How to choose and solder a plug to the headphones?

If you use headphones frequently, the plug will inevitably break. You will learn what to do to identify and correct this problem. We will tell you how to properly solder the plug for 3 and 4 wires, as well as give advice on repair and further operation.

Views

Different audio equipment has different connectors, which differ not only in size, but also in functionality. Therefore, there are several types of plugs:

- Micro Jack 2.5mm (TS / TRS / TRRS). The field of application is portable audio equipment, some video cameras and microphones. Previously, this standard was used in mobile phones.

- Mini Jack with a diameter of 3.5 mm (TS / TRS / TRRS). An interface familiar to many, which is used in modern computers, smartphones, tablets, audio equipment and many other places.

- Large Jack with a diameter of 6.25 mm (TS / TRS). Used in stationary professional equipment, amplifiers and karaoke devices.

- USB... Some full-size computer headphones have this connector.

- USB Type C. This is a new interface for connecting a mobile headset. It is still poorly distributed, mainly USB Type C - mini Jack adapters are used.

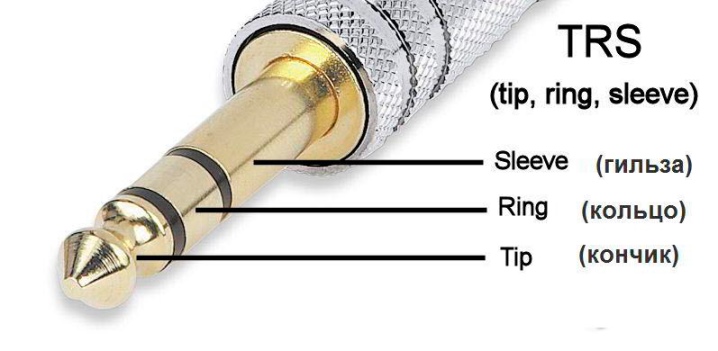

Latin letters in Jack-type connectors indicate the number of pins. It is loosely related to the size of the plug, but manufacturers usually follow the above classification. Each letter means the following:

- T - Trip (latch). This is the "nose" of the plug, its very beginning.

- S - Sleeve... The end of the plug, which bears against the plastic housing.

- R - Ring (ring). Located between these two contacts.

Some mono audio jacks may not have it. Others, where a microphone or noise cancellation system is used, may have multiple R pins.

The number of wires included in the connector may vary depending on the functionality and purpose of the connected headset:

- 2 wires... Previously used for the transmission of mono sound in the simplest designs of audio equipment (for example, detector radios). Nowadays, they are sometimes used to connect microphones.

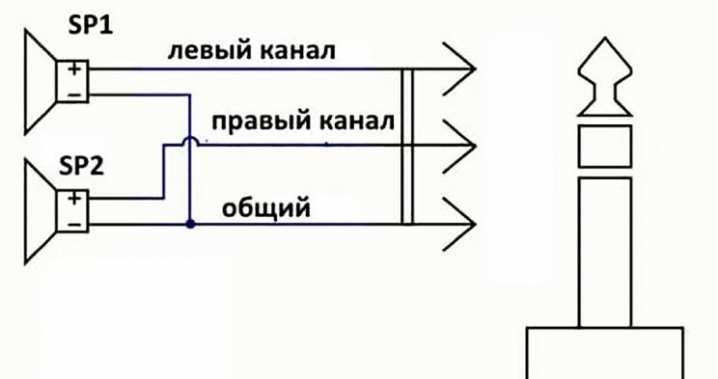

- 3 wires. This scheme applies to both stereo and mono sound (then the left and right channels are connected together).

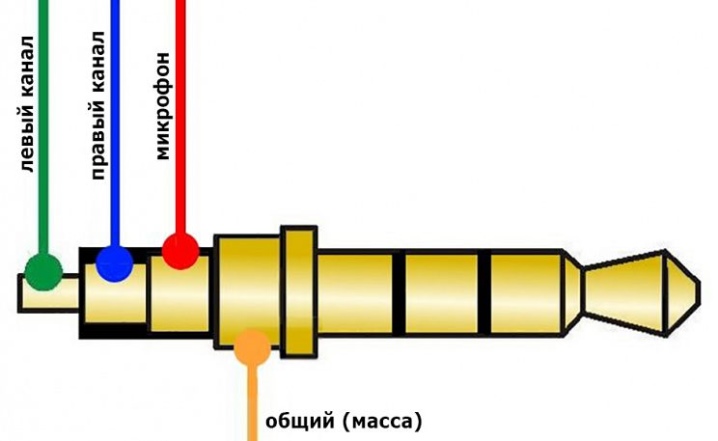

- 4 wires. Such a connector is needed to connect a stereo headset, that is, headphones with a microphone and a control button. The button is connected in parallel with the microphone.

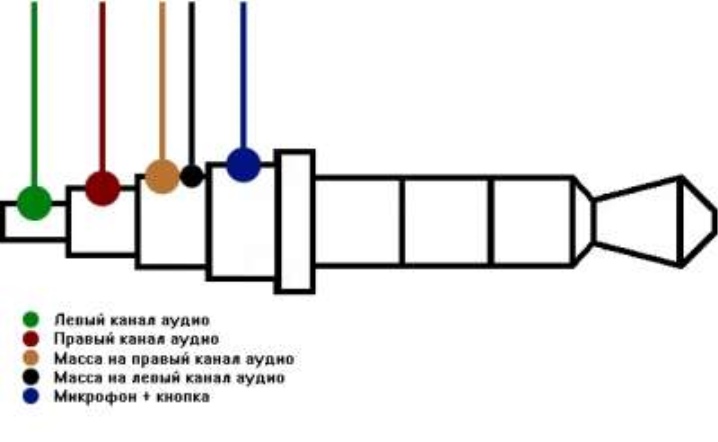

- 5 wires... It is used in an expensive headset with an active noise cancellation system. And when to improve the sound quality, the microphone with the control button is connected to the base with a separate cable.

Sometimes only 4 wires can be visually observed in a 5-wire circuit. This is because the copper braided microphone cable is used as the 5th conductor. Be careful when repairing such a connector.

For ease of use, the wires are color-coded:

- Right channel - Red.

- Left - green, blue, white and other colors.

- Common contact, or ground - copper.

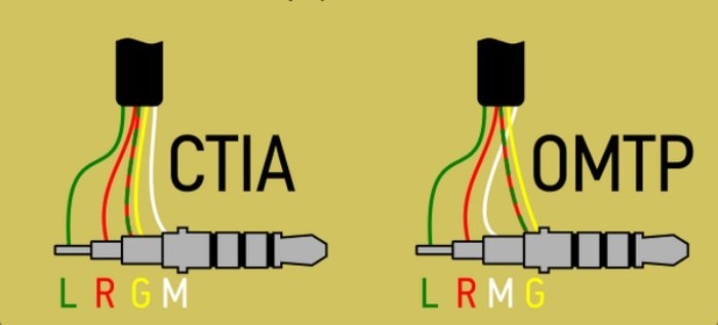

But not everything is so simple, some unscrupulous manufacturers use wires of the same color. Then, to repair the headphones, you need to completely disassemble and ring each cable. In addition, even externally identical connectors have different pinouts - CTIA and OMTP.

Failure to solder such a plug can damage the microphone. Even if it doesn't come to that, the sound will be distorted anyway.There is only one way out - re-solder the plug... Typically the CTIA wiring diagram is used. The OMTP variant is found in cheap Chinese headphones.

On sale there is special adapters from CTIA to OMTP and vice versa. As you can see, it's not easy to solder the plug correctly. The main difficulty is to correctly calculate the purpose of each wire. But first you need to clearly identify the malfunction.

How to identify a malfunction

Signs by which you can determine the breakdown of the plug are as follows:

- There is a lot of noise, the sound is distorted during playback.

- One speaker or both are not working.

- Microphone does not work.

- Active noise cancellation does not work (if provided by the headset design).

- The sound disappears, and if you move the plug, it appears.

- The headphones only work with a certain plug position.

- There is visible damage to the plug or kinks in the wire at the connection.

- The plug came off completely.

To test the operation of the headset, pair it with a source that is known to be working. The main thing is to determine that it was the plug that broke, and not the speakers. To check them, turn on the multimeter in continuity mode and connect its probes to the wires from the speakers. A sound speaker should emit rustles and clicks (but quiet, and you need to listen to them). When a plug is found to be faulty, do not be discouraged. Anyone who knows how to hold a soldering iron can carry out repairs.

How to solder headphones to the plug

For repairs we need:

- a sharp knife or scalpel;

- nippers or side cutters;

- tweezers, plectrum or flathead screwdriver;

- soldering iron, solder and flux;

- lighter;

- hot melt glue and glue gun;

- spare plug.

Do not use flux containing acid or alkali. In our case, pine rosin works well.

You may not need all of these items. But repairs are unpredictable, so having a stock of parts will never be superfluous. When all this is ready, you can get to work. There are 2 ways to repair headphones: use the old connector or replace it with a new one.

The repair begins in the same way:

- Use pliers to cut off the old plug at a distance of 2-3 cm from its edge.

- Strip the wires from insulation (it is advisable to make the common contact a little longer).

- When making a headset, a silk thread is woven into the cables, which increases their mechanical properties. The wire must be untwisted, the thread must be removed.

- Strip the cable from the varnish insulation. It can be removed with a knife. Or use a lighter and then use a blade to remove carbon deposits. Also, the varnish is well removed by tinning when the wire is immersed in a puddle of rosin and calcined with a soldering iron. There should be some solder on its tip.

- Correctly determine the purpose of each wire (this is called a pinout). The speaker impedance of in-ear headphones is typically 32 ohms.

- Solder all ground wires together.

It is also possible to use aspirin as a flux, which is clearly shown in the following video:

Next, choose between repairing the old plug or replacing it. The new connector can be soldered immediately, there is no need to do preparatory operations with it (except for cleaning and tinning the contacts). There are different models on sale for 3, 4 or more wires. But they are not without drawbacks:

- The hole for the wire is very large, you need to fill it with something. For example, hot glue or sealant.

- The mass and dimensions of the new plug are larger, and this does not add some convenience. And its appearance can be very different from the general style of the headphones.

- The material of the connector pins is less suitable for soldering.

- A poor quality plug can loosen the socket on the source.

All these disadvantages apply only to the cheapest connectors. To avoid them, buy only quality products. Then replacing the connector will not be difficult. Before soldering, be sure to attach all required plug parts to the cable. Even experienced craftsmen sometimes make this mistake. You can re-solder the old plug, for this you need to act carefully:

- Cut the plastic insulation along the seam and remove it.

- Take a photo of where each wire is soldered.

- Strip the contacts on the plug.

- Slide the heat shrink tubing and new housing over the cable. This can be a cap from a ballpoint pen, a needle tip from a syringe, and more. Remember to adjust the dimensions to the plug.

- Solder the wires.

- Secure the new housing with glue and heat shrink.

Check your headphones. If the sound is clear and the microphone and noise cancellation are working, the job is done successfully. If not, inspect the soldering points, check the speakers and wires with a multimeter.

Advice

We can give you some tips for repair and maintenance that may be useful to you:

- Observe safety precautions, work in a well-ventilated area with sufficient light.

- To clarify the pinout of your particular headphone model, look for information on thematic sites or forums, as well as on the manufacturer's website.

- Do not overheat the plug when soldering. Its contacts are separated by plastic insulation, which can melt.

- For better cleaning of the wire from the varnish, you can use an aspirin tablet. You need to put the desired section of the cable on it and warm it up well with a soldering iron. True, then the wire still needs to be cleaned and tinned with rosin.

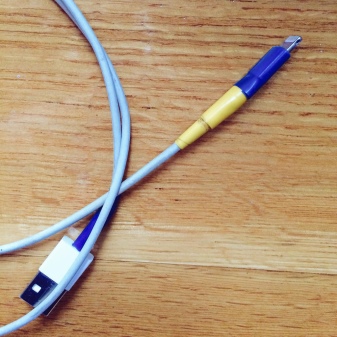

- To avoid further damage, make sure that the cable does not break at the point where it enters the plug. This place can be strengthened by putting on a spring from a fountain pen, wrapping it with tape or electrical tape.

You can get acquainted with a more detailed analysis and repair of the headphone plug in the following video.

The comment was sent successfully.