We make a trolley for a walk-behind tractor with our own hands

A trolley for a walk-behind tractor is an indispensable thing for owners of both large land holdings and modest gardens. Of course, you can buy it in almost any specialty store, but you can try to make it yourself.

Self-production

This device will simplify the processing of a summer cottage, and will also help to transport various goods, from hay and crops to the remaining garbage. Its production does not require expensive and complex materials, rather, most of them will be found in a home workshop. In this case, a home-made cart will be much more economical than a purchased one, because the latter will cost from 12 thousand rubles in the case of a new design and from 8 thousand when choosing a used one. The dimensions of the designed trailer depend on what kind of load it has to work with. For example, to transport 2.5 centners of cargo, the cart must have a width equal to 1150 millimeters, a length of 1500 millimeters and a height of 280 millimeters.

Preparation

When it is decided what parameters the planned cart corresponds to, it is worth making drawings, and then calculating the amount of material required, including the channel. Craftsmen recommend based on those details that are already at hand, and if necessary, buy something. The profile pipe of rectangular or square section can be easily replaced with the round one that is available. All detected parts must be cleaned of corrosion spots and covered with a rust converter with a priming function. In accordance with the drawings, some of them will have to be corrected by removing unnecessary elements. Then all that remains is to adjust and combine them.

Of the tools that can be useful at work, experts call a welding machine, a drill or a full-fledged drilling machine, a grinder with roughing and cutting discs, as well as a special device equipped with rivets.

Many professionals recommend, in addition, stock up on oil paint for metal or a special tool with a polymer filler. In the second case, the painting will be more stable and the body will not have to be painted again by the end of the season. Paint coating is carried out prior to assembly of large trailer parts.

Designing a simple cart

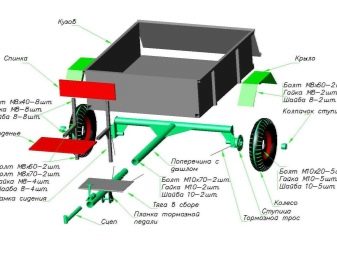

The simplest trailer can carry from 450 to 500 kilograms of cargo and can hold approximately 8 full bags of potatoes. If you study the drawing, it becomes clear that the self-propelled cart will consist of such typical elements as a body, carrier, frame, wheels and others. The frame will be best welded from cut tubes with a round or rectangular cross-section, as well as iron corners. This should be done on a flat surface, and using electric arc welding. During work, it is necessary that the seam is uniform at all joints, which are then sanded with a grinder. The resulting structure will be able to operate in areas with irregularities and small differences in height. A body with a skeleton is usually fixed using pins.

In addition, the installation of springs is recommended to minimize the shaking that occurs when driving through potholes.A dump cart cannot function without the aid of a wheel axle, which is a pin 1 meter long, the diameter of which does not exceed three centimeters. It is important to make sure when choosing a rod so that as a result its wheels do not go beyond the boundaries of the body. It will be possible to assemble the parts by welding through the support corners, as well as the frame beams with kerchiefs with longitudinal hinges. By the way, since the main load will fall on the point where the trailer is directly connected, as well as on the turning zone, they should be additionally strengthened.

The body of the dump trailer is made either of metal or wood - planks or plywood. In any case, the thickness of the material should be at least 20 millimeters, and it would be better to strengthen it with steel corners. Props are required to connect the frame and body. In their capacity, by the way, there can be strong 50 by 50 mm bars available on the farm. The center of gravity should not cross the straight line of the wheel pin, and stiffeners are required from below and from the sides.

In addition, it is important to consider the purpose for which the cart will be used. If bags with cargo will be transported in it, then folding sides are not at all necessary. Nevertheless, for unloading, it is worth providing an opening rear wall of the body or tipping mechanisms for turning the device over. Of course, all sides are allowed to be fixed. In addition, they must be smooth on the inside.

In order for the resulting trailer to join the existing walk-behind tractor, you need a special part called a console. In this case, the connecting mechanism must be removed into the cylindrical body of the longitudinal hinge and secured with a special thrust ring. This will make it possible to create the independence of the cart wheels from the wheels of a walk-behind tractor or other agricultural machinery, which means, to simplify the process of driving a moving vehicle. The hitch is formed from any suitable metal piece, the length of which is determined so that the transport device is convenient to operate.

Wheels are usually assembled from scrap materials. - tires of a motorized sidecar, combined with the central part taken from other spare parts. Both axles are sharpened to the diameter of the bearings of the motorcycle hub taken from the sidecar. For the wheel axle, a steel circle is required, the diameter of which reaches at least three centimeters, which will then be welded together with a longitudinal hinge and corner supports.

The bottom of the cart itself is more convenient to design from a metal plate, the thickness of which varies from 2 to 3 millimeters. Edged board, which is more affordable, but less stable, will also work.

Among other things, a seat and a footrest must be created for the driver. The seat is either attached to a hitch or mounted directly in the body.

The need for brakes

Undoubtedly, it is worth adding a braking system to a homemade trailer. Otherwise, any descent from the hill can end in tragedy. The brakes on the cart are usually removed from another vehicle, for example, a regular car or walk-behind tractor. The parking mechanism is considered the most suitable: it can be used to fix the trailer in an immovable state for a long time, stop it while driving, or even leave it at an angle. You can use the brake by pressing the lever or pedal.

To provide the trailer with the above function, an optional motorcycle brake drum and pads are required., as well as the spokes, again, of a motorcycle wheel. The implementation of the direct alteration will take place using a welding machine and pliers. Pre-used discs are freed from cables and rods and sharpened by a specialist. Next, the drums are put on the hubs and fixed at the back.The resulting empty space between the ribs will have to be filled by wrapping the ribs themselves with ordinary metal wire.

At the next stage, the discs are arranged on the axle and fastened with bushings. In addition, it is worth welding a small fragment of a metal part, for example, a corner, to the axle to prevent the disc from moving. The cables are mounted on drums and reach the place where the driver can activate the brake, usually a lever or pedal.

For information on how to make a trolley for a walk-behind tractor with your own hands, see the next video.

The comment was sent successfully.