All about polycarbonate awnings

Today, polycarbonate is the most popular material for awnings. Its light transmittance, lightness and strength are best suited for the installation and operation of the roof over any summer buildings in the adjoining territories.

Features, pros and cons

Polycarbonate is a versatile material for canopies. It is being erected over a parking lot, a playground, a recreation area, and large-scale coverings are installed over the entire courtyard, from the gate to the porch of the house. Yards under polycarbonate canopies always remain light and clean, as the material is able to transmit light and protect from bad weather. Studying the characteristics of this polymer, you find more and more advantages in it.

- The transmission capacity of the sun's rays is 75-95%. At the same time, polycarbonate evenly scatters light and traps dangerous UV radiation.

- The material is 100 times stronger than glass and 10 times stronger than acrylic.

- It can withstand a temperature run from - 45 to + 120 degrees.

- The polymer is harmless to health and fire resistant.

- It has a long service life, is resistant to abrasion and mechanical damage.

- The low weight of the roofing sheets does not create large loads on the supports and allows for self-assembly.

- The canopy is easy to maintain.

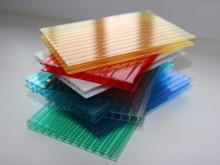

- Polycarbonate is available in a wide range of colors and types.

- It is flexible, you can create roofs with beautiful curved lines from it.

- The lightness and airiness of the material allows the awnings to be built into any landscape design.

- On top of the voiced advantages, you can add the loyal cost of polycarbonate, which also gives it popularity.

There are very few downsides to the material, but they are also available.

- You should purchase a product with a protective coating, otherwise it can be scratched.

- Chemical reagents leave stains on the surface, but, as we understand, we do not often have to deal with them.

- The material has a wide thermal expansion, so for installation you have to use special fasteners and leave gaps between the sheets.

The industry produces several types of this roofing material - monolithic, profiled, honeycomb.

Monolithic

The most durable and transparent type of polycarbonate, it looks like glass, but twice as light, transmits up to 95% of the sun's rays. Colored and colorless materials have varying degrees of transparency. On sale you can find sheets with a thickness of one to 20 mm. The parameters affect the bending radius of the material; the thinner, the more ductile.

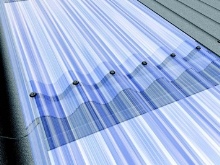

Profiled

According to its characteristics, this is the same monolithic look, but it does not look like a flat sheet, but has a broken surface with clear lines or is presented in the form of a wavy shape.

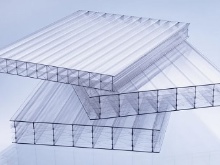

Cellular

It is also called structured or cellular for the appearance of the sidewalls of the sheet. This type of polycarbonate is obtained by adding two surfaces, between which an even row of bridges is installed, as a result, in the section, the product has uniform holes (cells). Multilayer plastic is formed by folding 2-7 sheets with jumpers. It is this material from the end that vaguely resembles honeycomb cells of bees.

The structured shape allows the product to fill with air and become light (6 times lighter than glass), airy and as strong as possible. It has twice the sound insulation performance of glass, 80% light transmission and good heat retention. The plasticity of the honeycomb polymer makes it possible to make canopies from it in the form of arches, waves, domes. The degree of flexibility and weight of the material depends on the number of layers.

Types of structures

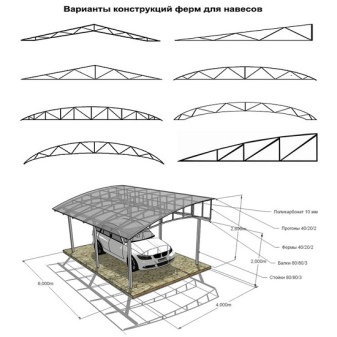

The flexible properties of polycarbonate allow for a wide variety of awnings. Structurally, they differ from each other in the form and type of supports. Depending on the choice of the project, you can create buildings of different types, from the simplest single-pitched canopies to complex multi-tiered or domed roofs.

By type of support

Supports are made of metal, wooden beams. Expensive and spectacular types of awnings are made in the form of forged structures or with the participation of carved wooden pillars. In the creation of trusses, a profile pipe and thinner metal profiles are used.

Metal

The metal is used to create supports, frame and trusses. After concreting the metal piles, they proceed to the creation of trusses, on which polycarbonate sheets will be installed in the future. Separately, with the help of welding, the girders are assembled, then they are mounted on supports, performing a frame under the roofing. A steel profile with anti-corrosion protection is chosen as the material.

Sometimes spectacular openwork forging is used to create a frame. It is especially appropriate if the site already has forged products, for example, a balcony, a gazebo, a swing. For hot forging, aluminum, steel, titanium and all kinds of ductile alloys are used. To carry out cold forging, you need a sheet base.

Elements of the most expensive sheds are covered with a thin layer of copper, silver and even gold.

Concrete, brick, stone

Polycarbonate roof supports are often built from materials such as concrete, stone and brick. They are strong and durable, but unlike iron piles, brick and stone supports will need to calculate the amount of material required, as well as the load to withstand. Concrete supports require further front finishing, and brick and stone themselves look expensive and presentable.

Wood

It is not difficult to install a prefabricated timber frame; it is enough to have basic carpentry skills. For racks and strapping you will need beams, and for fastenings - various hardware. The details of the frame are prepared in advance, processed with antifungal agents, this process can take a week, but the assembly itself takes place in one day.

Wood is inferior in strength to metal and stone, it swells from rains, from heat it cracks, but the beauty and natural energy of such sheds become weighty arguments in their favor. In addition, they organically fit into the green massif of the garden.

By the shape and number of stingrays

From polycarbonate sheets, you can make a round, arched, semi-arched, cantilever type of canopy, as well as a straight canopy with a gable or gable closed roof.

Single slope

The canopy has a single straight plane directed downhill. The angle of inclination depends on the footage of the surface, it is calculated in such a way that snow and other types of precipitation do not linger on the roof. Shed sheds are often mounted to the walls of buildings, and the second, lower side is installed on supports. A similar type of canopies can be built separately, for this, piles on both sides are made of different lengths.

Gable

The double slope canopy is classic. It is chosen if they want to duplicate the shape of the roof of a residential building, in which case the supports are built from the material of the main building. The slope of both planes is approximately 40 degrees, which is enough for the snow to leave the roof under its own weight.

Gable roofs are used for free-standing canopies or canopies located at the entrance to the house.

Arched

Polycarbonate of any kind bends well, and it is not difficult to give it a semicircular shape. Snow adheres to the arched surface least of all and creates almost no pressure. This type of roof better than others protects from wind and slanting rain, redirecting them away from the canopy.

Conical

The canopy is made in the form of a cone, but more voluminous dome forms are often referred to such types. Such structures have the most attractive appearance, they are built to implement certain design solutions that make up the overall stylization of the landscape. It is quite difficult to build such a canopy, you need to correctly calculate the thickness of the material, the load force, the direction of the cells, the radius of the curved line of the dome.

Complicated

Aesthetically very beautiful canopy consisting of multi-level surfaces. If it is adjacent to a house, the roof of the building is included in the overall architectural ensemble of the roof.

Color selection

The first sheets of polycarbonate were transparent. Today the industry produces this product in a large assortment of colors. Light transmittance is influenced not only by the thickness of the polymer, but also by the specific color of the material.

- Transparent. Has the highest solar radiation transmittance, up to 95%. Does not scatter light or create shadows, useful as protection against precipitation. It is better to choose it for those places where natural light is important. It is good for them to cover greenhouses so as not to disrupt the process of photosynthesis. Other types of polycarbonate are classified as translucent materials, with varying degrees of light transmittance.

- Opal. This color can be considered 50-75% transparent.

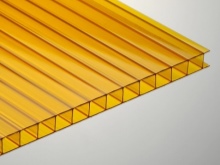

- Red, yellow, green, blue, gray, orange, brown. Polymers of the listed shades scatter light and are endowed with 45-55% transparency. Under such a roof it is neither dark nor hot, therefore the materials of these colors are used to create awnings.

- The light transmittance index of bronze colors is 25-40%, they are also suitable for visors.

- Silver and snow white material has 25% light transmission and creates a good shadow, which is an invaluable quality for the southern regions of the country.

- Very low bandwidth in gold and red polycarbonate.

Where to place?

Sheds are used for different purposes, so their purpose is directly related to the location.

- Covered parking for a car can often be seen adjacent to the garage or utility block. The structure is located at a close distance from the gate with a free entrance that does not intersect with the active zone of the yard.

- Large awnings (from the gate itself to the front door of the house) cover the entire courtyard, along with a bench, a porch, allowing it to be clean even in heavy showers.

- You can make and install a protective visor in the drying area, then it is not scary to miss the rain and not to remove things from the rope in time.

- A covering device over the playground will protect children from overheating.

- Beautiful translucent roofs are erected over a bench, gazebo, veranda, terrace.

- In the recreation area above the brazier or barbecue oven, protective awnings are also appropriate.

In such places, another 1-2 walls are built, taking into account the direction of the winds, in order to protect the living fire from extinction.

How to do it yourself?

A simple polycarbonate canopy is not difficult to do on your own. It is lightweight and easy to install material, it does not crumble or crack during cutting. We will tell you in more detail how to build an arched covering with your own hands.

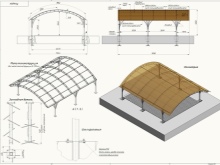

Drawings and dimensions

Before starting construction, you should decide what kind of canopy you need - car, over the gazebo, yard, barbecue area. It is worth finding a place for the upcoming construction, the size of which will directly depend on the possibility of the territory. Then draw up a diagram of the future structure, calculate the load of the roof on the supports (taking into account the snow). It is also necessary to select the material for the canopy and calculate its quantity.

Building material is purchased with a small margin so that it is possible to cover random errors.

Frame fabrication

Work on the structure begins with the construction of supports. To do this, it is necessary to clean and level the area allocated for the canopy. Then, according to the sketch, using a rope and a peg, make markings for the supports. Depressions (50-80 cm) should be drilled or dug out with a shovel, and sand and crushed stone should be poured into the bottom. When the pits are ready, it is necessary to install supports in them, level them with a level and fill them with cement. If the canopy is large, in addition to the corner columns, intermediate columns are mounted in increments of 1.5 or 2 m.

When the concrete dries out, a strapping is made along the upper edge of the supports using a profiled pipe. Then they move on to the manufacture of farms, they are collected separately. First, a template of one run is made, small metal parts are attached to it by welding. The rest of the runs are made following the example of the first. The finished structures are lifted and welded to the profiled pipes of the upper strapping.

The weight of the structure should be taken into account, each truss will pull 20 kg, they will have to be installed by two or three people. At this stage, you can already fix the drain.

Mounting sheet

Cutting and laying of polycarbonate sheets is carried out according to the drawing. To do this, markings are made on the material with a felt-tip pen, with the help of a circular saw, the plastic is cut out, then the ends are freed from adhering chips. When cutting, you should take into account the direction of the cells of the cellular polycarbonate. The sheets should lie down so that condensation does not accumulate in them, but has the ability to drain under the slope of the roof.

The sheets are mounted using temperature compensating washers. It is necessary to dock the seams so that they coincide with the metal profile. Gaps of up to 3 mm are left between the sheets, for the expansion of the material when heated in the sun. Fastening to the edge occurs no closer than 4-5 cm. The joints are covered with profile tapes with a seal, matched to the color of the polycarbonate. The upper ends are hidden under an aluminum tape. The lower joints are hidden by perforated protection, which makes it possible for condensate not to linger in the cells of the material.

What can replace polycarbonate?

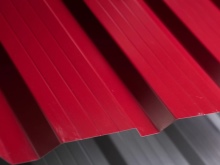

Decking may be a good alternative. It has a number of advantages to make a choice in its favor.

- Durability. Profiled sheets are made of steel and coated with polymer or zinc. They are resistant to mechanical stress, are not afraid of loads, do not rust and can serve as a canopy for up to 50 years.

- Color selection. The industry produces material with a wide variety of colors, it can be selected for every taste and for any design.

- Strength. The metal base of profiled sheets is superior in strength to any other types of roofing material - wood, polycarbonate, glass, tiles.

Before deciding to use a profiled sheet instead of a polymer, you should also familiarize yourself with the shortcomings of this material.

- To avoid corrosion, it is necessary to view the canopy and touch up areas with a damaged protective coating.

- This material is capable of making noise; under such a roof you will not fall asleep during rain, hail or strong wind.

In addition to corrugated board, awnings are covered with bituminous tiles, boards, roofing felt.

Care and repair tips

Polycarbonate sheets damaged during operation must be dismantled and replaced. If the canopy begins to leak, you should check the tightness of the joints. It is not difficult to restore the integrity of the coating. In winter, you need to make sure that snow does not accumulate on the roof. It is also necessary to remove foliage and dry branches. You should periodically wash the structure under the pressure of water from a hose.

If you have access to the surface of the canopy, for example from the roof of an adjacent building or a ladder, you can do more thorough cleaning with a long mop with attachments and an alcohol-based detergent. This will give the roof a renewed shine.When cleaning, do not use abrasive products, they can scratch the plastic.

Beautiful examples

Polycarbonate awnings are varied, light and airy. Elegant spectacular designs can become the pride of any suburban area. To do this, you should choose a building that meets the style of landscape design and the taste of the owner. We suggest that you familiarize yourself with examples of beautiful polymer awnings.

- Sliding structure above the pool.

- Covering above the terrace made of colored monolithic polycarbonate.

- Modern illuminated awning design.

- A wave-shaped roof looks aesthetically attractive.

- The original protection over the recreation area is a monolithic polymer on a wooden frame.

- A transparent air canopy with a curved outline.

Sheds in suburban areas are not useless. Under them you can hide the car or hide yourself from the rain and sun. If you try, such structures can become a real decoration of a garden or local area.

For information on how to make a polycarbonate canopy with your own hands, see the next video.

The comment was sent successfully.