Universal ties for permanent formwork

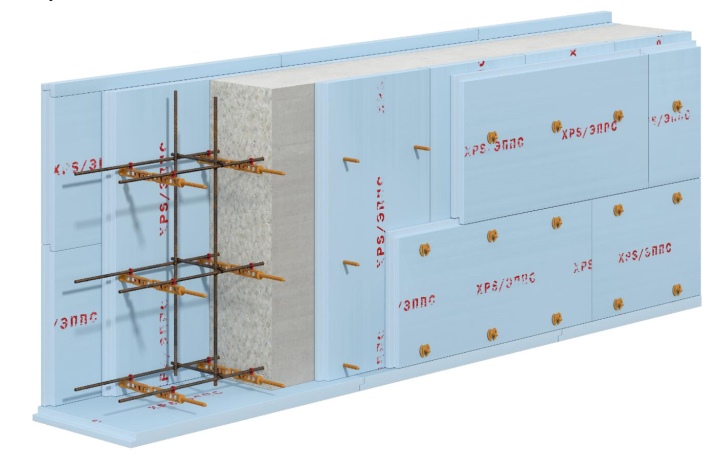

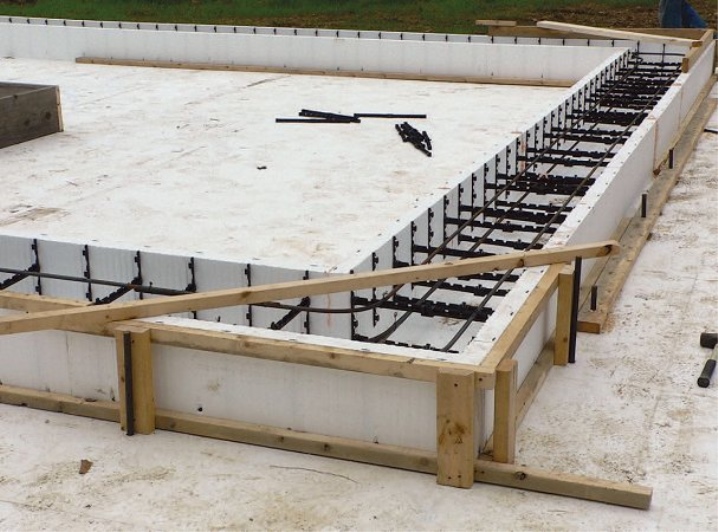

The impetus for the rapid development of the construction industry was the emergence of new modern equipment and innovative materials. So, thanks to the appearance of fixed formwork, one-story houses, garages, cottages, production facilities and indoor pools began to be built faster. Styrofoam blocks are installed directly on a reinforced concrete foundation, thus creating a single strong and reliable structure.

But how do the foundation and the fixed formwork fit together? For this, special universal ties are used. It is about this fastener that will be discussed in our article.

Advantages and disadvantages

A universal tie for permanent formwork is a special fastening system, with the help of which the formwork blocks are connected to each other and to other elements of the building or structure being erected. Most often it is used in the construction of monolithic buildings.

The universal screed is characterized by:

- high strength, precision and ease of assembly;

- low cost;

- incombustibility;

- frost resistance;

- impact resistance;

- long service life.

Its use in the construction process makes it possible to:

- install the fittings in the design position;

- reduce construction time;

- reduce material costs up to 30%;

- quickly and accurately complete the installation;

- reduce the cost of lifting mechanisms;

- reduce heat loss up to 17%;

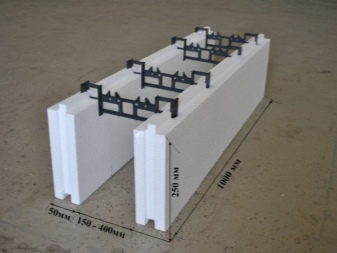

- fix formwork blocks with a width of 15 to 40 cm.

All of the above advantages have made universal screeds an indispensable fastening element for the installation of fixed formwork in low-rise monolithic construction.

What elements does it consist of?

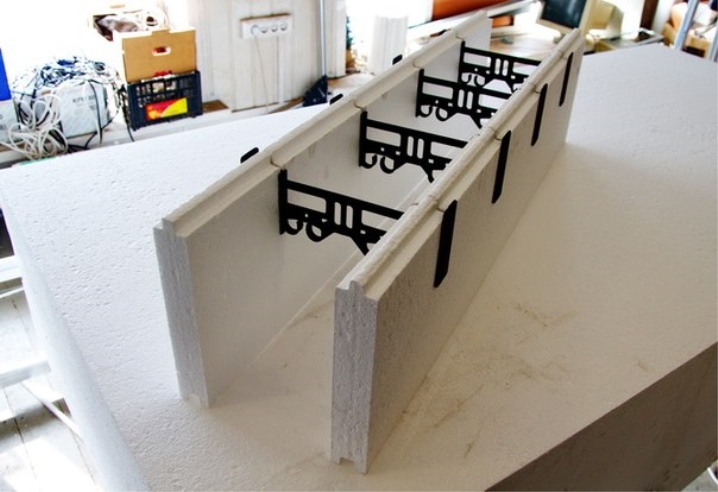

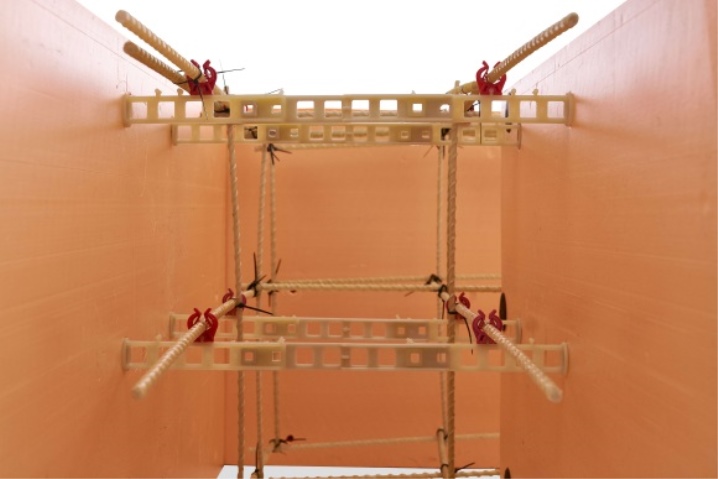

The universal tie is a system of polymer fasteners. It consists of reliable and durable parts.

- Screed - the main structural element.

- Retainer - an element that fixes sheet materials.

- Reinforcement clip. With the help of this element, the reinforcement is fixed in the design position.

- Extension. It is an adjustable modular element. The extension is used to adjust the thickness of the concrete part. Most often, an extension cord is not included in the kit, you need to buy it additionally.

Application area

The universal coupler is used in quite a variety of ways. Excellent physical and technical parameters make it possible to use it in various installation works:

- for fixing formwork blocks and foundations made of different materials;

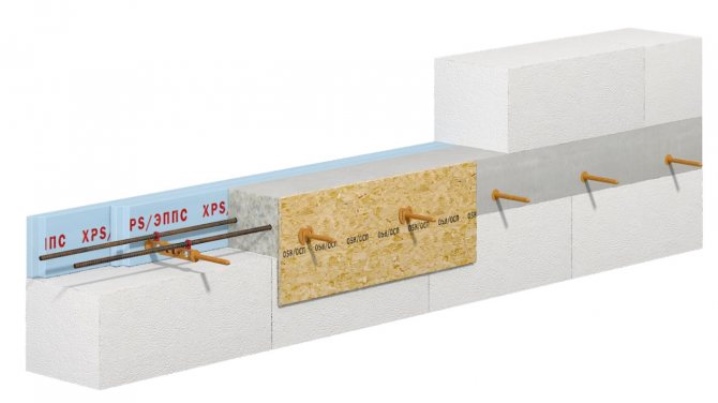

- lintels in the formwork over window and door openings;

- during the installation of strip and monolithic foundations;

- for fixing fixed formwork with walls made of EPS, OSB or facing bricks;

- during the installation of the armopoyas.

It makes it possible to fix blocks of permanent formwork with absolutely any material and structure, both during the construction process and at the time of concreting.

Fasteners are perfectly combined with all moisture-resistant materials such as plywood, sandwich panels, aerated concrete blocks, as well as fillers: crushed stone and expanded clay, wood concrete, polystyrene and foam concrete.

Manufacturers

Currently, there are universal screeds for permanent formwork from different companies on the market. But with such a large assortment, it is difficult to make the right choice in order to purchase high-quality and reliable fasteners.Models of both domestic and foreign manufacturers are presented on the construction market. A large number of universal ties are now shipped from China.

The leader in the production of universal screeds is the domestic company "TECHNONICOL". Its products are in the greatest demand, and all because they are of high quality, reliable, strong, durable. It is made exclusively from safe materials on modern equipment. All fasteners have international certificates.

In addition to the TECHNONICOL company, there are other manufacturers, for example, GC "Atlant", "PolyComposite". But no matter which manufacturer you prefer, be sure to make sure that the products are manufactured in accordance with GOST, are certified and have passed all tests provided by law and regulatory documents.

The comment was sent successfully.