of the room;

- inclusion of forced ventilation, if work is carried out specifically with ethylene chloride;

- you need to work not only with gloves, but also preferably with goggles.

Attention! If the adhesive composition gets on the skin or mucous membranes, you should immediately seek qualified medical help. And to the doctor, show a package with glue that has got on a part of the body, so that the doctor understands how to act.

Effective and safe work!

For information on how and what to glue plexiglass, see the next video.

The comment was sent successfully.