Everything you need to know about fence formwork

A reliable fence needs a foundation. It is poured into a special frame (formwork), which gives the desired shape to the base. We will talk about what kind of formwork are, how to properly assemble and dismantle them after the concrete has hardened, in our article.

What is it and why is it needed?

After the construction of the house on the site, it becomes necessary to build a fence. The strip foundation, for which the formwork is made, presupposes a fairly powerful fencing of the territory with brick pillars or concrete blocks. For a fence made of corrugated board, too massive a foundation is not needed. The strength of the foundation is determined by the load that it will have to withstand.

Formwork is used for any strip foundation, in our case - for the construction of a fence. To make the structure strong and not fall from gusts of wind, it is installed on a concrete base. For the installation of the foundation, a trench is dug along the fence line.

Concrete poured without a frame will begin to soak into the soil and take on an irregular shape. Therefore, a formwork is installed in the trench, which can keep the cement mixture within its boundaries.

A frame is made of boards or wooden boards. Thin versions can deform under the pressure of concrete. To avoid this, choose durable products or replace wood with other types of materials. The formwork is taken out 25-30 cm above the ground. The foundation is raised to this level in order to avoid the impact of the soil directly on the material from which the fence was made. Wood in the places of connection with the ground decays over time, iron corrodes. The foundation protruding above the soil looks aesthetically more pleasant than the squat version.

The following requirements are imposed on the formwork.

- The presence of even corners.

- The walls should be free from deformation and deflection.

- The material must be rigid enough to ensure that the concrete is held in place without disturbing the formwork.

- Dismantling the frame shouldn't be a problem.

A properly executed structure is a guarantee of a high-quality foundation and a reliable fence.

Description of species

Formwork is erected when there is a need to pour in-situ concrete. It comes in different types.

- Horizontal. It is used for the construction of a wide foundation with concrete slabs. Metal fittings are installed inside the structure.

- Vertical. They are used for pillars, non-standard buildings, narrow fences.

- Oblique or architectural. They are mounted for a fence with a unique design.

In addition, the formwork is divided according to the method of their assembly into two more types - removable and stationary.

Removable

This type of structure is disassembled after the concrete dries and is transferred to the next section of the fence or is used several more times for other buildings. Thanks to the removable structure, perfectly flat foundation surfaces are created. High-quality formwork should be easily disassembled so that dismantling does not entail the cost of leveling the erected base.

Fixed

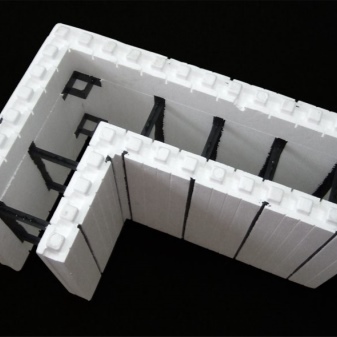

The stationary formwork is not disassembled, it remains part of the foundation structure. Performs an additional protective function, and with the right choice, also an aesthetic one.

Fixed structures are cheaper than removable ones, therefore they are more in demand.

Materials used

The walls of the formwork must withstand the resistance of the concrete and prevent deformation of the entire cast structure. For these purposes, the following types of artificial and natural materials are chosen.

- Wood. Formwork made of wooden planks belongs to the traditional types of structures that were used by our ancestors. The board is chosen inexpensive, but durable, such as pine or spruce. For demountable formwork, you can use old waste material.

- Metal. They are used in the form of sheets with a thickness of 2 mm in cases where the foundation needs to be rounded. The material is durable, reliable, and has good insulating properties. For the construction of formwork, it is rarely used due to the high cost of metal.

- Slate. To form a box for pouring a cement mixture, flat slate is used. It does not bend, has enough strength to withstand the pressure of small concrete volumes. But in the case of large-scale pouring, the walls of the structure may crack.

- Expanded polystyrene plates. They are lightweight, allowing them to be quickly assembled into a common structure. The formwork is not disassembled after the concrete has dried. It not only gives the base of the fence a perfectly even shape, but also is a good waterproofing protection.

- Reinforced concrete. The material has its own rigidity and adds strength to the potting compound. Thanks to reinforced concrete elements, cement is saved.

- Plywood. Only thick coniferous plywood sheets are used to create the formwork to hold the damp concrete. Better if they are laminated. Plywood panels are easy to assemble, but expensive.

- Chipboard. To neutralize the processes of swelling from moisture, laminated sheets are used for the construction. The formwork is assembled and dismantled quickly, but chipboard is not considered a good choice due to its instability to moisture.

The above list contains basic material. In addition to him, for the construction of the frame, you will need reinforcement and bars as spacers.

They will also help keep the posts upright. So that the workflow is not constantly interrupted in search of tools, they should be prepared in advance. For the construction of the formwork you will need:

- measuring instruments - tape measure and level;

- rope and pegs for marking on the ground;

- rammers to seal drainage;

- grinder, screwdriver;

- screws and nails;

- shovel, hammer.

Preparation

It is not necessary to involve specialists to install the formwork. If you have time and desire, you can do the installation yourself. Before starting construction, you should inspect the area on which the fence will rise. During the inspection, stumps, depressions, communication systems, and height differences can be found. Anything that is possible needs to be eliminated. In difficult situations, you will have to adjust the passage of the building bypassing the obstacle.

When the place for installing the fence is prepared, it is necessary to find out its dimensions in order to calculate the amount of material required for the construction of the formwork. At the next stage, using ropes and pegs, markings are made around the perimeter of the future fence. It is important to measure the corners correctly, take into account the location and length of the gate. Before digging a trench, the top layer of soil is removed.

The trench is dug in strict observance of the marking lines, the bottom is carefully leveled.

The size of the groove should be larger than the expected norms. For the width, a margin is needed to install the bars that hold the formwork walls. And the depth should correspond to the parameters of the foundation and cushion of sand, gravel and crushed stone.

Drainage will not only solve the problem with the outflow of water, but also become a support for the base of the formwork, give it stability. After filling a layer of sand, it must be poured with water and tamped, then lay out broken brick, gravel or crushed stone on top and tamp it again, leveling the bottom of the trench well.The dimensions of the recess can have parameters from 30 to 80 cm in depth and from 70 to 100 cm in width.

DIY construction stages

When the preparatory work is completed, you can start building the formwork.

Installation of the structure

To fill the trench tape with a frame, the following steps are performed step by step.

- If the structure is built of bars and boards, they are treated with technical oil or tar, creating a waterproofing layer.

- Along the entire perimeter of the trench, stakes with a section of 50x50 mm are driven in on both sides. The step between them is kept the same. Depending on the width of the ditch, the distance is chosen from 80 to 130 cm. The height of the beams should be higher than the future formwork walls.

- Shields or boards are attached to the exposed racks. To simplify dismantling, the heads of the nails should be on the outside of the structure. If the concrete is poured completely, the formwork is made solid. But you can divide it into sections of 4-8 meters.

- From the outside, the formwork is reinforced with jibs (bars with one-sided bevel). On one side, they are nailed to the middle of the flap, and on the other, they abut against the ground.

- The finished structure is reinforced with reinforcement or wire.

- The ends of the vertically installed stakes are interconnected with horizontal beams in order to strengthen the entire structure and prevent it from scattering under the onslaught of concrete.

- Metal brackets should be placed on the corners.

- When everything is ready, the gaps are carefully sealed to prevent the concrete from flowing.

- Polyethylene is laid inside the structure, which provides a waterproofing layer.

Pouring concrete

Do not make the solution too thin. Concrete is prepared at the rate of 250 ml of water per kilogram of dry mix. Excess moisture after drying can create voids in the cavity of the foundation. Lack of it will also affect the final quality of work. Other dry cement additives that absorb water are also taken into account. For example, when sand is added to the composition, liquid is added to it (4: 1).

Concrete is poured quickly, in full. If you have to divide it into portions, the filling time should be kept to a minimum. In addition, you will have to mix the mixture with a construction mixer for density and to avoid the appearance of air bubbles. After pouring the concrete, the foundation surface must be carefully leveled to create an even load on the soil.

With a flat surface, further construction work will proceed without problems.

Dismantling the formwork

When the concrete structure is completely frozen, it is necessary to free it from the restraining frame. The work is carried out carefully, slowly, so as not to damage the surface of the foundation. Sometimes dismantling can take several weeks. But the work on the construction of the fence can be continued, because the concrete is dry enough and has a branded strength. Stripping is carried out in compliance with the following steps.

- They begin to dismantle the structure from above, where the concrete sets faster. Remove edge and corner fasteners.

- Shields and racks are easy to disassemble. But you need to be careful to remove the material without damage. It can be reused.

- At the last stage, the support beams are dismantled, which receive the maximum load to hold the foundation.

If the dismantling was successful, the appearance of the foundation will be flawless, and the removed shields will be useful for the next work.

Helpful hints

Those who are first faced with the construction of formwork and pouring the foundation can take advantage of the advice of professional builders.

- OSB is the best option as formwork panels. They have good strength, flexibility, and are easy to cut into the required parts. The material is inexpensive.

- Work should not be carried out in hot weather, this will lead to rapid evaporation of moisture from the concrete. If there is no way out, you can use sawdust, cover unprotected surfaces with them.

- When assembling the formwork, it is necessary to ensure that there are no gaps between the trench and the bottom of the structure.

- In the places where the shields are connected to the pillars, the shields must remain inside the structure, and the pillars must remain outside.

- Fixing with self-tapping screws is performed at an angle of 45 degrees.

- Do not leave protruding nails inside the structure, this will complicate its disassembly after the concrete dries.

- You should not violate the stages of work or rush, because you need to make high-quality formwork, the strength, reliability and appearance of the foundation depend on it.

- If a non-removable device is used, at the end of the work, the basement of the fence should be refined. Decorative cladding with bricks, stones or tiles may be needed.

Removable formwork is more expensive but can be used multiple times. A cheap stationary structure requires improvement, you will have to spend money on cladding material.

The comment was sent successfully.