Refractory materials for ovens

If you plan to build a stove or fireplace, you need to take care of safety and eliminate the risk of fire. This is easy to do, because there are refractories that sheathe walls around a dangerous object. It is much more profitable to acquire such materials than to rebuild a house or a bathhouse after a fire.

Description and purpose

Refractory materials (refractories) for furnaces are made from mineral raw materials and have the ability to retain their properties for a long time when heated, as well as when working in aggressive environments, without collapsing.

Refractory materials, due to their special properties, not only protect the premises from fire, but also prevent heat loss.

This led to their use for the construction of protective coatings during the construction of stoves and fireplaces in country houses, baths, premium apartments, as well as for fire protection of chimneys and surfaces around them.

Requirements

Refractory materials must reliably protect the home from any fires, without deformation, withstand numerous heating-cooling cycles for a long time, be environmentally inert so that no harmful substances get into the room when heated.

They must have:

- fire resistance sufficient to ensure safety;

- low thermal conductivity;

- constancy of shape and volume when heated;

- chemical resistance;

- slag resistance;

- low ability to absorb moisture;

- increased durability.

Species overview

Previously, asbestos or asbestos-containing sheet slabs were commonly used to decorate walls near stoves. But today, these products are not used in residential and industrial premises, because when heated strongly, asbestos releases carcinogenic substances that are harmful to people, and especially to small children.

Asbestos dust, which gets into the lungs and also causes serious illness, is also dangerous.

- Today, the best refractories for this purpose are considered fire resistant plasterboard panels... The maximum temperature of their application exceeds 1400 degrees. Fire resistance - up to 30 minutes of fire resistance; they do not light up for 1 hour, even if the fire has already started.

- Fiber cement minerite slabs multifunctional and environmentally friendly. They are made from cement - gray or white - with the addition of cellulose. They are characterized by high temperature resistance, strength and shock resistance, and work well in a humid atmosphere.

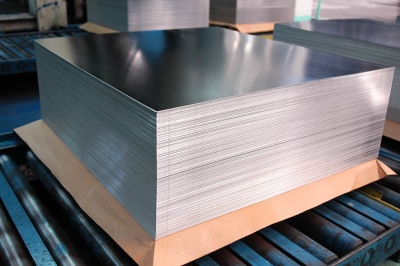

- Stainless or clad steel, Is a very popular, albeit expensive, material. Formally, steel does not belong to refractories, but it has the highest heat reflection coefficient in comparison with analogs and does not lose its properties due to temperature changes.

- Refractory made from basalt fiber (mats or rolls coated with aluminum), does not ignite or deform when heated to 900 ° C, it is also completely hygroscopic.

- Versatile, practical and durable superisole Is a special refractory (up to 1100 degrees) material. It is made from calcium silicate, which makes it environmentally friendly and has a low specific gravity.

- Porcelain stoneware or terracotta tiles - not only refractory, but also an excellent decorative material, chemically inert, environmentally friendly, vapor-proof and durable. Terracotta tiles have an increased ability to give off heat, while porcelain stoneware is resistant to cracking.

- Environmental requirements are also met xylene fiber refractory... It is produced in sheet form. The material is technologically advanced and moisture resistant.

- Widely used fireclay refractories have high heat resistance - up to 1300 ° C. This versatile material is also very beautiful, it looks like sandstone. The market offers different types of it - fireclay bricks, plaster, glue, mortar and mastic.

- Modern reliable fire retardant material - expanded vermiculite slabs, characterized by high - up to 800-900 degrees - heat resistance. They do not rot, are not susceptible to microbes, are not to the taste of rodents, and also comply with environmental requirements.

- Refractory slabs made of mullite-silica fiber have high chemical resistance to alkalis and acids. They have no analogues in their refractory properties.

- Glass magnesite Is a heat-resistant composite material based on magnesium chloride and oxide. It has increased moisture resistance, density and strength, is lightweight and easy to use. Magnesium glass sheets are often used as an alternative to fire resistant drywall.

The nuances of choice

A wide variety of species often makes you doubt the correctness of your choice. In order not to have problems and not have to regret the decision made, it is necessary to decide on the material that will protect the walls next to the stove, chimney or fireplace.

For wall decoration around stoves and boiler rooms

Fire retardant wall decoration around stoves and in boiler rooms is prescribed by fire safety regulations and is mandatory.

- Fire-resistant plasterboard panels can be used as the basis for wall cladding near the stove.

- Using fireclay bricks and / or mortar, they create a refractory shield in the form of a screen near the furnace. The surface inside the oven is laid out (lined) with a brick, and cracks and cracks are closed with a solution.

- But the most effective protection of surfaces adjacent to fireplaces and stoves, made of stainless steel. Steel sheets are used for the construction of fire protection screens. They are mounted at a distance of 1-5 cm from the body of the stove or fireplace.

- Fiberglass placed under the steel sheets allows to increase the thermal protection even more.

- Cast iron screens are also popular.

- Basalt rolls and mats, flexible and lightweight, are also used to shield stoves and fireplaces.

- For fire protection of boiler rooms, like baths, terracotta or porcelain stoneware tiles are ideal. They do not deform or burn, and they are also easy to maintain - they are easy to clean and wash. Due to their high decorative properties, they can also be used to decorate various surfaces.

For pipe

Chimney exit points must be reliably insulated to prevent fire. For this, mullite-silica slabs and cardboard are used, which are excellent for processing. Holes of any configuration can be cut in them for chimney pipes and other structural elements of furnaces.

For a bath

Bath walls are finished with heat-resistant materials so that they have refractory properties. To do this, use:

- "Pie" of a metallic reflective coating and a heat-insulating pad;

- superisole;

- fire-resistant drywall;

- glass magnesite;

- minerite;

- terracotta tiles.

Fire protection for the oven in the bath is also provided by products made of foamed vermiculite. For the interlayer between the first rows of the oven masonry and the wooden floor, vermiculite boards are preferable, since they are stronger than cardboard.

During the construction of furnaces, professional stove-makers traditionally use fireclay bricks that can withstand fairly high temperatures and sharp cooling.Modern material - lightweight refractory chamotte - perfectly absorbs mortars mixed with cement and clay.

For fireplace

The main tool used for facing the fireplace, along with fire-resistant plasterboard, is fire-resistant ceramics:

- terracotta tiles or majolica as its variety;

- tiles;

- clinker tiles;

- porcelain stoneware.

All of them are moisture resistant and resistant to temperature extremes. Look for A-labeled tiles - they are of higher quality than B-labeled tiles.

Installation tips

Minerite slabs can be fixed with screws; to increase reliability, use 2 plates. In this case, the minerite sheet should not adhere tightly to the insulated surface. An air gap is left as this material is subject to thermal deformation and increases in size. Alternatively, the minerite sheet is attached to a heat-resistant substrate, which increases the efficiency of thermal protection.

Steel plates inside the protective screen are joined with heat-resistant materials, for example, heat-resistant mastic, resistant at temperatures exceeding 1100 ° C, heat-resistant glue or sealant. On the market, along with side ones, they offer frontal protective screens. They are attached to the floor near the stove. Sometimes instead of metal screens, fireclay brick walls are built, which separate the furnace body from the space of the room.

Refractories in the form of plates and sheets are very technological for thermal insulation of premises. So, fireproof drywall is attached to screws or glue.

To work with fireclay bricks, solutions are used based on light clays with a small addition of sand. Fireclay clays are reliable and durable in use, they hold the masonry well together.

At the same time, professional stove-makers use special heat-resistant adhesives for laying fireclay refractories, which are characterized by low shrinkage and the formation of thin seams. All this also works to increase the strength and durability of the structure.

The comment was sent successfully.