Types and applications of plastic formwork

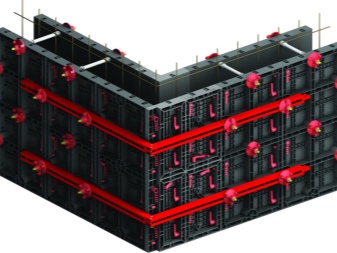

The modular formwork system is suitable for the construction of any kind of facility. Special shields help to create any required configurations. The article will focus on plastic formwork.

Advantages and disadvantages

Plastic formwork has a number of advantages:

- its versatility contributes to the embodiment of interesting design finds, since, in addition to vertical and horizontal fragments, there is the possibility of concreting curved elements;

- the relatively low weight of standardized parts against the background of metal counterparts makes it easy to assemble any configurations without using lifting equipment;

- durability allows long-term use of the structure, since it is not subject to corrosion, moisture, ultraviolet rays and temperature changes;

- excellent structural strength increases the resistance to pressure of the concrete mass;

- the use of a small amount of lubricant is achieved due to the fact that the interaction of the concrete mixture with the plastic does not occur - the form is easily removed from any surface;

- the high quality of the products made is associated with the smoothness of the panels, which ensure the evenness of the finished concrete;

- correct assembly guarantees perfect tightness of the joints and prevents leakage of concrete mortar;

- the ease of cleaning the surface after its removal is due to the absence of hardened concrete on it;

- in the production of plastic formwork, the reusable use of its removable options is provided;

- the speed of installation is ensured due to the versatility of the design, which allows you to quickly mount and remove the form;

- the dimensional accuracy of plastic products does not require adjustment during installation work;

- profitability lies in the possibility of using the labor force of one or two people, and the rejection of an entire construction team and the use of special equipment significantly reduces labor costs.

The disadvantages include the relatively low strength of the shields. when compared to their metal counterpart, and the need for preheating the structure in frosty weather.

Application

Formwork made of plastic material is used in the construction of objects for various purposes. It is ideal for monolithic construction. It is used to install walls, columns, ceilings and foundations.

The production of special sets designed for their concreting is well established.

The foundation frame is assembled with shields and then it is poured with concrete. The possibility of combining various fragments included in the kit allows you to assemble and cast load-bearing walls and all kinds of partitions of any size. Square, rectangular, oval and round columns are constructed using the supplied modules.

The formwork system is widely used for laying paths and paths in the garden, for creating concrete pools. The formation of modern landscape design is not complete without the use of plastic formwork.

Views

The classification of the complete set of plastic formwork modules is determined by a number of signs.

According to the scope of application, the following types are distinguished:

- universal kits used for the construction of foundations, wall panels, beams and various lintels;

- kits for the installation of various columns;

- modular structures designed for the manufacture of floors between floors;

- equipment for casting a curved surface, including flexible and radius fixtures.

By the nature of the dismantling, the division into two main types is known.

-

Non-removable the design assumes that at the end of the work it will remain an integral part of the building. The cellular structure helps to withstand heavy concrete mass. Such formwork is effective for monolithic wall construction. And also in great demand for laying the foundation. A plastic tie is well suited to this type of construction. It is she who allows you to combine plastic with plywood, slate, chipboard and other materials.

-

Removable plastic formwork blocks are widely used in construction. They are equipped with rotary handles that allow you to position the module parts in any direction. The versatility of this variety expands the scope. In the manufacture of removable panels, plywood is most often used. After the concrete has hardened, the removable mold is removed. In the future, it is used many times.

Installation technology

Installation of plastic formwork is carried out according to a certain scheme. She's pretty simple... First, you need to tidy up the construction site: clear the area, take out all the debris and level the surface. Then you need to prepare the structure itself, the inside of which should be well cleaned. The formwork must be installed evenly and efficiently so that later shrinkage does not provoke the curvature of the wall panels. Although plastic pieces are not prone to bending, it is possible to change the angle of inclination.

The disassembled formwork is mounted according to the scheme attached to it, providing for the assembly of the structure. It is carried out as a constructor for children. The shields are connected using metal fasteners. They are treated with a lubricant to create a sliding surface. It is very important to check the build quality. Then the frame is poured with concrete.

If the work is carried out in an open space at sub-zero temperatures, then preheating of the panels is required.

When making a monolithic foundation using fixed formwork, first, the base of the future building is laid out from special cubes. The structure is usually reinforced with fiberglass reinforcement. Then the intervals between the walls of the formwork are filled with concrete. The fill height should not be higher than one meter. The work is done in stages. If a removable form is used, then it is removed within a week. It depends on the strength of the concrete. It should be at least 70%. Then the space is cleared of concrete particles and other debris.

The comment was sent successfully.