Features of PVC Formwork Tubes

Today in the construction business there are no trifles. Sometimes the smallest part performs important functions, increasing productivity and business value of the work. A polyvinyl chloride (PVC) tube for a formwork system can be classified as such. It provides protection, preventing the contact of fasteners with concrete mortar, as a result of which the safety of the shields with components is ensured, and at the same time the costs of the construction of structures are reduced.

Description

The screed safety tube is a PVC formwork tube with stoppers at the ends. Used when pouring vertical structures (for example, walls, columns, pillar foundations, etc.).

Due to the structure of the retainer, a tight abutment of the tube surface to the formwork surface is guaranteed, which prevents the penetration of the concrete mixture inside.

If the shields are not fixed, then after filling the form with a mixture, they are able to creep along the sides, and even minor discrepancies in the structural dimensions reduce the quality of the finished monolithic structure.

If you install the bolts without additional protection, then they will remain "walled up" in a reinforced concrete or concrete structure. Therefore, to mount the next formwork, you will have to buy new screeds, and this, taking into account their price, becomes unacceptable from a financial point of view.

The parameters of the PVC tube for the formwork system are determined by GOST, and the choice of its size depends on the size of the cast structure. The standard is a tube length of 3,000 mm, an outer diameter of 25 mm, and an inner diameter of 22 mm. They are sold in packages, there are 40 pieces in one pack.

However, tubes with a diameter of 22 mm may not always be used. So, when there is a need to practice reinforced or thinner tie bolts. In construction, polyvinyl chloride products with diameters of 16, 20, 25, 32, 40, 50, 63 mm are used.

Primary requirements

Let's list the main consumer requirements of the tubes under consideration:

- high strength, otherwise the element will not withstand the pressure exerted by the poured concrete mixture;

- ease of processing;

- resistance to aggressive influences from the outside;

- compliance with the size.

The color should correspond to the color of the concrete solution, however, the regulations provide for the possibility of using additives for painting.

In accordance with regulatory documents, there may be removable stains or layering on the surface, as well as smudges typical for plastic products, provoked by a chemical-technological process. The material should not have obvious damage in the form of spalls, cracks, roughness, empty cavities or swelling, the presence of visually detectable foreign inclusions is unacceptable.

If necessary, various - technology-acceptable - changes can be made to the color, diameter and length, only this will increase the price for them.

Installation tips

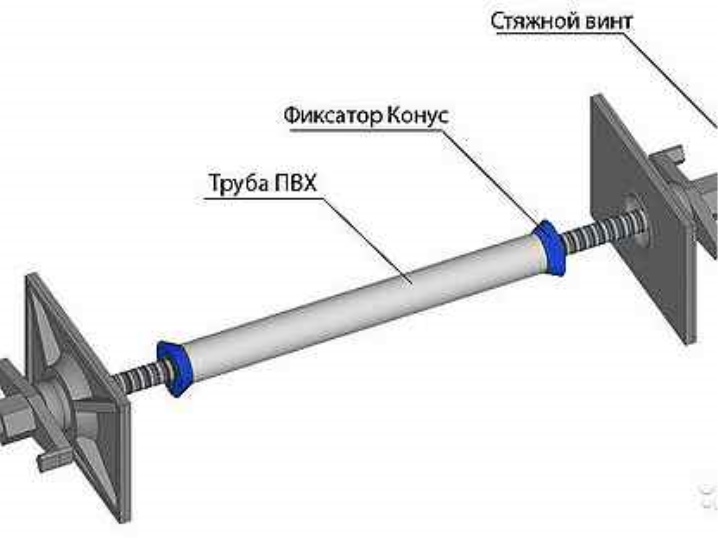

To install a tightening device, you need to have a set of the following elements:

- a tie bolt having a length significantly exceeding the thickness of the structure to be poured;

- 2 flat nuts;

- 2 wide washers;

- a polyvinyl chloride tube, the diameter of which is slightly larger than that of the clamping screw;

- 2 cone-shaped stoppers, they are mounted on the outer parts of the tube in order to prevent the penetration of the concrete solution inside.

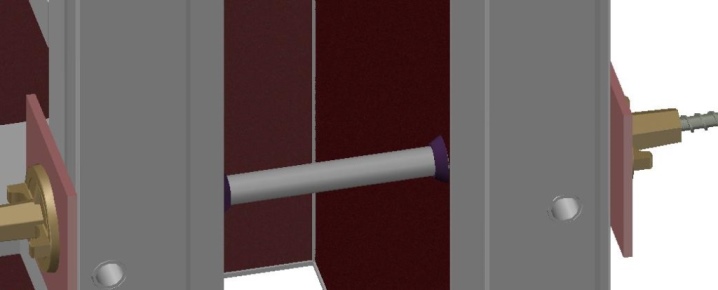

Installation is carried out as follows:

- a tie bolt is placed in the assembly hole of one of the formwork panels;

- a washer is put on it from the outside and a nut is screwed on;

- from the inside, a safety kit is put on in the following order: stopper, PVC tube, stopper;

- the unoccupied part of the bolt is removed through the assembly hole of another shield, a washer is put on it and the nuts are screwed on;

- the nuts are tightened in the required position.

When dismantling, nuts and washers are removed from 2 sides, after which the bolt is pulled out of the tube. The plastic elements themselves remain in the body of the monolithic structure.

Storage and transportation

Taking into account the technological features of the products, strict requirements are imposed on storage conditions. The permissible residence time of PVC pipes in the open air is six months. Placement under a canopy without access to ultraviolet radiation is possible within 12 months from the date of manufacture. During storage with transportation, products should be placed horizontally on a completely flat surface. To prevent mechanical damage and additional material consumption, loading and unloading operations are carried out using textile slings.

It is strictly forbidden to drag packages by dragging them along the ground.

The comment was sent successfully.