Manual sprayers: principle of operation, types, advantages and disadvantages

On large plots of land, to facilitate the care of plants, special sprayers were invented, which, with the help of pressure, are able to spray liquid over long distances.

With the help of these devices, the active substances penetrate into hard-to-reach areas. In addition to its direct purpose, the sprayer can be used for cleaning equipment and spraying dyes.

To date, the design features of sprayers have expanded, distinguishing between models with gasoline and electric motors.

Let's take a closer look at which types of technique are best suited for working with plants, as well as how to create a sprayer yourself.

Features and working principle

Garden sprayers are simple in design.

Each model includes:

- fluid reservoir;

- pressure pump;

- filter;

- nozzle;

- hose;

- spray rod;

- fuse.

A hand sprayer is a small-sized pump or spray gun of various sizes.

The volumes of tanks for liquids are from 2 to 30 liters. At the same time, a volume of 10 liters is enough to process a plot of up to 30 acres.

To spray the substance from the tank onto the plants, you need to pump the pump yourself. In automatic sprayers, it is driven by a motor. Under the influence of the generated pressure of several atmospheres, finely dispersed water with drugs dissolved in it is released. The throw distance of the liquid depends on the force exerted on it. For hand-held sprayers, the throw is carried out from 1 to 10 meters.

Gasoline and electric garden sprayers have optional accessories that make gardening easier and more flexible.

They are equipped with shoulder straps for easy portability. Some sprayers are designed in the form of a backpack with a waist belt that allows you to secure the sprayer tightly on your back and reduce stress on your arms and joints.

Views

There are several types of hand held garden sprayers.

Pump-action

A pump sprayer is an apparatus in the form of a conventional pump, similar to a syringe or spray bottle. Consists of a plastic reservoir in the form of a cylinder with a pump handle or a removable spray lid. It is activated by pressing the trigger of the sprayer or by pushing the piston in pump sprayers. Some models are equipped with a button instead of a lever.

The volume of the tank is from 1 to 2 liters, since heavy devices are difficult to hold in your hands.

The design of hand sprayers also includes:

- a filter located in front of the nozzle that protects the sprayer from clogging;

- spray nozzle, fine atomization is adjusted by turning the nozzle in different directions;

- measuring scale;

- a drain valve designed to remove excess air in the tank.

Hand-held pump-type sprayers are used in small areas for local processing of trees and flowers.

Hydraulic

They have a reservoir with a volume of 3 to 12 liters. They are used for processing vegetation in gardens, in summer cottages. The sprayer is equipped with a shoulder strap for ease of movement.A fishing rod acts as a sprayer - a long thin hollow tube fixed to the tank with a rubber hose. Spraying is done by pressing a button.

The pump is located in the lid of the reservoir, creating a pressure of 4 atmospheres. On some models, the release button is equipped with a lock that locks the position of the button without requiring constant pressing, which makes it easier to spray for a long time.

Knapsack

The tank volume of knapsack sprayers varies from 10 to 20 liters, which allows you to process up to 50 acres of land.

The device is divided into two types: hand-held and cordless.

The first type is made as a pump pump, the pressure is created in the pump chamber, and not in the reservoir.

This placement allows you to protect a person from rupture of the chamber when pressure is generated, protecting against the ingress of a chemical solution on the skin and clothing.

The tanks are equipped with two shoulder straps to make it easier to carry equipment, and a waist belt is located at the bottom of the tank. The pump handle is located on the side, when the pressure in the tank decreases, it is convenient to hold the fishing rod with one hand, and with the other, to pump up the pressure. This ergonomics of the parts allows you not to remove the device in order to equalize the pressure in the tank.

In the case of the accumulator, the pressure build-up is carried out using an electric accumulator operating from a battery. The battery works without recharging up to 8 hours. This device is suitable for treating large areas without power supply.

Unlike motorized sprayers, cordless sprayers operate silently.

Pneumatic

Pneumatic sprayers are hand-held and portable. Spraying is carried out by building up pressure using a pump located in the cover of the unit. The cases of the devices are made of shock-resistant plastic, which affects the duration of the device's use.

Hand sprayers are equipped with a short spray nozzle that allows you to disinfect premises or spray hard-to-reach places.

In addition to manual sprayers, there are also motorized, mounted, herbicidal sprayers. They are mainly used in large areas.

- Motorized device equipped with a gasoline engine with a capacity of 1 to 6 liters. with. The distance of the solution ejection depends on the power of the engine, the range is 7-15 meters. Power and battery sprayers are self-contained units. The spray boom is shaped like a hose. The liquid spreads out in a jet by the action of an air stream.

- Attachments presented in the form of an additional device attached to a tractor or other large equipment. Equipped with a reservoir up to 1500 liters. Spraying is carried out using a piston diaphragm pump and fans. Air currents allow whole plants to be treated in large areas, which reduces the time of the procedure.

- Herbicide sprayers stand apart. This type of sprayer is a metal nozzle in the form of a slingshot, a special shape prevents damage to trees in contact with them. The design is fixed on special equipment operating over vast territories. The nozzles have protective screens that prevent excess liquid from being sprayed onto untreated areas. The ejection of the liquid is driven by an electric pump of the hydraulic mixer. The device is designed for root processing of vegetation.

Advantages and disadvantages

Each device has a number of disadvantages and positive aspects.

With pump sprayers, the disadvantage is the constant removal of the device from the back to pump up pressure, with other models - for refueling.

Pros of sprayers:

- devices are made of materials that can withstand high temperatures, which allows the use of hot preparations;

- ease of refueling process;

- adjustment of the jet of ejection of liquid;

- ease of carrying and using the equipment;

- ease of repair;

- use in different areas of the site;

- efficiency and functionality of devices.

Manufacturers rating

Popular brands are Marolex, Gardena, Grinda, Rosinka, Beetle, Solo, Jacto, Forte.

Russian brands of sprayers are distinguished by their affordable pricing policy and product quality. Garden sprayers are available in various sizes, with additional accessories: pallets, necks, belts.

German brands Solo, Gardena have established themselves as manufacturers of quality devices for gardens and summer cottages. The company has been on the market for a long time, for example, the Solo company has been manufacturing equipment for over 70 years. The goods are sold at a reasonable price, made of high quality materials, and are easy to use.

Chinese companies Grinda, Forte produce affordable sprayers that are easy to maintain. All devices are assembled in China using German technology and are quality certified.

Polish campaign Marolex founded in 1987. Produces a wide range of certified products. Sprayers from hand-held to battery-powered, with tank volumes up to 20 liters. The booms are equipped with a contamination protection system, the tanks are hermetically sealed. The company provides a 5-year warranty for its products.

Brazilian firm Jacto is engaged in narrow-profile equipment for the garden. As with all brands, the equipment is made of high-quality materials, has a long service life, ease of repair and replacement of device parts.

According to user reviews, the most vulnerable part of any portable sprayer is the areas in which the belts are fixed. Metal nozzles do not require frequent replacement. Cheap plastic hand sprayers are prone to breakage in the trigger area.

Gardeners give preference to Russian brands of hand sprayers, and in the category of knapsack and motorized devices, German firms are in the lead.

How to choose and use?

Before buying equipment, you need to decide on the volume of the sprayer reservoir and the type of work to be done.

Taking these factors into account, a number of characteristics should be guided by.

- The volume of the tank should correspond to the area of the treated area in one pass. Tanks up to 14 liters are used in areas up to 15 acres, up to 25 liters - when processing farms and large plots, 2-5 liters - for small areas or surfaces.

- The material from which the pump is made. The metal model is more reliable than the plastic model, but it is prone to corrosion. The average service life of any pump is from 5 to 10 years.

- The material from which the nozzle is made. They also come in plastic and metal.

- Spray. The main criterion is the length of the fishing rod; when processing hard-to-reach places or tall trees, it is advisable to purchase a sprayer with a telescopic fishing rod.

- The presence of a valve for releasing excess pressure.

- It is desirable that the plastic from which the reservoir is made is translucent or translucent to determine the amount of liquid. An additional plus will be the presence of a measuring scale.

- The quality and condition of the shoulder straps and their anchorages.

- Availability of sufficient spare parts for this sprayer in the event of breakdowns.

- Popularity of the brand.

- Instruction.

How to repair?

If the sprayer does not work, before starting the repair, you should carefully inspect the device and identify the cause of the breakdown.

The following elements are most often damaged:

- frame;

- hose;

- lever arm;

- clogged nozzle.

In case of mechanical damage to the tank or hose, it is enough to treat the cracked area with a sealant. A temporary patch can be applied to rubber hoses with a piece of rubber and special glue. However, it is recommended to replace the hoses with new ones.

The elements of the internal parts of the device corroded by chemistry are completely or partially replaced with new ones, they cannot be repaired.

The clogging of the nozzle is corrected by manual cleaning, blowing out the part and the outlet pipes.

For any kind of repair of a sprayer using chemicals and fertilizers, safety precautions must be observed!

It is not allowed to get the remaining liquid on the skin, mucous membranes, eyes. It is worth repairing the equipment with gloves, even if the unit has been thoroughly washed.

How to do it yourself?

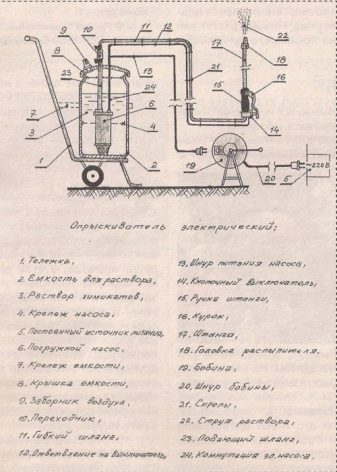

Making a homemade sprayer is easy if you have a diagram.

An important part of any type of device is the reservoir. A tank, plastic container, can is suitable as a container.

For a hand sprayer, it is worth using a compressor, a hose and a sprayer of any type, you can take it from a spray bottle.

For battery and motor you need a vibration pump, compressor, pump sprayer, hose, adapter and push button switch or lever.

The beginning of the assembly of any unit begins with drilling a hole in the selected tank and connecting the compressor using a nipple. All joints and fixings must be sealed with a sealant.

When assembling battery and other sprayers, a pump is placed inside the structure, the length of the tube should be to the very bottom. Holes are formed in the cover for hose, cable and air intake. The hose connects to the sprayer, on which the power button is installed. All cables supplying the pump are disconnected and routed outside the tank.

For information on how to make a sprayer for a garden and a vegetable garden yourself, see the video below.

The comment was sent successfully.