All about pressed sawdust

Pressed sawdust is a new eco-friendly material designed to take care of wildlife. Sawdust briquettes (or Eurowood) are currently used quite widely. Such materials are manufactured using a special technology and are subdivided into several types. In this article, we will learn all about pressed sawdust.

Description and production technology

Currently, the list of new and environmentally friendly materials is constantly updated with new items. These include pressed sawdust, which is otherwise called eurowood. They are made in the form of special briquettes. The very technological process for the production of such briquettes is based on one important feature. The latter is that the sawdust, after squeezing, always emit a special substance - lignin. This substance is a mixture of aromatic polymers.

Lignin can effectively glue together absolutely all sawdust particles, transforming them into a fairly strong monolithic product. The methods by which pressed sawdust briquettes are made are different. Such products are made both on an industrial scale and on a more modest scale.

Based on the specific manufacturing method, the moisture content of finished products can be from 6 to 12%, and the permissible pressure indicators are in the range of 300-1000 kg / sq. cm.

Due to such requirements, the independent production of pressed sawdust may require the master to resort to all sorts of tricks. For example, lignin is often substituted for other astringent substances. The following compounds have similar properties:

- wallpaper glue solution;

- clay;

- manure.

The materials in question are also manufactured on an industrial scale. Here, the production technology is in many ways different from homemade products.

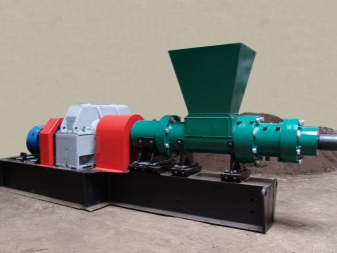

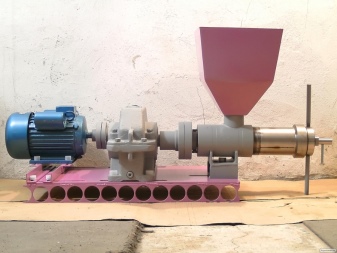

Experienced producers can use special professional equipment to quickly and efficiently compress sawdust.

The sawdust is always carefully sorted beforehand. Thus, it is possible to avoid getting into the press and finished briquettes of low-quality wood components. After that, the workpieces are thoroughly dried using a special machine. Thus, the sawdust is brought to the desired degree of moisture.

Due to the effect of high pressure, briquettes made of sawdust are heated to very high values (several hundred degrees). As a result, the outer part of the workpieces begins to slightly char. This is one of the striking indicators of the fact that Eurowood is made according to all the rules.

Sometimes, after the pressing stage, the workpieces are redirected to a special furnace. This is done for additional heat treatment of materials. Due to this procedure, the calorific value of the products for heating increases.

In order for the mass collected from sawdust to acquire the desired shape, professional hydraulic presses are used. They cannot boast of great performance, as well as the auger apparatus. However, hydraulic presses have one major advantage - they are capable of producing several wood briquettes at once. Besides, These devices can produce euro wood having a rectangular shape.

In the production of briquettes from pressed sawdust, special impact presses are very often used. True, such equipment turns out to be less effective, and in operation it is more complicated. Striking technique is completely unsuitable when it comes to the operation of automatic or semi-automatic lines.

Species overview

Various products are made from pressed sawdust. Consider what varieties this popular material is subdivided into. So, fuel briquettes, which are produced from pressed sawdust, are divided in accordance with their shape and size. The following types of material are found.

- RUF. This designation belongs to rectangular specimens with dimensional parameters 15x9.5x6.5 cm. Such products are made from natural wood sawdust with the introduction of specialized additives.

- Netro. Outwardly, such briquettes look like cylinders with a diameter of 6 to 9 cm. The length of these materials ranges from 5 to 35 cm. There are no holes in them. The products under consideration are based on compressed wood pulp. It is dried properly, then placed in a special loading tank. After that, with the help of a screw, the workpieces are sent to the pressing procedure. The raw materials are distributed into individual forms by means of dispensers.

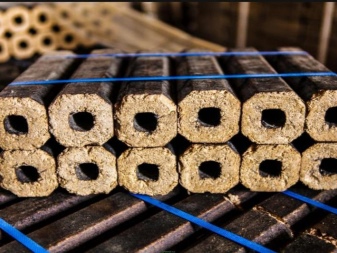

- Pini Kay. This type of material has the shape of a polyhedron. The total number of faces can be from 4 to 6. These briquettes are produced under the condition of processing at very high temperatures. Pressing here is also provided for quite powerful - up to 1100 bar.

Due to the fact that briquettes made of pressed sawdust differ in shape and size, it is possible to choose the optimal specimens for any firebox.

How to calculate the required amount?

Knowing the exact parameters of the calorific value, as well as the efficiency of the furnace or boiler, it will be possible to correctly calculate the required mass of wood fuel for a specific period without any problems. Wood briquettes pressed using a special technology, as a rule, are sold either by weight or by volume. If we are talking about the second case, then here you need to take into account some important nuances that are directly related to the structure of the products.

To accurately calculate the optimal amount of fuel, you will need to determine the mass of one cubic meter of material.

For such purposes, you can use one simple calculation formula. It provides for the following sequence of actions:

- first you need to know exactly the density level of the compressed environmentally friendly raw materials (q);

- then you need to calculate the filling factor (k) of the volume of the cube with sawdust;

- after that, the mass (m) of one cubic meter is easily calculated using the following formula: m = k * q * 103.

How to use?

Currently, sawdust processed by a press is one of the most demanded materials. They are bought or prepared at home for a variety of purposes. So, sawdust briquettes are allowed to operate as follows.

- If you need to light up a simple stove or fireplace in your home, then briquettes will be an excellent solution. Using them for such purposes is extremely simple. It is necessary to act here in the same way as with ordinary firewood. In a brick stove or fireplace, the heating period should take no more than 2 hours. If you do not keep track of this, then the masonry can gradually begin to collapse, so it is better to remain vigilant.

- If briquettes are used for the firebox, which are based on sawdust from coniferous trees or components with bark, then the owners will need to clean the chimney with great frequency. On its walls, special volatile compounds, which are formed due to the large amount of resins in the material, will necessarily be deposited. During the period of smoldering, the combustion time of sawdust will be more impressive than in the case of firewood. One bookmark will be enough for the whole night.However, the chimney will clog up at a high rate. Experts recommend carrying out a major cleaning at least 2 times a year.

How to do it yourself?

It has already been said above that it is quite possible to produce heating blanks from pressed sawdust at home. Manufacturing quality briquettes is not as difficult as it might seem. The main thing is to act strictly according to the instructions.

Preparation

To make good briquettes from sawdust, you need to proceed strictly in stages. Allow enough time for preparatory work first. First, the user will need to choose the ideal, high-quality material. For such purposes, the following may be suitable:

- ordinary sawdust;

- shavings that remain after processing various crops;

- waste paper;

- straw;

- recyclable materials left over from peat or coal.

The total share of shavings in the case of choosing a combined composition must be at least 60%. Only if this rule is observed can one expect good combustion quality from the resulting briquettes. At the preparatory stage, a person needs to stock up on the necessary equipment for pressing raw materials. Installations with the help of which it will be possible to compress sawdust are divided into several types:

- manual;

- which are based on a jack;

- hydraulic.

To obtain a sufficient production of lignin, it is permissible to use devices powered by a hoist. However, such solutions are not very efficient. In addition to the jack, which will play the role of a press, a special matrix and punch should also be used in the machine. It is these components that will give the wood a specific shape.

A self-constructed screw extruder will greatly simplify the task of creating a compressed fuel, but it is also more difficult to build it. For the production of the necessary materials, it is possible to use stationary equipment. It is also easy to build it with your own hands. For such work, you will need the following parts and components:

- bearings;

- motor;

- reducer;

- shaft;

- screw;

- heating elements - heating elements;

- relay to be able to regulate the temperature values.

If the voltage is three-phase, then a 9 kW motor is suitable. If the work is carried out from a standard 220 V network, then a unit with a capacity of 2.5 kW will be needed. This component, together with the gearbox and other assemblies, will need to be securely attached to the pre-welded frame.

In this installation, the auger is a special design, which consists of 2 main elements. One of them will act as a punch. The other component will send the sawdust to the tank for loading. The matrix can be successfully replaced by a profile pipe.

Before starting such a homemade machine, the pipe will need to be thoroughly warmed up to a temperature of 260 degrees Celsius. The heating element heating process can be controlled thanks to the relay.

Such designs have one drawback - an impressive coefficient of heat transfer directly to the air.

Manufacturing scheme

After all the preparatory measures and the construction of suitable home equipment, you can safely proceed to the production of the planned materials. The whole process consists of several stages:

- first, the selected raw materials are prepared and thoroughly cleaned;

- then the sawdust is thoroughly crushed to a permissible caliber of at least 0.6 cm;

- after that, the material must be pressed correctly;

- drying is the next step;

- the final step is the storage of materials.

When the shavings go through absolutely all the necessary preparatory stages, they are thoroughly mixed with clay powder in a ratio of 10: 1. Next, the resulting composition is meticulously mixed, while adding a little water.

The mixture should have a medium level of consistency so that it can hold its shape.

The learned and well-mixed mixture is carefully placed in a special compartment to make further briquetting. After this step, the craftsman will have to dry the firewood thoroughly. It will be possible to artificially increase the degree of flammability by adding cardboard to the clay, previously soaked in liquid.

Useful Tips

Let's take a look at a few tips for operating and creating compressed sawdust products.

- Briquettes made from sawdust are allowed to be used in boilers and furnaces, where automatic fuel loading is provided.

- If it is necessary to increase the combustion force of sawdust briquettes, it is advisable to let in fresh air. The compressed raw material reacts particularly actively to these manipulations.

- It is not forbidden to leave sawdust briquettes for storage indoors. These materials do not leave behind as much dirt and debris as ordinary firewood does.

- In winter, pressed raw materials can be stored under a shed. The main thing is to make sure that it does not come into contact with snow and moisture in general.

- If you made the equipment for making briquettes with your own hands, you must first make sure that it is working properly and only then proceed to creating homemade products.

- Some parts for assembling homemade equipment will have to be given for processing by a professional turner. Otherwise, incorrectly set clearances will not allow good production results.

- As a source of pressure when pressing wood raw materials, it is allowed to use almost any model of jacks. The main thing is that they can create the necessary effort - that will be enough.

How to make pressed sawdust, see the next video.

The comment was sent successfully.