Column formwork

Columns are of great importance in architecture. They are erected both in large, high-rise buildings, and in not very large, private houses. Most often, these structures are made of concrete.

What it is?

The formwork is a kind of frame into which concrete is poured. It is needed to give it the desired shape. This is very important in the case of column formwork, because stability depends on its correct geometry. Formwork, as you might guess, is used not only for professional purposes. Every person who intends to place a column for himself on the site will surely collide with it. Such a device has long been present in the everyday life of builders, therefore today it is divided into several types and types. Each of them has its pros and cons and is great for use in the case for which it was created.

Formwork types

Depending on whether the formwork can be used again or not, two types are distinguished: disposable and reusable. Each of them is vertical, as they are used for pouring standing concrete structures.

Disposable

The essence of such an auxiliary construction is to use it once. Of course, this leads to various pros and cons of such a formwork. Its cost will be quite low when erecting a pair of columns. This is achieved by using simpler and, therefore, inexpensive materials. A huge plus is the storage and transportation conditions for formwork parts. They are stored in the form of materials that can be easily transported to any place where the construction is planned, and if it is necessary to postpone the date of the construction of the columns, they will not cause discomfort in storage areas, because they will not take up very much space.

This type is used mainly for pouring round monolithic columns. The point is that a circle is the simplest geometric shape. The materials from which the disposable formwork is made are sufficient to bend them into a circle. For more complex columns, stiffer and stronger materials will be required.

The disadvantages of this type are the rather high price with the frequent construction of columns. The price of one is very small, however, in the case of a wholesale purchase, the situation is completely different. Therefore, this type of formwork is perfect for private construction, where it is not required to erect a large number of columns. A subtype of one-time formwork is a non-removable type. It is used as a decorative element in an already finished column.

It is used extremely rarely, but it is quite appropriate when used correctly.

Reusable

Formwork of this type is distinguished by its relatively high price, however, it completely fights back when used for the purposes for which it was originally conceived - reusable erection of columns. Of course, the obvious advantage of this type is the savings in money, by making a larger payment initially for a smaller fee in the future. However, it will be beneficial for those who are professionally engaged in pouring columns.

The buyer of reusable formwork should understand that maintenance of such a structure is more difficult than a one-time formwork. So, reusable formwork is more difficult to transport from place to place, and to this is added the fact that it will constantly need to be stored somewhere. Despite the many inconveniences of this type, its huge advantage is the ability to fill columns of the most bizarre shapes. This is something that cannot be done with a disposable type.

It is appropriate even for pouring pipes under piles, which can be done with disposable formwork, but it will come out more expensive than with reusable formwork.

Materials (edit)

Formworks also differ in their materials of manufacture. Depending on what its parts will be made of, its properties and purpose will change.

Cardboard

This material is used for the manufacture of disposable formwork. Its simplicity makes it possible to achieve the minimum price for this type of product. Sometimes cardboard is replaced with special, impregnated paper. Both of them are easy enough to dismantle after the concrete has hardened. The disadvantage of paper formwork is that it will be problematic to build complex columns using cardboard, so it is better not to use it for such tasks.

Wooden

He is successfully practiced in private construction. It's all about the availability of materials - any not very large boards or ordinary plywood will do. It will not be difficult to knock together the shape of the fill. Moreover, the column can be made both round and with sharp edges in the form of a polygon. But taking into account the fact that this is still a tree, and not solid, but consisting of boards, then you will have to use some additional layer between the concrete and the formwork. For a construction company, this type of material is not suitable, as there will be difficulties in storing and transporting the components.

The erection of the structure is fast enough if one or two pieces are required, but in large quantities there will be problems with the waste of a large amount of time.

Metal

Indispensable in professional construction. Such formwork consists of separate components - panels, which are assembled at the construction site. When using the so-called universal shields, workers have a wide range of tasks, because the number of shields can be any, which means that the height of the column being erected can also be varied. This material allows you to erect tall and wide columns. However, it causes difficulties in the storage and transportation of parts.

Metal formwork is a reusable type, and due to its strength, it is capable of a long service life.

Plastic

This type, unlike metal structures, cannot withstand high pressure from the solution. Therefore, it is not used for casting large columns. But this material is very light, so it is easier to install. Also, in addition to polygonal column types, this formwork can be used to fill round and oval columns. It is mainly used for professional purposes in the construction of low-rise buildings. This leads to a low price for such products.

For large columns, this type is not suitable, since there is a possibility that the formwork simply will not withstand the pressure of concrete.

Combined

We can say that this type has its ancestor in the form of metal formwork. In fact, the composite structure also consists of steel or aluminum, but with the addition of wooden elements. Or, conversely, the holding elements can be made of wood, and their edges are made of metal. In general, combinations of various materials are made either in order to reduce the price of goods without lowering the quality, or to increase the reliability of the formwork without much increase in the price of it.

Dimensions (edit)

Concrete structures are of different sizes. For timber formwork, this is not a problem - just add more planks and increase the diameter of the product. But for metal and combined, this is an important point.If the shields are too small, then you won't be able to use them to create large and wide columns.

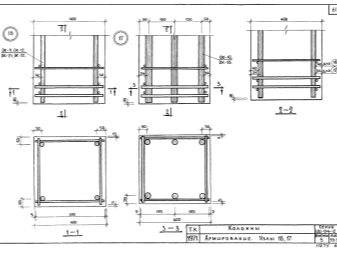

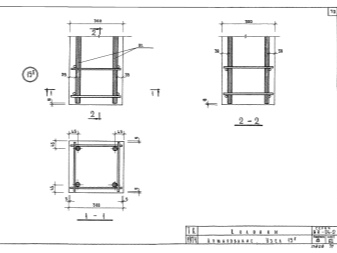

The size of the shields determines the largest area of the polygon that they can form. The most popular sizes are 300x300 and 400x400. The height depends either on the length of the boards or plastic in the case of the formwork of the same name, or on the number of panels in the case of metal formwork.

Mounting

The right formwork is the first step to good columns. To do it yourself or in an enterprise, you should follow a small and simple instruction. However, more accurate actions can only be taken on the basis of a plan or drawing. This is necessary in order for the end result to be worthy.

The very first thing to do is to place the formwork in the right place. If using universal shields, this will be slightly harder. First, the first guide parts are placed along the diameter of the future column. With the help of special tools - crossbars, braces, they are aligned. This action is performed with subsequent levels. You need to connect the shields to each other using special locks.

It is worth considering that when erecting tall structures, you will have to use scaffolding, and, if possible and necessary, a crane. After the formwork is installed, the stage of reinforcement introduction begins. Poles are inserted inside, which are designed to strengthen the future concrete. They are hammered into the ground to such a state in which they can stand all the time the column is being poured.

At the end of the installation of the formwork elements, the concrete mixture can be poured. When using shields, this task is simplified for tall columns. It is enough just to open the shield every time, which is at the required level, and pour concrete through it. It is not difficult to fill the formwork in this way.

Dismantling begins when all the concrete has hardened. To do this, you will need to remove the shields one by one, starting from the top. With any other formwork, this is easier to do, for example, in the case of a wooden structure, it is enough just to remove the boards that are part of it. Column formwork is an irreplaceable thing in construction. It exists in a variety of forms, which allows you to use a specific formwork for a specific task.

Its installation can be carried out by both a private person and a construction team.

You can find out how to make the formwork for columns with your own hands from the video below.

The comment was sent successfully.