All about colored organic glass

Colored organic glass is an acrylic sheet, which is a plastic polymer with a low weight. This material is conventionally called glass - it has a transparency characteristic of glass.

In addition to translucent specimens, you can find on sale both matte and light-diffusing options in various colors.

An excursion into history

For the first time, plexiglass was created in Germany in the XX century, in the period between the two world wars. At that moment and some time after plexiglass was called "plexiglass", since it was under this brand that the German chemist Otto Röhm patented it.

Industrial production of this material from thermoplastic acrylic resin began in the early 1930s. It was found that such a substitute for conventional glass has a lot of advantages and is perfect, first of all, for aviation - the safety of the cockpit was ensured by increased strength and the absence of sharp fragments when plexiglass was destroyed.

Soon, this transparent material found application in all types of military equipment - in addition to aviation, waterborne and ground. but Already during the Second World War, it was discovered that plexiglass, in addition to its advantages, also has a significant disadvantage - it is highly flammable. It is clear that for military aviation, this disadvantage fundamentally crossed out the advantages of acrylic polymer, and designers began to turn to other transparent materials.

However, plexiglass, and especially colored glass, later found application in almost all areas of human life - from construction and design to optics, medicine and agriculture.

Features and production

Colored versions of plexiglass are obtained by various additives to the main raw material - acrylic resin. There are two methods for the production of plexiglass:

- casting (block method) - the molten raw material with the necessary additives is poured into a mold for further polymerization;

- extrusion (extrusion method) - the hot mass passes between two fixtures, forming a thin sheet, which is subsequently cooled and cut into various shapes.

The texture of colored plexiglass may differ, due to which the material is widely demanded in the design of premises.

Modern production offers consumers, in addition to glossy matte panels, with a texture in the form of waves, crumpled paper, compressed leather, velvet fabric, pieces of ice, drops, honeycombs.

Advantages and disadvantages

The main difference between sheet acrylic and ordinary glass is that the material in question is easy to process:

- safe cutting and grinding (you can use a tool for cutting metal, the process of work is no more difficult than with wood);

- drilling holes without cracking for fastening to other elements;

- fixation with various types of glue (specialized adhesives, adhesive tapes for plexiglass, solutions based on glue and solvents);

- bending and shaping by heating (while the optical properties of the material do not change).

In addition, acrylic sheets have a number of advantages due to which they are widely demanded in the market.

- A light weight. Plexiglas weighs several times less than traditional glass with the same thickness and size.Thus, the acrylic sheet structure does not require reinforced supports or frames, which will not overload the space.

- High light transmittance - over 90%. At the same time, the material does not lend itself to ultraviolet radiation, retains its color, does not turn yellow, and does not form burnt spots on it.

- Impact strength. To break plexiglass, an impact force is required that is several times higher than that required to break ordinary glass. In addition, when broken, the material does not disintegrate into small sharp fragments.

- Resistance to biological and natural factors. Plexiglas does not destroy moisture, it is resistant to the growth of microorganisms, mold and fungus, therefore it is often used in wet rooms, in the production of water transport, aquariums. In addition, it has high frost resistance.

- Resistance to aggressive environments. The material demonstrates increased resistance to chemical compounds, due to which various household cleaning agents can be applied to the products.

As for the disadvantages, they are mainly associated with technological difficulties in the manufacture of products. In the domestic use of acrylic sheet, there are two main disadvantages.

- High flammability. As noted above, the material is highly flammable, therefore, for safety reasons, it is forbidden to use it near open flames, heating devices, as well as in baths. However, it should be noted that when ignited, plexiglass does not emit toxic substances, as it is environmentally friendly.

- Exposure to mechanical damage. The acrylic sheet often leaves unsightly scratches from sharp objects, so it is unreasonable to cover kitchen work surfaces with such a material.

Color spectrum

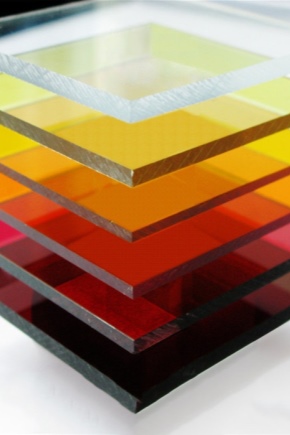

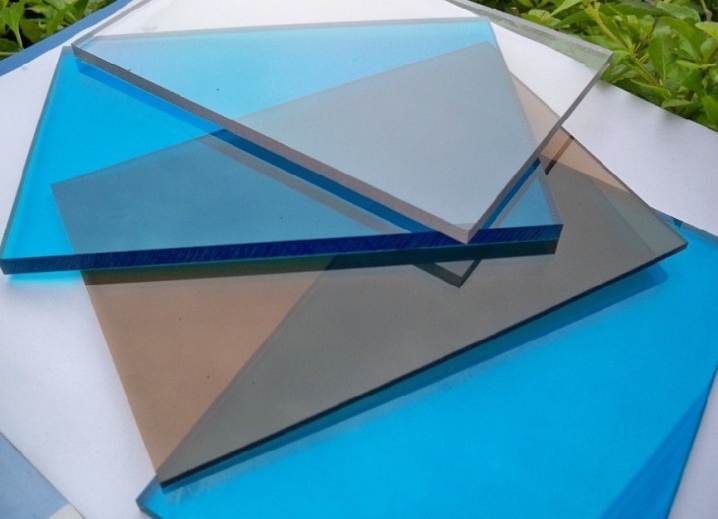

Colored glass is presented on the modern market in the widest color palette. On sale you can find options in classic colors - white and black acrylic glass, as well as all the traditional colors of the rainbow spectrum - from saturated to paler shades of red, green, blue, yellow, orange, purple, blue. At the same time, coloring substances in multi-colored glasses do not affect the degree of transparency and do not distort visibility through the glass.

According to the statistics of sales in interior design, the most popular types of colors are:

- white (beige, ivory, coffee with milk);

- brown (golden glow, dark bronze);

- gray (opal, silver, smoky).

The listed options are considered universal, not cutting the eyes, and therefore are suitable for decorating rooms in any style.

Along with transparent multi-colored glasses, matte varieties are also in demand. They perfectly diffuse light, they are often used for shades of lamps.

Another quality of frosted glass is that it is opaque, due to which it is used for the manufacture of screens, walls of shower cabins, office partitions.

Scope of application

Multi-colored acrylic glass can be found almost everywhere in the modern world. Plexiglas is used for interior decoration in the creation of shades for lamps, decorative pendants, shop windows, podiums, partitions in offices and apartments, aquariums, suspended ceilings. In street conditions, colored organic glass is often used in outdoor advertising, facade decoration, stained-glass windows, as domes for public transport stops.

In the manufacture of various structures, acrylic sheets of different thickness are used.

- 1.5 to 2 mm - the thinnest and most flexible version, used in the production of sunglasses, helmets and protective helmets, hard contact lenses, business card holders, badges, stands for advertising brochures.

- 3 to 5 mm - the scope of application affects advertising, but already in structures that require increased strength. These can be shop window elements, signboards, illuminated signs.Often, colored glass of this thickness is used in design structures, as well as in the design of car side windows.

- 6 to 10 mm - it is used for glazing of various kinds of structures - premises, verandas, canopies of yachts, domes of stops and subway entrances, stands for presentations.

- 12 to 20 mm - the densest variety of colored organic glass, used to create steps, podiums, stages, dance floors, pavilions.

Popular brands

Below are the top manufacturers that offer a variety of quality products at affordable prices. The price is indicated for an average sheet with a thickness of 3 mm.

- JSC "DOS". The Russian company supplies extruded organic glass with a glossy surface to the market. Primary colors are milky and luminescent varieties. The company also manufactures custom-made acrylic sheets in any color scheme. Price - within one and a half thousand rubles per square meter.

- SafPlast. Another Russian manufacturer offering extrusion glossy acrylic at a cost of 700-800 rubles per 1 sq. meter. The colors are white, yellow, red, blue and black.

- Evonik Industries AG. The German company is engaged in the manufacture of a wide range of acrylic sheets. Both cast and extrusion versions are available on the market. Matte, glossy, textured, mirrored pieces are presented. The color range is 250 different shades, including gold, silver and bronze. Price for 1 sq. m varies from 1.5 to 4.5 thousand rubles, depending on the series.

- Lucite International. Production - England, type of products - cast, colors - green, shades of red, black, blue, blue, yellow, orange. There are options with fluorescent shades. Cost for 1 sq. meter - 1200 rubles.

- Rexglass. The Taiwanese company exports molded organic glass in a variety of iridescent shades. The price is affordable - from 900 rubles per 1 sq. meter.

You can find out what acrylic or plexiglass is from the video below.

The comment was sent successfully.