All about carports made of metal profiles

Today, carports made of metal profiles are much more common than structures made of wood or brick. This fact is due to a small investment, strength and reliability of the finished structure. But most importantly, such protection from bad weather can be built independently, you should only adhere to the construction technology and the rules for working with shaped pipes.

Peculiarities

A carport is a small architectural structure with strong supports and missing walls. The main function of the canopy is to protect the car from bad weather. However, in a summer cottage, in a covered area, you can arrange a picnic or temporarily put a children's pool. A properly designed roof can protect a person and his car from the bright sun on a clear summer day, from snowfall in a harsh winter and from rains in the autumn and spring.

In addition to the main purpose, awnings play an important role in the decor of the yard, especially metal profile structures. It is they who can be supplemented with unusual patterns of forged metal, if necessary, change the color of the entire canopy or some elements. The metal profile used in the construction of a carport has many advantages.

This material is resistant to biological, chemical and mechanical stress. In simple words, the metal profile is not afraid of sudden temperature changes, easily tolerates fire, and with appropriate processing it does not become rusty. In addition, square or rectangular shaped tubes are easy to install, maintain and maintain. And what is most attractive, this material is environmentally friendly and low cost.

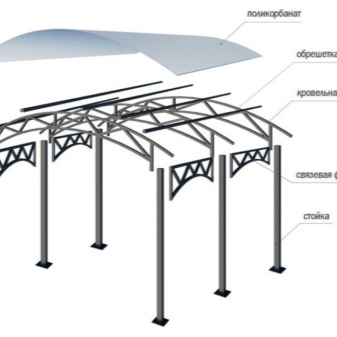

The protective structure itself consists of a foundation, vertical supports, side connectors, trusses, lathing and roofing. However, people who are not associated with construction, from the presented list, are familiar with only a few words. Accordingly, there are thoughts that it will not be possible to build a canopy without qualified specialists. But this is a misconception. Any modern person will be able to independently install a canopy from a metal profile, the main thing is to follow the instructions.

How can it be?

Having decided to build a carport from a profile pipe in the country, it is important to think about what the structure should be. A lot of ideas come to mind, each of which has an impressive list of advantages and some disadvantages. And the most important thing is to decide what shape the roof should be.

- Single-slope option. This type of canopy is considered the easiest to perform. It is very comfortable, practical, has one bevel. You can cover the roof with corrugated board, metal or polycarbonate. The main thing is to find the right angle of inclination. If the canopy is steep, rain will drain off the roof immediately and unimpeded. Unfortunately, along with the indisputable advantages, lean-to sheds have some disadvantages. Firstly, it will not be possible to save the car from slanting rain; in such a situation, drops will fall under the canopy. Secondly, in a hurricane wind, a single-pitch "sail", despite the strength of the fastening, can break. Another important nuance in the construction of a pitched roof is the arrangement of a rainwater drainage system.

Otherwise, soil erosion may occur, the supports will not withstand, and the entire structure will collapse.

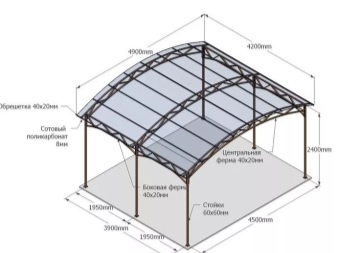

- Gable version. This design involves the installation of a triangular roof made of corrugated board, although any other material can be used for roof sheathing. Such a canopy saves from precipitation accompanied by variable wind. Gable canopies made of metal profiles are characterized by a high level of strength and reliability. The correct location of the planes at a certain angle relative to each other guarantees the stability of the canopy in any bad weather. In the case when the covered parking is designed for several cars, it is necessary to make additional roof reinforcement.

- Multi-slope option. Quite an interesting and very unusual canopy, reminiscent of a series of cascades of gable roofs. Of course, it is very difficult to build such a structure on your own. Most likely, you will have to invite builders. The complexity of the installation of a multi-slope canopy is due to the selection of appropriate materials, their connection, calculations and arrangement of the drainage system.

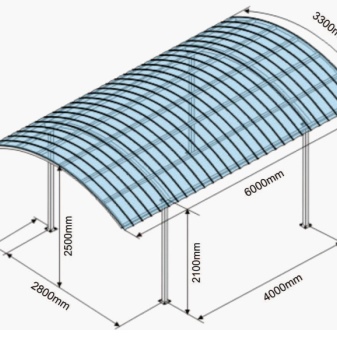

- Arched option. This form of a canopy from a professional pipe is not only the protection of the car, but also the decor of the entire site. It is rather complicated in execution, not every person can build it on their own. But despite the beauty, practicality of the structure and other quality parameters, the arched canopy has one drawback - the high cost. For work, you will have to purchase special tools, elements for strengthening the structure and, most importantly, arched arcs. For their sheathing, polycarbonate should be used, the profiled sheet will have to be abandoned, since it is impossible to bend it to the required shape at home.

How to do it?

It may seem to someone that making a canopy from a metal profile with your own hands is very difficult, but if you know all the intricacies of the work, you will be able to build a unique structure on your site to protect the car. And before starting construction, it is suggested to get acquainted with a few tips from professionals.

- First you need to draw up a drawing of the future building, which will indicate the overall dimensions of the structure and each individual part. To calculate the lengths of supports dug into the ground, you need to ask local architects for the depth of soil freezing.

- To work, you need to know the principle of operation of the welding machine, and it is best to have experience with it. In the absence of welding, roofing screws can be used. By the way, they will look much more impressive.

- The installation of the canopy should be started from the bottom. Other options are not even considered in this case. It is trite to put a roof on non-existent supports only a wizard can.

- Each metal structural element must be treated with an anti-corrosion compound.

- It is best to lay a wavy profile on the roof of the canopy. Through it, rainwater easily flows to the ground. Use metal shears to cut the profile. They do not harm the protective layer of the material.

Making a canopy from a metal profile is as easy as shelling pears. Of course, you will have to spend some time on the construction of the structure, invest a certain amount of money and show maximum patience. In no case should you rush, otherwise fixing an error can cost a pretty penny. First of all, you need to make a drawing.

Blueprints

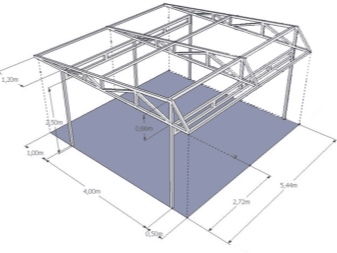

First you need to determine the location of the future carport. The choice of material for the main structure and roof framing depends on this. It is worth choosing a flat place on a hill for the canopy in order to design a good drainage system. When constructing a covered parking in the lowland, it will be necessary to supplement the structure with a storm drain. Having decided on the place, you should start preparing a plan, which will indicate a detailed diagram of the site with all the buildings on the territory. Based on these indicators, it will be possible to calculate the required material. For example, if the dimensions of the canopy are 4x6 m, it is recommended to use a 60x60 mm metal profile for the supports.For larger structures, 80x80 mm pipes should be used.

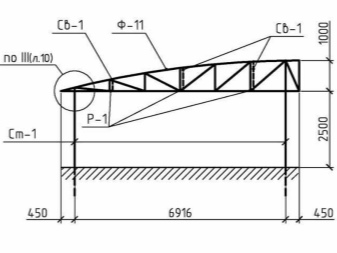

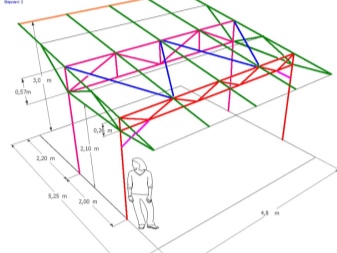

Next, a calculation is made to determine the length of the pipes used to create the trusses. For pitched roofs, you should know the angle of inclination and use the formula c = b / cosA to find out the required figure. In this case, b is the width of the structure, A is the angle of inclination. The heights of triangular trusses are calculated using a similar formula.

To clarify the length of the arch of an arched canopy, it is necessary to know the exact height of the arch (in the formula, h has a value). The formula itself sounds like this: c = (h + b / 2) x1.57. The final stage of miscalculations - it is necessary to establish the optimal distance between the supports of the structure and the trusses. Usually this indicator fluctuates within 1-2 m. It all depends on the mass of the roof. The connection of the supports is carried out by trusses.

A separate drawing should be drawn up for trusses. This will help the self-taught master not to make mistakes when erecting a structure. On the truss plan, struts and internal supports should be drawn. For the speed of drawing up drawings, it is worth using special computer programs. With their help, it will be possible to identify a random error in the calculations and correct it before the start of construction.

Foundation

Having a project with specific drawings, you can get to work. You should start with the foundation. A place is selected on the territory of the site, it is desirable that the surface is flat. But in any case, the top layer of soil will have to be leveled, get rid of the grass. To lay paving slabs or asphalt, you will have to remove 30 cm of soil. Then lay agrotextile - a material that prevents the germination of grass and plants. A little sand and crushed stone are sprinkled on top. Sand is reintroduced under the tiled layer, and crushed stone under the asphalt.

It is important to carefully read the master plan of the site and find communications that run underground. If the pipe breaks or the wire suddenly breaks, it is likely that you will have to disassemble the canopy to fix the problem. Having cleared and leveled the soil, it is necessary to dig holes 80 cm deep to fix the supports. Sand is poured to the bottom, crushed stone on top. Then supports are placed in the pits and filled with cement mass. It is important to ensure that the supports are level. To check, you must use a level.

There are several more ways to install supports, however, they are not simple and most often require the help of friends or neighbors. If groundwater flows close to the surface, a drainage system should be installed around the perimeter.

Frame

Having installed supports for the future canopy, it is necessary to start designing the frame. First you need to align the support pillars, then weld short, and then long elements. Before welding, it is recommended to thread pipe sections with clamps so that they do not dangle. On a free piece of land, according to the drawings, farms are assembled. Holes are made in them for fastening the roof. Welded trusses are lifted and fixed to each other. It is possible to cook structural elements at a height, however, under such conditions it is very difficult to keep track of the evenness of each individual element.

It remains only to clean the frame from welding slag deposits. After the joints are covered with paint and varnish. It is these areas of the structure that are most susceptible to corrosion.

Roof

Various materials can be used in the manufacture of a canopy canopy. For example, slate. This roof covering is familiar to everyone. Due to the rather large weight of each sheet, careful calculations of the load on the frame trusses are required. The only drawback of this material is the meager assortment. Another option for roof cladding is corrugated board. This material is simple and easy to install, and its price, in principle, does not differ from slate. Today the corrugated board is represented by a wide assortment range.Thanks to the many textures and colors, everyone can choose an option that is ideally combined with other buildings on the site.

Nevertheless, cellular polycarbonate is in great demand. Reasonable price, ease of installation, aesthetic appeal - these are the main parameters for which polycarbonate has become a favorite material for facing the roof of canopies. It can be used to design roofs of various shapes and sizes. In general, the installation process depends on the selected material. Special self-tapping screws have been developed for polycarbonate. If the choice fell on slate or corrugated board, you will have to buy additional waterproofing. Slate sheets are laid out from bottom to top, overlapping each other so that rainwater does not flow inside.

Beautiful examples

Having understood the technology of building carports, everyone will be able to build a unique structure from a metal profile on their site. A for inspiration, it is proposed to look at several ready-made options that emphasize the beauty of the site.

How to make a canopy from a metal profile for a car with your own hands, see the next video.

The comment was sent successfully.