Everything you need to know about formwork

The article contains everything you need to know about formwork, what it is, and what you need it for. Formwork sliding on concrete, other types of formwork, formwork systems made of OSB and plywood in construction deserve a separate discussion. The principles of good calculation are also worth emphasizing.

What it is?

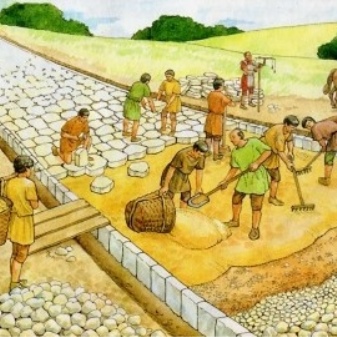

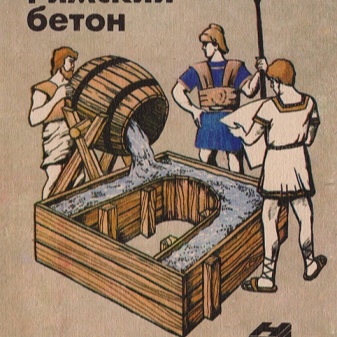

There are many different terms and definitions in construction. It is, indeed, a complex and ramified field of activity. But still, in most cases, capital buildings, including houses, are erected by pouring various solutions and / or laying blocks. That is why there is a need for formwork. It is known that for the first time such a product began to be used in the ancient Roman period, when concrete construction began.

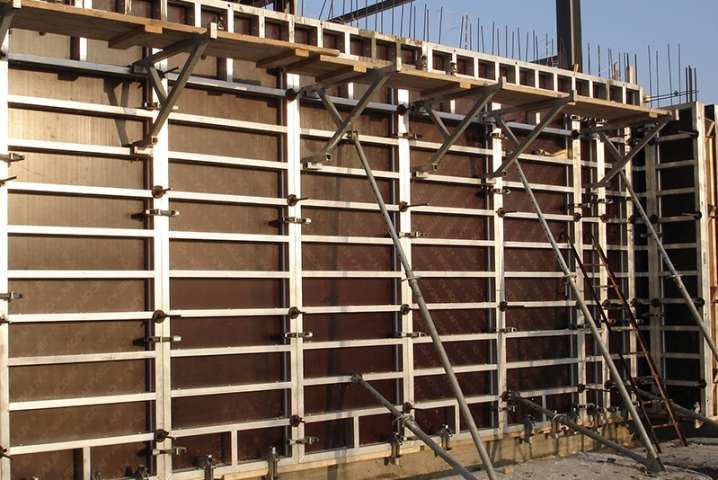

The formwork is the contour when pouring. Without a special barrier, it is impossible to give a liquid mixture clear forms, or even just keep it in a confined space. Traditionally, formwork was made of wood. But now other modern materials are also used for it.

The variety of fields of application necessitates the use of different types of formwork structures.

Primary requirements

Key standards are indicated in the thematic GOST 34329, introduced into circulation in 2017. The standard is declared suitable for all types of monolithic concrete and reinforced concrete structures. There are three main quality levels, with which compliance is very rigorous. Standardized:

- deviations in linear dimensions;

- differences on surfaces forming forms;

- violations of the straightness of the main parts of the formwork;

- differences in the length of the diagonals;

- number of protrusions per square meter (maximum);

- the height of the depressions on the main planes of the structure.

Of course, the provisions of the standards regarding probable defects are not limited to the matter. The strength of such structures plays a very important role. The stronger they are, the more reliable, and therefore, better perform their task, all other things being equal. Another important practical nuance is ease of assembly and disassembly. Ease of use at a construction site depends on this indicator.

Additionally, they evaluate:

- density (absence of any cracks and unplanned excavations not provided for by the project);

- compliance of the sizes with the necessary requirements;

- the level of standardization (typing) that affects the reusability;

- smoothness of the internal volume (any roughness is contraindicated there);

- the need for fasteners (the less it is, of course, the more practical the product).

The resistance of the load envisaged by the project must be at least 8000 Pa. It should also include resistance to the mass of the solution being poured. The vertical deflection should not be more than 1/400, and horizontally the requirement bar is slightly softer - 1/500.

For small-panel formwork, weight is 1 sq. m is limited to 30 kg. If this requirement is met, installation is possible without connecting additional mechanisms.

Description of species

Formwork is classified according to several criteria.

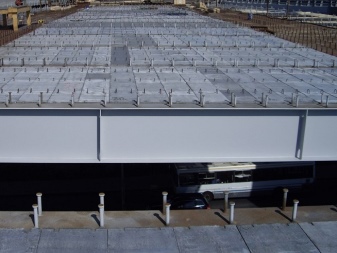

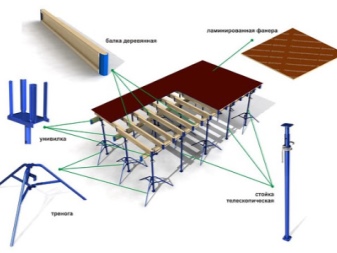

By appointment

Quite often, construction formwork for concrete is intended for overlapping in various buildings. A monolithic structure is always mechanically loaded, and overall reliability directly depends on its characteristics.Such parts are necessarily divided into several blocks, each of which has its own specific functions. Usually beams are made of wood or metal with different characteristics. Slab formwork for a slab of a house or a bath is formed according to a previously prepared sketch or even a drawing.

It is different:

- high installation speed;

- duration of use;

- ease of transportation to the desired point;

- suitability for use in complex configurations;

- possibility of installation without complicated lifting devices.

Higher demands are usually placed on industrial formwork. It is often used in high-rise buildings and must be quite sturdy. But at the same time, advanced manufacturers claim that their products are arranged very simply and logically. Everything is quite predictable here: the simpler this element is in appearance, the more convenient it is to use it, the less frequent errors, and the higher the result. It is recommended to contact firms with solid experience in special design.

But this does not mean that formwork is used only in capital construction. Often they take it for paths, for beds. Usually, these are special forms that it is enough to simply fill with one or another content, most often with a fine-grained stone or cement-sand mortar - and enjoy the result. The molds themselves look amazing and you can pour the mixture into them quickly and easily.

As a result, a path (ridge) is quite suitable for immediate use. The formwork for the pool deserves special attention. It is divided into stationary, which eventually turns into a part of the bowl, and adjustable, suitable for further use, types. The second option is preferable for professional builders. But it is easier to prepare the pool yourself with a non-removable formwork structure.

Of course, there is also a special formwork for posts and fences; but it must be borne in mind that some types can be intended for support pillars of the foundation, and they must have a naturally increased reliability.

If possible dismantling

Sliding formwork allows you to significantly increase the pace of the arrangement of buildings and structures. Reducing the time required increases the overall profitability of projects. Sliding formwork is used for both vertical and horizontal structures. The removable system (including the volumetric one) can be removed after reaching 50% of the strength specified by the standard. The number of fills is determined by the material; for handicrafts from 3 to 8 times, and for those made in factories - up to several hundred times, which is quite convenient, although relatively expensive.

Non-removable formwork structures are usually turned into part of the building foundation. And many years of operating experience show that this is a completely strong and sound solution. Many buildings with such a base stand confidently for decades without cracking. In addition, it can increase the operational properties of a building. Thus, a number of modern formwork materials guarantee excellent heat retention: this is exactly what extruded polystyrene foam is.

By the type of materials used

The substance used determines, among other things, the geometry of the formwork assemblies. It is far from always convenient to give a round shape, which creates additional restrictions. In many cases, OSB structures are used to surround concrete. It is applicable to both foundation supports and cast-in-place walls. Ease of processing makes it easy to get the required configuration. Oriented slabs are poorly saturated with water. Under normal operating conditions, dampness does not threaten them. Obtaining a one-piece shield without joint sections reduces the risk of concrete spilling out somewhere. As a result, the total costs are reduced. But many builders - both amateur and professional - willingly use plywood formwork.

The advantage of this solution is the comparative ease of assembly. But at the same time there is an important nuance, which is often forgotten - the assembly itself must still be carried out carefully. Contrary to the stereotype of plywood as something flimsy, it is relatively reliable and almost never fails. The service life is also quite decent, even against the background of other worked-out options. The surface of the material is relatively smooth. Wooden formwork is better than plywood in terms of strength indicators. Its service life is also attractive.

This option is often used when there is an acute shortage of time and money. Boards can be found at any construction site and will easily fit into even a meager budget.

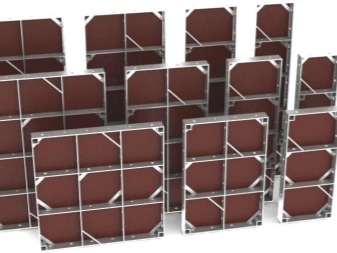

But you can't discount the foam solutions. They, as already mentioned, allow you to make the building warmer. This is extremely important in our country, like no other, and even more so beyond 45 degrees north latitude. It is curious that the formwork use of EPS came into Russian practice relatively recently, but abroad it has been practiced for at least 50 years. The bottom line is that a number of blocks are assembled from foam plastic, clearly divided into compartments and segments. In terms of the time and cost of living labor, polystyrene is quite economical. In terms of strength, there is no equal, of course, to metal formwork. This name most often hides stainless steel elements. They are quite convenient for arranging the foundations of buildings of various profiles and sizes. Compatibility with all soil types is fully guaranteed. The service life is at least not lower than that of blocks based on EPS.

In addition to steel, aluminum formwork is also in demand, which:

- easier;

- less susceptible to corrosion;

- universal;

- helps out in confined spaces;

- suitable for work on monolithic walls;

- and at the same time, unfortunately, is relatively expensive.

The main linear shields of aluminum can be at least 0.25 m wide. Other options are from 0.3 to 1.2 m; step of change - 0.1 m. The smallest recommended cross-section of aluminum profiles is 1.4 mm. The larger it is, the more reliable (but also more expensive) the design will be. Most often, the basis is extruded aluminum of the A-7 category.

Other parameters:

- tolerable pressure up to 80,000 Pa;

- turnover up to 300 times (sometimes less, depending on the type);

- the average weight of the aluminum shield is from 30 to 36 kg;

- span deflection level is maximum 0.25% of the length;

- the most common thickness is 1.8 mm.

Calculation features

The most important criterion is the number of formwork products to be delivered. Here you cannot limit yourself to simply determining the overall dimensions and subsequent calculations of the quantity. It is necessary to analyze what exactly is planned to be installed in one session. It is about the area being concreted at the same time. How many concrete walls and interfloor ceilings are poured at one time, the same amount of formwork should be - no more, no less; this allows you to make construction production more rhythmic.

Even a very experienced and well-equipped team with excellent motivation can fill no more than 140 cubic meters per shift. m of concrete. Usually, these indicators are lower, and depend, among other things, on the fatigue of the performers. Calculations for large buildings are based on specifications. They indicate in detail information about the arrangement of individual columns and other parts.

Not a single castable structure should be left unattended!

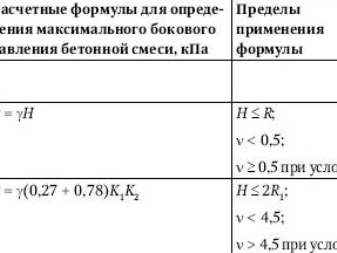

The smallest thickness of a board or other element can be calculated independently. Scheme:

- the square of the distance between the elements (in meters) is divided by the coefficient of mechanical resistance of the material;

- multiply the indicator by the correction index (depending on the method of squeezing concrete inside the molds);

- multiply again - now by the calculated pressure force;

- the resulting product is multiplied by 0.75, and the square root is taken from the final result.

What is needed for work?

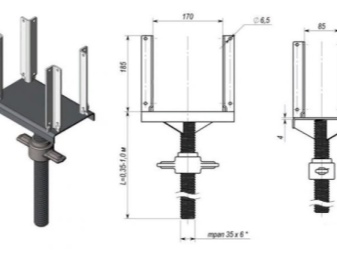

Among the formwork accessories, the unilk plays a special role. It is even included in official factory universal formwork kits. The main task of the unilk is mechanical support. With their help, they work on both vertical and overlapping slabs. These elements turn out to be the final part of the assembly kit.

A special two-level brace is designed to guarantee the spatial stability of the structure. In some cases, due to the brace elements, the shields are adjusted (set exactly according to the design values). There is a difference between single-tier and two-tier products. The girder is also the support of the formwork. It should be emphasized that, along with formwork, there are also frame girders, and they should not be confused categorically.

The crossbar solution guarantees:

- installation at any convenient point;

- bearing characteristic at the level of 8000 kg per 1 m2;

- minimal time consumption.

And also for normal formwork, nuts and clips are required. Another name for clips is a spring clip, which comprehensively explains their function and internal structure, the principle of operation. They are needed for steel, plastic and laminated plywood panels. But there are no trifles in construction, and therefore it is necessary to pay attention even to PVC pipes. Its task is to exclude the ingress of concrete mortar on those parts that may suffer from it; therefore, the screed of the shields can be performed without problems. Beams allow you to increase the stability of the fastening. These are I-beams made of wood. They are used for casting floors and other structures. Such products are easy to install. Spacers deserve a separate discussion. They are also sometimes called braces.

The distance between the stop points, excluding the creep of the formwork under the load of the overlying structures, should be a maximum of 1 m. Double-sided installation of thrust assemblies is needed in the corners where the load is greatest. A cone is another type of protective component that covers the free ends of the tubes. And when arranging floors, a telescopic rack is often needed. They have open or closed cuts. The rack includes a pair of pipes made of steel or aluminum. Closed type of cuts means covering with an external cylinder (casing). The length of the racks is at least 1.7 m, the maximum is 4.5 m.

Formwork system installation technology

The step-by-step instructions for making and fixing the formwork for the strip foundation with your own hands are relatively simple, if you look at the points. But you should definitely think about whether to turn to professionals. The probability of error is very high. The first step is to prepare the site:

- driving in stakes;

- stretching the threads;

- control of these threads or cords using a hydraulic level;

- digging a ditch (at least 0.5 m deep);

- maximum alignment of its bottom;

- the formation of the pillow.

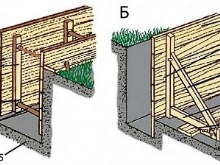

It is most simple and convenient to make wooden formwork on the basis of edged board or panel plywood. Be sure to seal all seams with a sealant. It can be replaced with polyurethane foam. First of all, the shields should be installed outside the trench and reinforced with diagonal elements. Such props do not have to be installed in 1 m increments; in difficult cases, you can bring them closer to 0.3 m. Then the jumpers of a given length are fastened with nails or other hardware (corners). In total, they should be no longer than the walls planned for the construction. Next, you should assemble the inner segment of the formwork. When this is done, check that all vertical and horizontal sections are correctly framed.

If mistakes are made, it is useful to disassemble and re-install the shields immediately - this will eliminate new problems in the future. Then you need to prepare and pour the concrete solution. For your information: so that after this procedure there are channels for technical communications, round metal sleeves are used. On the non-separable formwork, wooden planks are placed from the inside, to which reliable hooks are attached.Then they put several layers of roofing material or rubemast in order to completely exclude the release of concrete mass. The top of the material is folded over the wall and secured with special clamps.

Reinforcement

This procedure ensures resistance to temperature changes. Such protection is equally important for mountainous and coastal regions, for the Far East and the Far North. Monolithic strengthening of the formwork is recommended when arranging a reinforced concrete foundation. The rods can be connected using:

- knitting wire;

- welded seams;

- clamps (both vertical and transverse joining are allowed).

The dispersion scheme involves the use of fiberglass. In some cases, it is replaced with Kevlar. Finely dispersed additives guarantee not only mechanical strength, but also crack resistance. Modern construction often also involves the use of mesh hardening. The steel net is stronger than polymer and mixed composition, but it is prone to rust even with a carefully selected composition. The board formwork is pasted over with glassine from the inside before strengthening. The reinforcement itself is made using welded or knitted steel squares. The belt is required to be equipped around the entire perimeter.

This solution has proven itself from the best side. It can withstand all known types of mechanical stress.

Useful Tips

When the work on the formation of the slab formwork is underway, you can, again, use the removable and non-separable options. The choice of a particular type is largely a matter of personal taste. Recommendations:

- laying of plastic wrap will protect against leaks of concrete mix;

- when using wood for formwork, it is useful to additionally tighten the boards located on top with reinforcing wire;

- it is advisable to pour concrete in layers;

- when pouring the entire mass at the same time, care must be taken that the solution does not overflow outward;

- exclude excessively active treatment of the solution with vibration devices (if possible, it is replaced by manual bayonetting);

- disassemble the formwork from top to bottom (which eliminates the appearance of chips and cracked areas).

It is worth remembering about the key mistakes that can be made when forming the formwork. We are talking about:

- the use of low-quality wood, bad metal;

- the use of an inch board (it is difficult to strengthen it);

- insufficient deepening of vertical cross beams;

- excessively large or too small distance between the shield and the wall of the trench;

- leveling the surface by adding soil (it must be removed and removed, not added!);

- unevenness of the installed parts vertically and horizontally;

- lack of sealing wooden joints with tow.

In the next video, you will find a step-by-step installation of wooden formwork with loose slopes of the trench and a large difference in height on the building site.

The comment was sent successfully.