Hydraulic shears: description, types and subtleties of use

Special equipment is required for any construction or dismantling of buildings and structures. If there are iron elements in the structure, then hydraulic shears are an indispensable device. The specificity of this type of equipment is different and depends on many characteristic features.

Peculiarities

Hydraulic shears are successful in cutting rebar, which is needed for concrete structures. Steel products will also not become an obstacle for this type of equipment. The technical structure of the hydraulic shear seems to be complicated, but in reality it is simple. The tool is popular not only in construction work, but also in industrial production.

The device has individual settings that suit the purpose of use. There are types equipped with automatic equipment for feeding the processed material.

The hydraulic cylinders are responsible for this setting. Because of them, automatic systems are usually very large. The length of the cutting edge of these types reaches eight or more meters.

If you don't need a large device, you can choose the option with manual control parameters. The scope of use of such equipment is already, but scissors can be used, for example, for cutting a cable. The force is transmitted to the object by pressure generated by an internal pump.

This built-in hydraulic system transmits a powerful enough force, making the task of cutting even thick cables much easier.

At the same time, hand tools are characterized by compact dimensions and increased mobility.

In the production of various materials, handheld shears with an external pump are used. The tool is suitable for cutting products with particularly large dimensions. Pressure is supplied to the tool through a long flexible tube. This distinctive feature allows you to place the separating part at absolutely any angle. Labor is also simplified due to the possibility of connecting any pumping device.

Both hand pumps and large stationary stations are combined with the scissors.

Working with metal is possible without a special separating device. One-time undercuts or cutting of thin rods are allowed with the help of a grinder. An electric jigsaw and conventional metal cutters are also suitable. We will talk about the scope of application of hydraulic shears and the principles of operation of the device further.

Principle of operation

The hydraulic shear system is similar in principle to variations of the manual or electric type. The difference is characterized by the way the force is applied to the separating element. Instead of a gearbox or manual mechanism, a hydraulic cylinder or pump plays this role. This design has many advantages.

- The high efficiency of conversion of efforts allows the development of a force for the blade equal to several tons. In this case, the dead weight of the tool varies from 1 to 4 kg.

- The mobility and autonomy of the device is higher in comparison with manual or electrical devices.

- The cut quality is better as the cut is longer.

- The hydraulic drive is safer than other options.

- The guillotine type of knives is considered to be an improvement over lever tools.

- The blade moves at a low speed, so the work process is easier to control.

These are the main advantages of a hydraulic tool. Fast and accurate work is essential when cutting sheet metal. This factor is especially relevant for detailed cutting of thick sheets.

Varieties

Regardless of the principle of work, the tools are divided into:

- knife;

- nibbling.

The first version of the product is equipped with two single-edged knives. Only the edges of the material to be cut can be cut with these scissors. The middle of the workpiece can be cut with punching (nibbling) shears.

The following types of hydraulic shears are known.

- Manual used for ropes and fittings. The tool has been successfully used in rescue operations. Scissors are used when cutting large quantities of rods and wires. The system of manual hydraulic shears is different in the design of the sharp part. Professional tools are guillotine and edging. If the first option can easily cope with bundles of wire and cables, then the second is useful in processing sheet metal.

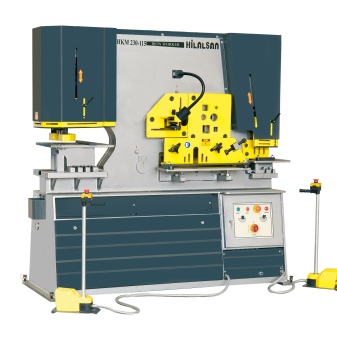

- Stationary hydraulic systems are connected to the pumping station. The tool can cut any metal products of different thicknesses. The tool is widely used in the automotive industry. Devices of this type (press-shears) differ in the most overall dimensions.

- At metallurgical complexes are used alligator or sorting shears. In these variations, the split part rotates relative to the handles, which makes the tool very practical to work with. Varieties of these models differ in the way pressure is applied. There are options with plunger pumps, and there are products with an external compressor station.

Selection recommendations

The performance and specifications of most hydraulic variations are versatile. When machining workpieces, it is important to consider the thickness of the material. The shape of the working part of the product is selected based on the scope of its use. When choosing, special attention must be paid to the dimensions and weight of the scissors themselves.

Hydraulic tools have basic operational parameters that you can rely on when choosing tools for cutting metal, rubber, concrete, tires:

- the maximum possible indicator of the cutting force, calculated in kN or tons;

- the gap between the cutting blades in mm;

- unclamping force, calculated in kN;

- tractive effort in kN;

- parameter of thrust movement in mm.

Combined scissors designed for opening structures are equipped with an additional pedal. It relieves pressure in the working pump. If the tool has been idle for a long time, this part may not work properly.

Working with this type of instrument should begin with a mandatory check of the pedal equipment.

Classic hydraulic shears can cut a profile with a cross section of about 100 mm. The tool is suitable not only for rolled metal, but can also be used as attachments to an excavator. There are firefighters or cable hydraulic shears, they are used by the corresponding services. A tool with knives, working like a guillotine, is needed to cut rebar, wire or cable. The cuts made with such products are of good quality, even if the cables are thick enough. These device options differ in the way the blades are closed.

Industrial scissors can handle materials up to 60 cm in length and 35 cm in height. The tool is connected to a platform that is driven by an electric motor with a power of 5 kW or more.

To choose scissors for your home, you need to consider:

- location of cutting edges;

- the shape of the blades;

- cutting feature of the tool;

- model power;

- convenience for use in a specific situation;

- the presence of basic protection.

For a single cut, it is not at all necessary to spend money on an expensive model.

User manual

Before using the product, you must follow a number of the following recommendations.

- Each tool comes complete with accompanying documentation, which must be studied in advance.

- Newer models usually have a protective lubricant that needs to be removed from the blades.

- The cylinder must be checked for oil level, and the entire pneumatic structure must be correctly combined into a single system. If there is no oil in the pump, it should be topped up using only suitable technical grades. Recommendations for the choice of lubricant are contained in the manufacturer's technical documentation.

If the lubricant is incorrectly selected, no one guarantees the performance of the tool. This can also result in a shorter lifespan of the hydraulic shears.

When using the product, you must adhere to the following rules:

- the standard characteristics of the tool must correspond to the thickness of the processed material or be more;

- replacement of lubricants in the pump should be done at least once a year;

- in the event of an emergency, cutting should be stopped immediately;

- most of the hydraulic type tools are subject to repair, after which their reuse is allowed.

To use conventional hydraulic shears, the worker does not need special training, he just needs to learn the specifics of the design.

It is also important to know the general safety rules. When using the tool, it is important to consider:

- the correct position of the tool, especially its working part;

- features of treatment with anti-corrosion compounds during long storage;

- mandatory cleaning of moving parts before starting work.

An overview of the model of the hydraulic shears for metal, see below.

The comment was sent successfully.