How to choose a tile adhesive?

To choose a tile adhesive, you will need to familiarize yourself with the features of each type of product. The result of the facing work depends on the quality of the selected material, so this issue should be taken seriously.

Features of the composition

The beauty of the tile, its even position on the wall surface, largely depends on the glue. It contains cement, various modifiers with sand screenings. It is the foundation upon which countless variations of magical formulas are created to ensure that the ceramic adheres firmly to the wall.

The glue provides a high-quality connection with different types of tiles: ceramic, mosaic, rubber and others.... He is able to hold PVC or expanded polystyrene products for many years. There are solutions that do not require special surface preparation, but there are solutions that work in conjunction with a mesh.

Some form a thick layer, while others differ in the thinness of the film.

To make their way to the counter, and then to the repair site, without exception, all products of this type must have the following characteristics:

- high adhesion to hold boards of different weight;

- high level of flow - this quality allows you to fill all the voids on the wall;

- high plasticity - to be evenly distributed over the surface;

- resistance to subzero temperatures;

- reduced hydrophobicity - so that moisture does not penetrate deep into the composition and does not reduce its strength;

- heat resistance;

- long service life;

- fast solidification.

When choosing a tile, you should pay attention to the description of the product, because the choice of fastening material must match or correspond to its properties. In addition to glue, a concrete-sand screed is also used to fix the tiles to the surface.... But it does not provide reliable laying, the tile slips during attachment, requires a long surface preparation and its service life is not so long.

Advantage of adhesive solutions in low material consumption during installation: even the smallest layer guarantees reliable adhesion of materials. The variety of formulations is wide, you can choose a product for any surface. It is easy to use, but requires certain skills and dexterity of the tiler due to its quick drying.

Types and characteristics

Adhesives are divided into three positions:

- cement-based substances;

- dispersion compositions;

- epoxy mixtures.

According to international standards, this product is divided into five broad categories.

Adhesives for interior decoration... This type of material is considered the cheapest. The mixture is used for the decoration of household premises. The composition contains a small amount of additives, but they do a good job with the tasks set, providing a tight adhesion of the tile to the base. High-quality masonry is guaranteed only for standard tile sizes of 20x30.

If there are no temperature changes and adverse effects from the surrounding atmosphere, such an adhesive has a long service life;

Adhesive mixtures with a high degree of adhesion... They are able to withstand increased loads.Due to its qualities, such glue is used to work with a substrate that is exposed to temperature extremes and dynamic influences.

As a rule, compounds are purchased for laying large tiles or natural stones. The material can be used for laying on an old veneer.

Standard adhesive mixtures... The second name of the material is universal glue. It is the most widely used product and is in high demand among installers. The mixture is used for interior or exterior work. Although this glue is called universal, it is not recommended to purchase it for working with tiles, the dimensions of which exceed 30x30. Also, do not use the solution in rooms with high levels of humidity and increased floor loads.

Floor Tile Mix... The composition of such material contains plasticizers, thanks to which the material fills all existing voids. Since the glue has a liquid consistency, it is not suitable for interacting with walls.

Moisture resistant glue... This composition was specially developed for finishing works in swimming pools and fountains. It is often purchased by owners of apartments and country houses for finishing bathrooms, open terraces. The composition of the mixture is identical to the glue with increased fixation, but it additionally contains modifiers.

Waterproofing adhesive has the following properties:

- repelling moisture;

- harmlessness;

- resistance to chlorine;

- increased adhesion, which does not decrease after a while.

Dry mixes

Cement is used as a basis for dry mixes. The key advantage of such a material is considered the possibility of its application on uneven walls, on which there are various differences in curvature. The adhesive is able to level the base layer.

Cement glue for tiles belongs to the category of dry mortars. The key component of the composition is cement, the proportion of which in the mixture reaches 90%. The rest is sand with modifying additives, so this glue is considered versatile and inexpensive.

Cement mixtures are easy to use. You only need to dilute the mixture with water, in a ratio of 3: 1. Many pavers use similar mixtures for leveling the surface.

When working, keep in mind that they are able to correct only minor defects in the base.

When choosing a glue for working with mosaics, pay attention to the color of the products. For such work, white mixtures should be purchased.

Two-component

Two-component mixtures are considered durable adhesives. They can be used when carrying out external and internal work on horizontal and vertical surfaces. Polyurethane two-component adhesives are popular, with which you can fix ceramic, earthenware, metal, and wooden products. As well as concrete, PVC tiles, polystyrene and absorbent substrates.

After hardening, the glue turns into a moisture-resistant and frost-resistant coating, which can be used in the installation of "warm floors". The material is highly durable, resistant to mechanical stress, vibration and chemical attack. The fast drying speed is also one of the advantages of the two-component adhesive.

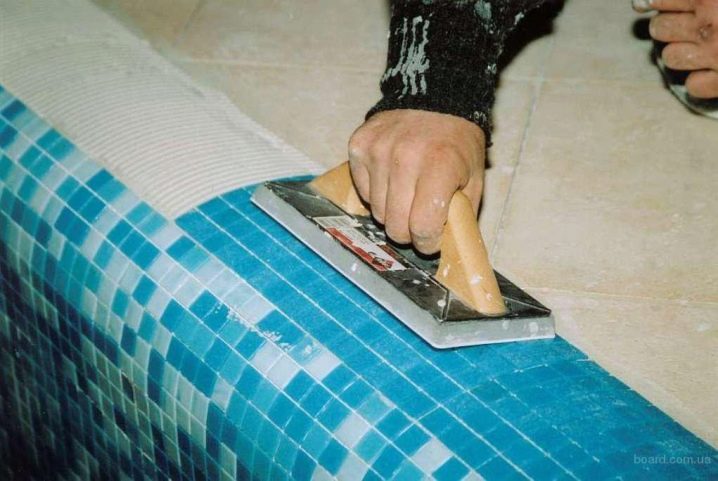

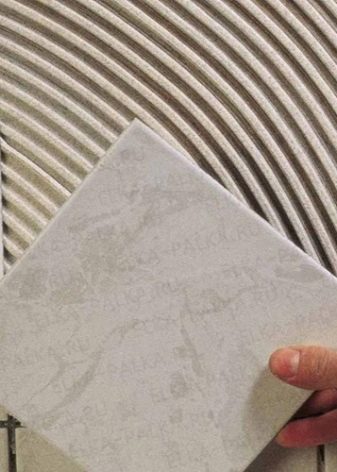

Mixtures should be used wisely. The sequence of actions for laying floor tiles is as follows:

- First of all, you need to open the glue.

- Then the hardener is added to the resin, after which the components are thoroughly mixed. Use a construction mixer for these purposes, the speed of which is 400-800 revolutions.

- It is necessary to mix for two minutes, then a break follows - 1-2 minutes.

- Then you need to mix the solution again. Its useful life is limited by the drying time. The coating is laid within 40 minutes.

- Use a notched trowel when working with such glue. The layer should not exceed 2 mm. It is necessary to firmly press the tiles to the surface and lay them by tapping. Tile rolling is carried out using a pressure roller, which allows you to completely remove air from under the plate.

- After three hours, you can start grouting and sealing the joints.

- You can walk on the surface after 3-8 hours.

Adhesives are classified as two-component solutions. This material is based on epoxy resin, supplemented with hardeners, solvents, fillers and plasticizers. It is necessary to strictly observe the proportions of mixing with water specified in the instructions.: Missed dosage can make the mixture dangerous.

The glue is elastic, does not shrink, and does not shine through porous products.

The mixture is sold ready-made, has great adhesion and can be used on any type of substrate.

Suitable for laying on surfaces that are not ideal in terms of smoothness: drywall, PVC, floating cement screeds, various types of metals, concrete and plaster. Used for tile-on-tile mounting.

Withstanding temperature range - from - 40 to + 100 degrees Celsius... The manufacturer calls its product waterproof, so it can be purchased for decorating swimming pools, laundries and bathrooms.

Ready

The finished compositions have a pasty form. The consistency gives the products advantages, which consist in saving time for mixing the mixture, the absence of dust particles and the invariability of the composition. The minimum time period during which it is necessary to use the glue is 40 minutes., which allows you to make maneuvers during facing work. Organic viscous additives, mineral components and other special substances have been added to the material.

Dispersion compounds are designed to work with ceramic tiles, mosaics, clinker products, glazed materials and natural stones. Cannot be used on lacquered MDF and DVF... When choosing such mixtures, keep in mind that they are intended only for interior cladding.

Manufacturers offer various options designed for specific conditions of use, but there are five main types that you need to familiarize yourself with before buying.

Quick dry

Such formulations provide drying and full use of the floor already 3-5 hours after laying material. They are suitable for laying porcelain stoneware and stone tiles. The material forms high-quality adhesion on mineral, non-deformed substrates.

Many masters recommend using it for cladding bathrooms, since such compositions are water-resistant. This type of mixture allows laying at low temperatures in an unheated room. Sale is carried out only dry.

Heat resistant

These compositions can be used at temperatures up to +100 degrees. Using such a solution in the bathroom is a waste of money. In most cases heat-resistant glue is purchased for laying tiles on fireplaces and stoves.

Only ceramic refractory tiles can be glued with this product.

It is not allowed to use with insulated, concrete bases, as well as in work with artificial stones. Heat-resistant mixtures do a good job of fixing tiles to aerated concrete and brick surfaces. Sale is carried out dry.

Frost resistant

These mixtures are sold dry. They are designed for fixing ceramic tiles. Such glue can be used for interior work in rooms with high humidity, for work on concrete and cement screed.

If you are working at room temperature, the operation should last no more than 2.5 hours.

Acid resistant

Acid-resistant adhesive mixtures are classified as two-component.This material is designed to work with acid-resistant tiles, which are installed in rooms with temperature changes and contact with external chemical irritants.

The advantage lies in the high-quality fixing of the tiles on a damp surface. The mixture quickly hardens, does not have an unpleasant odor and does not contain toxic substances.

Acrylic adhesive

This type of product is in great demand among professional craftsmen and amateurs. The substance has advantages over other compositions due to its elasticity, it can be used for tiles with different characteristics.

If you want to glue tiles on an OSB board, acrylic glue is best suited for this purpose.... Not every material is able to cope with this task, since OSB board is made of wood, which has poor adhesion to many cement mixtures.

In order for the acrylic glue to properly attach the products, you will need to securely fix the plate so that it does not bend or vibrate. Otherwise, you will face a situation where the ceramic tiles fall off from the base.

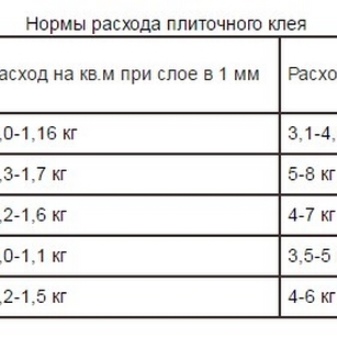

Consumption

The issue of tile adhesive consumption per square meter is always a key issue. Each person must correctly calculate the required amount of material in order to plan their expenses and not spend on surplus.

Each material absorbs glue in its own way, this property depends on the porosity of the products. Ceramic tiles absorb the least amount of glue, while cotto tiles increase the consumption of glue during installation.

Also, the consumable part is influenced by the dimensions, the type of surface and the method of laying.

Trademark and composition are also influenced. Since each brand uses its own type of additives in different quantities, the products have a different consistency, the consumption of each glue will be different... For example, if you use Eunice, you need 1 kg per square meter. Litokol consumption reaches 1.3 kg.

The installation specialists have already calculated the consumption of the popular ceresit glue. When working with 30x30 tiles, you need 4.2 kg per square meter. These indicators are relevant if you are working with a spatula, the teeth of which are 10 mm. Masters recommend purchasing only proven products that are popular.

Also, the required amount of glue is influenced by the temperature. The higher the indicator, the faster moisture evaporates from the solution, which leads to increased consumption... Do not forget about the experience of the master. Professional installers only use the right amount of glue, unlike beginners who can use up more product than they need to.

Approximate calculations of the cost of a cement-based adhesive mixture

Under positive masonry conditions, you will need 1.3 kg. This indicator must be multiplied by the thickness of the layer that is applied to the base. If you are using tiles with traditional parameters, the layer thickness will be 4 mm.

Multiply 1.3 by 4 to get 5.2 kg. You will need this amount of glue to work on one square meter. When working in a room with an area of 10 square meters, you will need 52 kg of adhesive mixture.

Consider tile sizes in your calculations... Depending on these indicators, the layer thickness will change.

Manufacturers rating

A special overview of products from popular manufacturers will help you in choosing the best tile adhesive.

Knauf fliesen

This product has performed well on difficult surfaces. The cost of a 25 kg bag is about 250 rubles. Glue is considered the best all-round option.

It can be used for laying wall or floor tiles, regardless of the type of base.

Product advantages:

- slow curing speed - allows you to adjust and clean the seams;

- savings in use - can be applied under the tiles in a layer of 7 mm, which guarantees high-quality fixing;

- elastic properties - it is necessary when working with difficult and hard-to-reach places;

- affordable price.

"Eunice 2000"

The brand is practically on par with Knauf. The product is considered the best tile adhesive in terms of adhesion power. The price is about 250 rubles for 25 kg.

Advantages of the mixture:

- correction within 10 minutes - this time is enough to correct shortcomings;

- universal composition of the product - the composition showed itself well even in different temperature conditions;

- high rates of elasticity - allow you to better cope with deformations of a temperature nature;

- ease of use;

- consumption 3.5 - 5 kg per square meter.

"Osnovit Mastplixt - 12"

Adhesive is considered the best option for those planning to install tiles on uneven surfaces. The cost of the product is about 250 rubles per 25 kg.

The glue differs from other brands in the following qualities:

- laying of tiles can be carried out together with assembly leveling;

- the mixture is characterized by excellent adhesion properties, due to which you can work with porcelain stoneware or with standard tiles;

- laying can even be done from top to bottom.

Litokol

These adhesive mixtures are produced in Russia and are in demand among many buyers. The company offers cement-based, dispersion and two-component mortars.

The most popular product is Litokol K-80. It has the following advantages:

- high rates of adhesion and plasticity;

- long pot life - indicators exceed seven hours;

- low consumption - no more than 1.5 kg with a layer thickness of 2 mm.

Among the disadvantages are the following:

- small interval for adjustment - the maximum time is 10 minutes;

- low frost resistance - withstands only 30 freezing cycles.

Litoelastic

Glue is in demand, which is sold in buckets of 10 kg. The product is an elastic adhesive that is suitable for external and internal use, as well as for waterproofing rooms with high humidity levels.

You can get a ready-made epoxy mixture by mixing the two ingredients according to the instructions for use.

Ceresit CM-11

The glue is considered universal. It is used when laying ceramic tiles. The cost of the product is about 265 rubles per 25 kg. The product has disadvantages, which lie in the low performance of the glue, so it can be used to work with not every type of tile.

This product is ideal for masonry on uneven substrates. It is characterized by a high level of adhesion, which exceeds 1.0 MPa.

Ivsil Mosaik

The manufacturer offers a moisture resistant quality product. The cost of the mixture is about 480 rubles per 25 kg. White glue with high adhesive properties exceeding 1.0 MPa. It can be used to lay tiles in swimming pools, saunas and showers. The glue is considered professional and is used to work with any surfaces of tiled origin.

"Moment" Silicone sealant

Among the elements of this product are antiseptic components, due to which you can forget about the formation of mold. The product has high adhesion properties to ceramic tiles. Does not lend itself to ultraviolet radiation, is characterized by a pleasant aroma that disappears after application. The cost of such glue varies within 250 rubles.

Litoflex K80

The mixture is classified as professional. The cost of production is about 530 rubles per 25 kg. Designed to work with porcelain stoneware under different installation conditions. The tool allows you to provide masonry on old surfaces, underfloor heating, is used for facing facades and plinths.The mixture can also be applied to regular tiles. The product is economical in consumption.

Bergauf Keramik

The adhesive mixture is characterized by high elasticity, which makes it easy to use. The product can be used for external and internal work. It does not lose its qualities during temperature changes and provides high-quality adhesion.

It is resistant to moisture, so it is often purchased for work in the bathroom, garage and on balconies.

Quick drying saves time.

Among the advantages of the master, the following qualities are distinguished:

- elasticity;

- ease of use;

- resistance to high loads;

- easy stirring of the mixture;

- good work result;

- the product can be applied to warm floors.

Mira 3130 Superfix

The manufacturer offers moisture resistant adhesive mixtures. The cost of production is about 650 rubles per 25 kg. The material can be used when working in wet conditions, when laying "capricious" products.

Benefits include:

- elastic properties;

- waterproof;

- high rates of frost resistance.

Keraflex Maxi

"Keraflex" is considered the most worthy material for laying large tiles. The product is characterized by high adhesion, plasticity and easy use. When working with this material, you do not need to level the base.

How to choose?

When choosing a tile adhesive, you should take into account the specifics of the installation and the type of material used. To purchase the best option, you need to study the composition of the product and the manufacturer's recommendations.

When choosing a tile adhesive, the following skills of the master should be taken into account:

- speed of work;

- experience in this direction.

You also need to decide on the following indicators:

- operating conditions of the glue - the choice is influenced by the presence of temperature extremes, room humidity, the need for antiseptic and antifungal additives;

- the purpose of the glue on the surface - there are universal mixtures, solutions for vertical or horizontal laying;

- the ability to use on a specific substrate - there are options that provide high-quality grip on a rubber, ceramic surface. Some manufacturers offer glue for woodworking or plywood fixing;

- time to adjust styling;

- type of mixture - dry or ready-made options are on sale;

- profitability of products;

- permissible layer - some types of adhesive mixture do not allow leveling tiles without prior leveling the base.

If you will be applying the adhesive in layers of different thicknesses, it is better to foresee this quality in advance.

- versatility in use - can be applied to the base or to the tiles;

- adhesion indicators;

- laying a certain type of tile.

Each manufacturer encloses an application manual with their products, which describes the features of using the product. Detailed technical properties are always found on product packaging.

All adhesive mixtures for working with tiles are divided into two categories:

- specialized formulations;

- universal products.

Many shoppers think it's best to get a generic blend and not waste time researching the packaging. However, experts advise to approach the issue of choice with all responsibility, since universal formulations are not able to provide the maximum result when working with certain materials. Also, the service life of the all-purpose adhesive is shorter than that of specialty mixes.

The glue must be purchased according to its purpose:

- moisture resistant mixtures with antiseptics should be used in rooms with high humidity levels;

- heat-resistant glue is intended for laying heating surfaces;

- frost-resistant options should be purchased for working on an open balcony or in a loggia without heating;

- universal the mixtures are optimal for dry rooms, when working with wall or floor surfaces.

How to breed?

To obtain a good quality adhesive solution, you will need to dilute the mixture in small portions. This method allows you to work slowly and lay the tiles with high quality. Although the proportions are indicated on the packaging, there is no need to blindly follow the written instructions..

First, you need to take 2/3 of the water and mix it with a full portion of the dry mixture. Then you should gradually add the rest of the water until the solution gets the required consistency. Add more liquid if required.

Stirring the glue by hand is difficult, so use a construction mixer. The consistency of the mass is checked with a spatula. The consistency should acquire sufficient elasticity without lumps and spreading. Leave the mixture on for 20 minutes so that all the ingredients are completely swollen and turn into a single mass.

Do not leave the resulting solution for a long time, as it dries quickly.

Useful tips for use

Tips from the masters will help you to competently glue the tiles to the base. With the help of the described recommendations, you will quickly cope with the tasks and will be able to avoid possible mistakes during installation. The work should take into account the condition of the substrate and environmental conditions.

In order for the ceramic coating to firmly adhere to the surface, it is necessary to carefully inspect the base before work. Prepare the surface if necessary.

Recommendations for using tile adhesive:

- It is not necessary to carry out styling in the cold season. Postpone your event until the thermometer rises above 5 degrees. This temperature is considered the minimum for high-quality hardening of cement glue;

- In hot weather, work is also not worth it. Install in a temperature range of 5 to 35 degrees. In extreme cases, you can lower the temperature of the base by wetting the floor and tiles with water;

- Mounting in direct sunlight or windy conditions may reduce performance. If it is impossible to reschedule the laying time, moisten the base with water or use a primer for these purposes;

- If you plan to install on new surfaces, make sure that the base is solid. When gluing tiles to concrete or plaster, wait until the coating dries. Thoroughly clean the substrate from foreign objects and oils that impede adhesion. Irregularities must be corrected with repair mortars;

- When working on an old surface, test it for strength. For this purpose, you will need a regular hammer or construction nails. Crumbling zones should be beaten off to a solid foundation, cracks and chips should be strengthened with a repair mortar. Uneven surfaces and distortions on a horizontal base can be corrected with leveling compounds;

- To ensure good adhesion of the painted surface to ceramic tiles, sand the coating or create small notches;

- When working on absorbent surfaces, which include chipboard, gypsum panels, gypsum blocks and aerated concrete, work should be done to eliminate the absorbency of the base;

For these purposes, primers are used.

- When working with wood, you will need a primer. To prolong the life of the coating, apply with a mesh.

These recommendations will help you to properly fix the tiles on any substrate and reduce the time at work.

For a comparison of tile adhesive from different manufacturers, see the following video.

The comment was sent successfully.