Description of reinforced glass and its application

Glazing of window and door openings is one of the stages of construction. Today, due to the fact that fires occur more and more often in residential buildings and industrial buildings, there are many requirements for materials. In order for the facility to be built to comply with the rules and regulations of fire safety, it is reinforced glass that is chosen for glazing. In addition, it reduces the risk of injury if it breaks. What this material is and where exactly it can be used - we will tell in this article.

What it is?

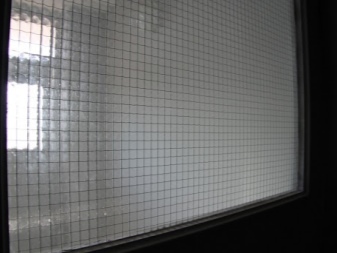

Reinforced glass refers to a sheet material, in the manufacture of which a metal wire is used. Inside the glass, it plays the role of an armature, due to which the structure can withstand very high temperatures and pressures.

Even if the glass has been broken, the fragments do not crumble, but remain on the metal mesh. Thus, it is possible to avoid situations hazardous to human health.

Reinforced glass is manufactured in accordance with the requirements of regulatory enactments, GOST. This material is characterized by:

- high fire resistance - it is this parameter that is the main and most significant, due to which this type of glass is most often used for glazing buildings with an increased level of fire hazard;

- reliability;

- impact resistance;

- resistance to mechanical and chemical influences;

- long service life.

As for the light transmittance, which is also regulated by GOST and must be at least 65%, it is only slightly (by several percent) reduced in comparison with ordinary glass.

The design has a number of features and advantages, among which the following should be noted.

- The presence of glass in window and door openings or as partitions makes it possible to prevent the spread of fire and smoke during a fire. Today, reinforced glass with a thermosetting film is very popular, the presence of which increases the fire safety of the material several times more.

- The presence of a metal mesh prevents intruders from entering the premises.

- Even if the glass itself is broken, the metal frame will remain in place.

Manufacturing process

The production of reinforced glass is a very laborious and complex process. This requires not only high-quality and modern materials and equipment, but also qualified specialists who have the knowledge and skills of work. This, one might say, is a piece of jewelry, because the master who does this must, with millimeter precision, put a metal mesh into the glass. The distance from the glass surface to the wire mesh may not exceed 15 mm.

Manufacturing takes place by injection molding on special machines under the influence of high temperature. Glass and wire are connected to each other and turn into a single monolithic structure, which has high strength characteristics.

The main materials from which the reinforced sheet is made are glass, the thickness of which is 6 mm (+4 mm) and wire. The latter must meet the requirements, namely:

- be made exclusively of mild steel;

- withstand high temperatures, be corrosion-resistant and not oxidize - this is necessary so that during the casting process under the influence of high temperatures it does not change color;

- diameter varies from 0.35 mm to 0.45 mm;

- two mesh sizes of the wire mesh are allowed - 12.5 mm * 12.5 mm and 25 mm * 25 mm.

At the request of the customer, the manufacturer can produce a grid, the cells of which will have a hexagonal shape.

Such a laborious and costly production process greatly affects the cost of the material. Compared to the cost of triplex, the price of wired glass is much higher.

Species overview

Currently, the enterprises produce several types of tempered reinforced glass, differing in their parameters. Let's take a closer look at all types and classifications of material.

Depending on the color

In terms of color, it is presented in the following forms.

- Transparent. This option is called classic. It can be installed absolutely anywhere.

- Colored. Only three colors are allowed - green, yellow and blue. In order to obtain one color or another, various metals are added to the molten glass in production.

- Multi-colored. This type is made exclusively for an individual order. The production technology is very complex, and the process itself takes a long time, so the price is appropriate.

By surface type

The surface of reinforced glass is:

- polished or unpolished (matte);

- patterned;

- embossed.

The type of surface also affects the cost of the material.

By type of reinforcing wire

In the process of manufacturing reinforced glass, according to GOST, it is allowed to use several types of reinforcing wire, namely:

- steel;

- chrome plated;

- nickel plated;

- with aluminum spraying.

Popular manufacturers

Today on the market of materials used for glazing, there is a wide selection of products from different manufacturers. Both large state-owned factories and private companies are engaged in the production of reinforced glass. Among all existing domestic manufacturers, it is worth noting:

- Modern Glass;

- Euroglass-Techno;

- JSC "BSZ" (at the moment the company is part of the largest Japanese concern for the production of reinforced glass Asahi Glass Company);

- LLC "Art Structure".

Each of the above companies manufactures modern and reliable products at their factories, the quality of which is confirmed by the availability of international certificates.

Applications

Earlier in the article, we already talked about the fact that reinforced glass is highly fire resistant, and that is why it is installed in buildings with increased fire safety requirements. It can be door, window, display. It is also used as a partition. For doors, a more durable and thicker glass unit is used.

In industrial buildings, the installation of reinforced glass is a prerequisite for fire safety. Also, this material is often installed in medical institutions - spans are glazed with it.

How to cut?

Cutting reinforced glass is as hard and demanding process as manufacturing it. There is a special machine for this.

Errors and inaccuracies are not allowed when cutting reinforced glass. The process consists of several stages:

- laying sheet material on the machine;

- marking and drawing cut lines;

- setting up equipment;

- then the machine cuts only glass, but the wire must be cut by hand using wire cutters;

- then the machine cuts the bottom of the glass.

After the work is completed, grout the edges of the finished product. They should be smooth and clear. Cracks and any other damage are not allowed on the surface, integrity must be maintained.

It is impossible to cut the reinforced glass on your own, for this you need to have special equipment and skills.

Description of reinforced glass and its application in the video below.

The comment was sent successfully.