Formwork for monolithic construction

Formwork is the most important element in the construction of buildings or any other concrete structures... The reliability, safety and durability of the building will depend on the correctness of its assembly and the quality of the materials of manufacture. Therefore, before starting work, it is very important to study what kind of formwork is for monolithic construction, and what are its features.

What is it and where is it applied?

Formwork for monolithic construction is a special prefabricated structure in which liquid concrete, when solidified, takes the necessary forms. Formwork usually consists of several separate parts. Assembled structures are of two types:

-

removable;

-

non-removable or stationary.

The first type is assembled at a construction site immediately before pouring the concrete mixture, and after it has solidified, it is dismantled. With the help of removable formwork, all kinds of structural elements are created, both simple and complex configuration, for example:

-

various building structures of the vertical type, which can serve as a foundation base, reinforced with a belt (under the Mauerlat), and also play the role of an external wall or an ordinary internal partition;

-

horizontal type structures to create floors between floors, roofs of buildings and structures, canopies, awnings;

-

devices, surfaces and planes, which need to be positioned at a certain angle (stairs, ramps for cars) - for this, special so-called crawling formwork systems are used;

-

round or tapered designs, eg columns or radial walls, wall partitions - special rounded removable formwork is used.

Fixed or stationary formwork systems are most often used for the construction of low-rise buildings and small individual building structures. The range of use of these systems is limited, but in cases where their use is possible, they help to significantly reduce labor costs and save money. After the concrete mixture has hardened and the finishing work is completed, such formwork is not dismantled. It remains in the structure of the manufactured structure and complements it - it increases strength, reliability, improves heat and sound insulation of the room.

Species overview

For the construction of objects and the creation of individual structures, various formwork systems are used. In addition to the above two criteria, they are also classified into several types depending on the shape, size, installation method and purpose.

Consider the main types of modern professional formwork for a monolith.

-

Small-shield Is a collapsible, adjustable-type structure, which consists of several separate elements. Each mounted element has an area of no more than 3 square meters, and weighs up to 50 kilograms. This system is universal, since, if necessary, it is possible to assemble building structures of various sizes and configurations from it in a short time. As a rule, a small-panel system is used for the construction of low-rise buildings and other objects of a small area.

-

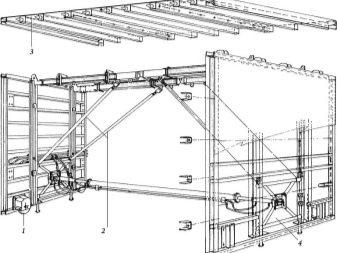

Large-panel the system is a collapsible structure consisting of large-area shields. In terms of size, each of these individual elements can completely duplicate the dimensions of entire walls, partitions or floors.It is mainly used for the construction of large-scale objects that need to be completed in a short time.

- Volume-adjustable the system consists of separate sections of extra large dimensions, pre-made in the shape of the letter "P" or "G" - these are the most common. For individual manufacturers, especially for custom-made, shapes and sizes may vary. To assemble the necessary structures, the sections are mounted using special equipment - lifting cranes, various manipulators. Due to the large size, the finished prefabricated structure is usually not poured all at once, but sequentially, in parts.

Complex volumetric-adjustable technology, in turn, is divided into several types, often used in large-scale construction projects. It is divided into horizontal, tunnel and movable-vertical.

It is important to note that when using a small-panel system, in most cases it is necessary to use additional supporting and supporting elements so that the assembled structure does not collapse under the pressure of the concrete mixture.

The formwork made of large panels can withstand significant weight loads even without additional support posts, because its design was originally designed for arranging foundations of a large area, long and high walls, and other massive objects.

The assembly of all these systems, provided that these are finished factory products, is not technically difficult - the kits are completed with standard elements and assembled according to the principle of a children's designer. The only difficulty can arise only on a large scale, when, for example, a lot of people or special equipment will be required to assemble a large-panel system when installing volume-adjustable elements.

Materials (edit)

Individual formwork elements for monolithic structures are either factory-made or self-produced. In both cases, they can be made from various materials - the main thing is that they meet certain standards and requirements.

The material for the manufacture of elements of the formwork system must have good bending resistance and a sufficient margin of safety, be inert to chemical compositions.

The material should not oxidize and react with the components and substances of the concrete mixture, so as not to violate its composition and not to reduce the reliability of the future structure. Self-supporting formwork for monolithic construction is most often made of wood or ordinary ferrous metal, factory structures are also made of aluminum or plastic. Let's take a closer look at each of the options.

Wood

Wooden structures are the most inexpensive, quickly manufactured and assembled, therefore they are often used for self-construction at home. Wooden systems assembled from boards or plywood can withstand about 25-30 cycles, therefore they are excellent for the construction of small buildings. However, they have low strength and hygroscopicity.

Steel

Steel formwork elements are considered the most durable and reliable, builders also mark them high versatility and durability. One design, with proper care and careful handling, can be used up to 500 times. The only drawback of such systems is the large weight of each element.

Aluminum

Aluminum structures are relatively light, but at the same time differ good strength - the cycle of use of one system can be up to 300 times. They are convenient in installation and transportation, but their significant disadvantage is that after frequent contact with the concrete mixture, corrosion begins to form on the surface.

Plastic

Plastic is the easiest and most convenient material to install for the manufacture of formwork structures. It is not affected by moisture and has a smooth surface, and the walls of hardened concrete also turn out to be smooth and beautiful.Due to this, subsequent finishing work in some cases can be omitted.

Plastic can withstand no more than 200 cycles, but despite this it has high strength, it is often used even in the construction of multi-storey buildings.

Dimensions and weight

The exact dimensions and weight of the structure will depend on the type of formwork, scale and area of the future construction. For example, a wooden system is assembled from boards up to 3 centimeters thick and 200 to 300 millimeters wide, the size of the boards is determined by the dimensions of the future structure, but in any case, you need to make a stock of 10-15 centimeters in height.

For steel systems, panels with a length of 0.5 to 2.5 meters are used, while their height should not exceed 3.5 meters, the approximate weight of one steel panel for formwork is 50-55 kilograms. Factory panels made of plywood are made weighing from 15 to 70 kilograms, and their dimensions range from 0.3x0.9 meters to 1.2x1.5 meters.

Popular manufacturers

Helios is a Russian manufacturer of aluminum and steel systems. Has been working in the domestic and world markets since the beginning of 2006. Produces strong and durable boards up to 3 meters high and 0.2 to 1.5 meters wide. Products are used both in civil and industrial construction when creating structures of varying complexity.

Kumkang - Korean company for the production of small-panel formwork. The systems are used in the construction of low-rise buildings, low-rise structures, as well as in the construction of private houses and auxiliary facilities.

Peri Is a German manufacturer of large-panel formwork structures. The systems are completed with straight and angular elements and are often used in the construction of various industrial complexes and facilities. They are distinguished by reliable locking mechanisms and brackets.

Installation tips

The assembly of each reinforced concrete structure must be carried out in accordance with the flow charts developed for a specific system. The cards describe in detail the order of work and the necessary conditions, as well as all practical requirements. But there are general recommendations that should be followed when assembling any structure.

The procedure for performing formwork during the construction of buildings:

-

prepare the site - level the surface, clean it of debris;

-

put up shields first internally, and then along the outer contour (installation should start from the corner);

-

support the shields from the outside factory or home-made stops, and from the inside to connect them to each other with special fasteners;

-

check the assembled system for leaks, if necessary, seal the joints;

-

if possible, apply a special substance to the inner surface of the shields, prevents the adhesion of concrete - this will help to extend the life of the system;

-

when creating a foundation slab, it is recommended from the inside, close the shields with a film or roofing material, by gluing them with reinforcing adhesive tape to avoid leakage of liquid concrete.

Dismantling of the system is carried out only after the concrete mixture has completely solidified, the period will depend on the volume, complexity and size of the structure. Disassembly is carried out in the reverse order.

After dismantling, it is imperative to clean the shields from concrete residues, especially aluminum and plastic ones.

Next, how to put the formwork for a monolithic floor in a house made of aerated concrete.

The comment was sent successfully.