What is plexiglass and where is it used?

For many years, organic glass has been the leading choice for many consumers. According to some craftsmen, this material can be considered the best among all types of plastic.

What is it and what is it made of?

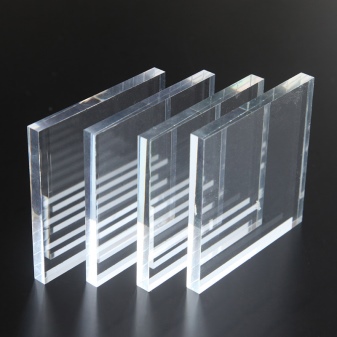

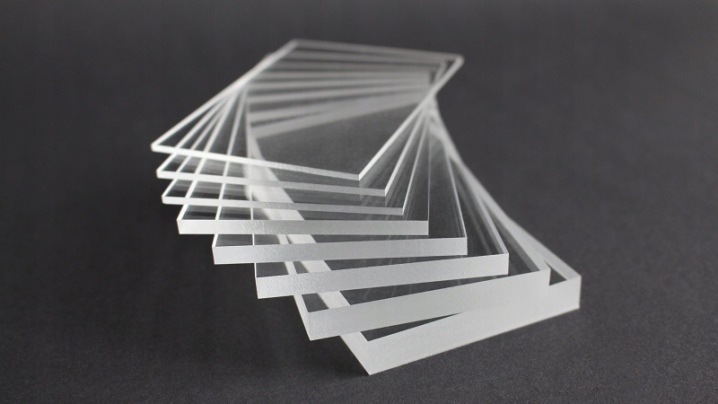

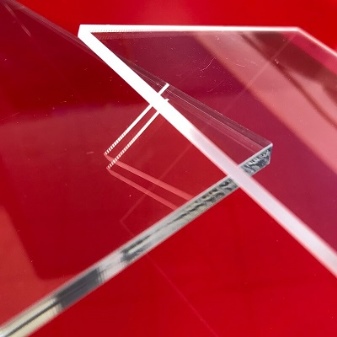

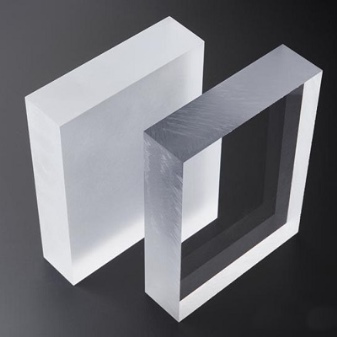

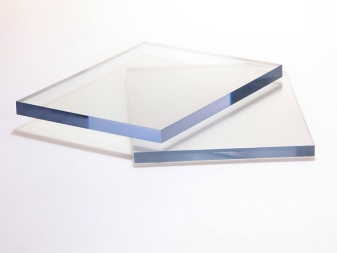

Plexiglas is a vinyl polymer in the form of a thermoplastic. It can be both colored and transparent. Organic glass differs from the usual glass by its special elasticity, thanks to which it does not break into the smallest fragments. Organic glass can be considered a transparent, light-transmitting or sun-scattering artificial material, in the manufacture of which special acrylic resins and additives are used. Methyl methacrylate polymer has the form of a thermoplastic resin that has hardened to the form of a powder or granules. It is produced in sheets and blocks with different thicknesses and sizes. It is often referred to as acrylite, metaplex, plexiglass and acrylic.

In the production process, sheets are obtained with different colors, namely: blue, red, green and others. According to GOST 17622 - 72, there are several brands of plexiglass:

- TOSP;

- TOSN.

This material is produced in two ways.

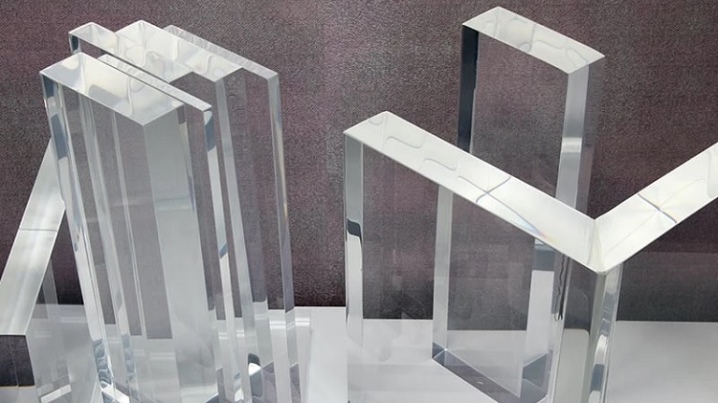

- Blocky. The polymer is obtained as a result of monomeric "filling" of the border between two special glasses. The monomers contain a hardener, dye and other components. After a while, the plexiglass is cut according to the required parameters.

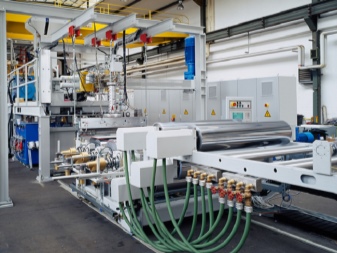

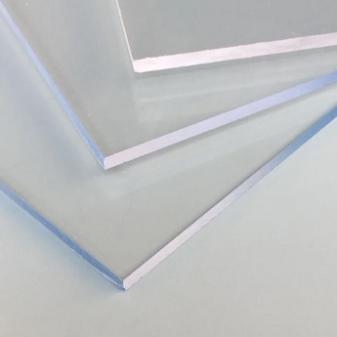

- Extrusion. This type of plexiglass is obtained by extrusion. To make the material, the granular polymethyl methacrylate is sent to an extrusion machine. There, the initial substance is heated to a viscous state, followed by extrusion into mirror calenders. The thickness of the sheets is directly influenced by the size of the gap between the calenders.

The chemical composition of organic glass is the same for all manufacturers. The molding process of plastic material is usually accompanied by qualitative changes in the form of compressed air and vacuum distribution.

This type of material has been used by people for 70 years. Today it is used all over the world in many industries.

Properties and characteristics

One of the main characteristics of an organic leaf is the ability to be presented in different forms, while its main quality characteristics are not violated. According to GOST, turbidity and distortion of the view are not allowed on the bending line of the sheet. The main technical characteristics of the material are the following:

- density - no more than 1.2 g / cm3;

- specific gravity - depends on the thickness of the sheet, on average 1190 kg / m3;

- dielectric constant - 3.5;

- thermal conductivity is low, it is 0.2-0.3 W / (m * K);

- transparency coefficient - 93%;

- heat resistance - 150 degrees Celsius;

- operating temperature - from 40 to 90 degrees Celsius.

The melting temperature of plexiglass is 150-190 degrees Celsius. Under these conditions, it softens and loses its original form. The polymer is characterized by ease of processing, the ability to drill, it is well cut. If it is necessary to give the material a certain shape, it is heated to add plasticity to the organic glass.This type of thermoplastic eliminates the presence of air bubbles, which contributes to its strength and uniform transparency. This product is realized matte and transparent, it is able to react neutral to chemicals.

The demand for the polymer is justified by its safety, non-combustible glass can withstand significant loads and has an optimal refractive index of light. Acids based on fluorine, nitrogen, sulfur, chromium and cyanide can affect acrylic glass. In addition, it is affected by methyl, butyl, propyl, ethyl alcohols. This polymer can be dissolved with chloroform, methylene chloride, dichloroethane. Transportation of organic thermoplastics can be carried out by various types of transport.

The storage of this material should be carried out in a dry, closed room with a temperature of +5 to +35 degrees Celsius.

Advantages and disadvantages

Plexiglas is a popular type of plastic that has many advantages over monolithic polycarbonate and other materials.

- Low thermal conductivity.

- High percentage of sunlight penetration. This qualitative characteristic of the polymer does not change over the years. In addition, with prolonged use, the plexiglass color does not change.

- High resistance to mechanical stress and shock.

- Light weight. Due to its low weight, the thermoplastic does not need additional supports.

- Does not deteriorate when exposed to high levels of humidity.

- Resistant to bacteria, mold and mildew, which is why it is often used in the production of floats and aquariums.

- Environmental safety, no harmful fumes.

- The ability to take different forms.

- Ease of machining.

- Frost resistance.

- The ability to transmit ultraviolet radiation, which ultimately does not cause yellowing and deformation.

- Resistant to many chemicals.

In addition to all of the above, plexiglass is recyclable. In addition to the advantages, this material also has some disadvantages:

- release of toxic methyl methacrylate during pyrolysis;

- tendency to damage the surface;

- the possibility of ignition at a temperature of 260 degrees Celsius.

How is it different from acrylic?

The difference between acrylic glass and organic glass is not very big. Acrylic is a thermoplastic type of polymer material that is produced on an acrylic basis. It is a lightweight, environmentally friendly polymer with good strength and low thermal conductivity. This durable material is easy to clean. All of the above features are inherent in plexiglass, so there are no special differences between these materials. It is observed only during the manufacturing process due to the use of certain types of additives.

Species overview

Today manufacturers offer the consumer a wide range of organic glass. There is a thin sheet, block, thick tinted anti-vandal glass on the market. The area of its use directly depends on the type of material. For example, patterned corrugated decorative glass is used for interior design. In the engineering, medical, and construction industries, transparent polymers are considered relevant.

Different types of plexiglass look different, they can be matte and colored. Often, consumers prefer light-scattering, tempered, cast, flexible, heat-resistant, heat-resistant, fluorescent, textured glass made by extrusion and other methods.

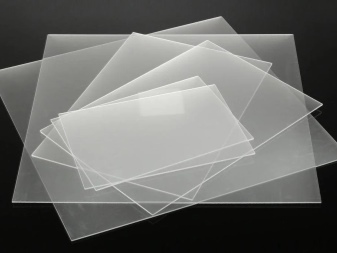

By transparency

Organic glass can be transparent, opaque or frosted. The first type of product has a high light transmittance. It is characterized by double-sided smoothness and shine. The thickness of this material is 5 mm. Frosted milk glass transmits light by 20-70%.

In order to achieve haze, the manufacturer significantly reduces the transparency of the polymer.Due to this feature, the matting layer does not scrape off the surface during cleaning.

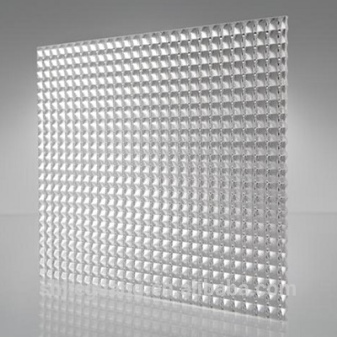

By surface type

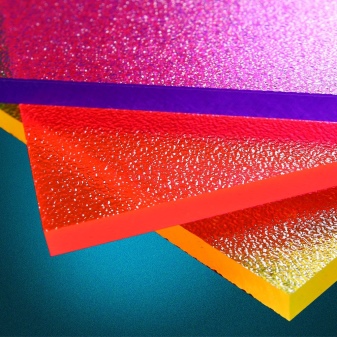

By type, the surface of plexiglass is smooth and corrugated. A material with a grooved surface is inherent in waviness and the presence of geometric protrusions. Often this material is produced with a matte surface. The relief of glass can distort the optical properties of the product, as well as reduce its transparency.

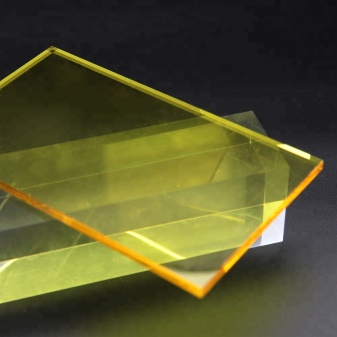

By color

Colored organic glass is available in a variety of colors and shades. The material is blue, red, yellow, silver, golden, black. This polymer is both transparent and uniformly colored on both sides. Currently, light blue, brown, smoky glass is considered especially popular. The corrugated colored product can be decorated with such patterns as drops, crushed ice, waves, honeycombs.

Top manufacturers

Since the demand for organic glass is growing every year, many companies in Russia and abroad have begun to produce it. Let's note the most famous brands of this thermoplastic, popular all over the world.

- Plexiglas. The products of this brand are sold in a wide range. The polymer is manufactured by casting and extrusion. The product line is characterized by a wide range of colors.

- Irpen sells many varieties of organic glass. The line includes both regular and colored fluorescent material.

- Quinn plastics - this manufacturer sells high-quality matte and glossy plexiglass.

Organic polymer in sheets is represented by the following types:

- SE - extrusion;

- SB - block;

- SEP - transparent, made by extrusion;

- SBS - block fire-resistant type;

- SBPT - block with high heat resistance.

Applications

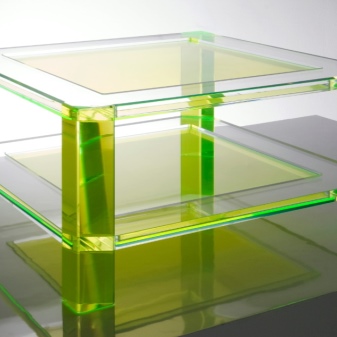

Organic glass has found its application in many areas of human life. This material can be found at home, in the interior. For example, it is used for kitchen countertops and roofing. The polymer is indispensable in aircraft and automobile construction, in devices and machine tools. With its help, they create large and small vessels, produce glazing.

Plastic glass is often found in construction and architecture. It can be used to make a high-quality fence, canopy, partition, internal and external structural elements. The characteristics of plexiglass contribute to the fact that it is often used by designers.

The material is used in the manufacture of furniture, lighting fixtures, stained-glass windows. Recently, polymer plumbing items have been in good demand.

Plexiglas is necessary for the production of equipment for exhibitions and shopping centers, as well as structures for advertising, signs and plates for the office. At present, it is difficult to do without this polymer in the manufacture of souvenirs, stands, tags, and numbers.

How to work with the material?

Plexiglass is quite easy to process, it can be easily cleaned, cut and tinted. This polymer can be cut with a metal hacksaw. However, in this case, you can spend a lot of effort and result in poor quality stitches. The best option for cutting plexiglass is considered to be the use of a cutter, which looks like a saw with one tooth. In addition, this thermoplastic can be cut using a circular saw or the scraping method using a glass shard.

The use of plexiglass is impossible without polishing it. Before proceeding with the procedure, it is necessary to prepare the surface; for this, with the help of fine emery paper, you need to sand all the irregularities. Experts advise using water when working. Manual polishing is carried out using a piece of flannel or a piece of woolen cloth, which are pre-lubricated with a polishing paste.The end of the work is carried out with the same cloth, but in an oiled form. To finish polishing faster, you can use a buffing wheel.

Forming organic glass possible at temperatures from 110 to 135 degrees above zero. Under such conditions, the polymer becomes plastic and bends well. When the temperature is lower, the thermoplastic becomes brittle and loses its quality characteristics.

To carry out the molding of plexiglass, you must use a plywood matrix or a wooden punch. The procedure should be carried out on the floor, in the company of a partner. When the material warms up, it should be removed from the oven and placed on the matrix. After 10 minutes, the finished product can be removed from the mold.

For gluing plexiglass use dichloroethane in pure form or dissolved with shavings. For the procedure, two surfaces are lubricated with a substance and pressed tightly, removing air bubbles. The bonding site should grasp in a couple of minutes.

For uniform coloration of thermoplastics it is recommended to polish the surface in advance, removing chips and scratches. The next step is to prepare a dye solution, which should contain alcohol and a dye. The organic glass product should be held in a heated dye solution, and then transferred to a container with cold water. After cooling, organic glass must be wiped dry with soft paper or cloth. At the end of the staining procedure, it is recommended to polish the polymer product.

Plexiglas is a versatile new generation material with a lot of advantages, therefore its popularity in the world is constantly growing.

For information on how to quickly and accurately cut plexiglass, see the next video.

The comment was sent successfully.