How to cut tiles with a tile cutter?

Tile is one of the oldest ways to decorate a room. Despite this, it is used to this day, taking its rightful place along with modern finishing materials. Thanks to its technical characteristics and beautiful appearance, the tile has become the leader in the market for cladding products. Many people prefer it.

When laying tiles, you cannot do without cutting it., since ceramic tiles are often not suitable for their dimensions. Therefore, in many cases, they are pruned. And without certain knowledge and special tools, this is not so easy to do. If you are not going to lay tiles for professional purposes, then you can save on buying a high-tech tool. So, you can purchase a manual tile cutter.

It is mechanical, easy to use, and much cheaper than electrical.

List of instruments

When working with tiles, you will need the following tools:

- tile cutter;

- marking pen or felt-tip pen;

- a ruler, preferably made of metal;

- manual tile cutter.

Manual tile cutter

Many people use a manual tile cutter when cutting tiles, as this is one of the most convenient options. It is of high quality and inexpensive at the same time.

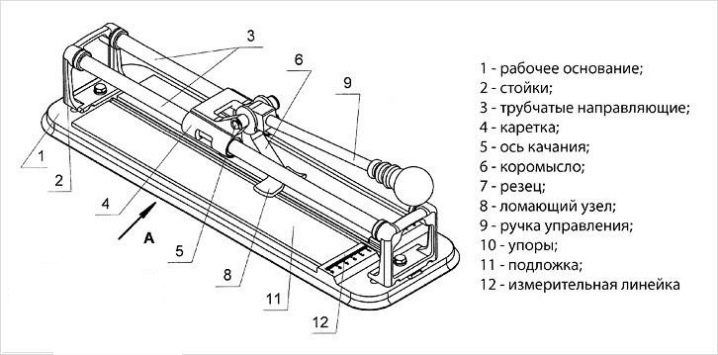

A manual tile cutter consists of the following components:

- support (it is also the basis);

- guiding part of the structure;

- cutting element, consisting of a roller and a cutting disc;

- lever.

The optimality of the option is as follows:

- due to its simplicity of design, it is easy to use;

- the handle that moves the carriage with the cutting disc acts as a lever;

- due to the laws of physics, the cutting effort is reduced;

- allows you to make an accurate cut.

-

But this tool also has its drawbacks:

- such a tile cutter cannot make a cut at a distance of less than 5 mm from the edge of the tile;

- if you want small pieces, about 5-7 mm, you have to be very careful. It is possible that the tile will break.

Safety engineering

When using a tile cutter, it is important to study the safety rules inherent in any such tool:

- before starting work, you should examine the subject, see if there are any breakdowns or other damage;

- the carriage should run smoothly, smoothly and without pushing;

- tubular guides should not contain pieces of tiles, traces of mortar and other debris. After cleaning, they should be lubricated with machine oil;

- the disc for cutting tiles itself should rotate easily around its axis and not contain burrs;

- to avoid injury, it is advisable to use special goggles and protective gloves.

Basics of carving

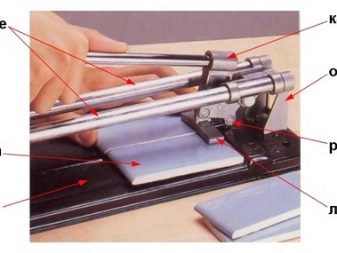

Before you start cutting the tiles, you need to re-check the calculations and draw a strip on the tile. The incision is made along this strip. It is better to draw a line with a marker, so it will not be erased, and you will accurately follow the direction of movement.

We fix the tile, clearly fixing it on the tool. There are designs that have grips with special layers made of rubber. Otherwise, you will have to cut off a piece of the tile (diagonally). Hold the other half with your hand. However, this is not difficult. During the cut, you need to measure the pressure exerted by your hand on the handle.

If you apply too much force, then the decorative layer can easily deteriorate, and if very little, then you will not be able to break the tile. You cannot walk the tool over the tiles twice.

For training purposes, previously broken material can be used. Having fixed it, you need to move the carriage towards you. So you can easily determine the strength of the required pressure. The cut must be made in one motion, otherwise you can damage the decorative part of the tile.

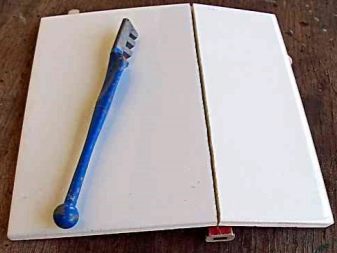

After making the cut, the tiles should be laid on a smooth surface, the cut line should be aligned with the edge of the surface. With one hand, hold the tile on one side of the cut, with the other - press.

If everything is done correctly, then the tile should break exactly along the line. Above it was described how to work correctly with a manual tile cutter, below - we will analyze its electric version.

Electric tile cutter

Not everyone has such an electrical device, and many are interested in how to use it. An electric tile cutter is similar to a circular cutter due to the identical arrangement of the swivel head, motor, support and disc. They are distinguished only by the fact that in a high-quality electric tile cutter there are dishes with water at the bottom. This cools the disc during cutting and reduces dust.

Positive qualities of the electric tile cutter:

- it allows you to make a perfectly straight cut;

- the minimum number of chips formed;

- allows you to cut tiles at a certain angle;

- almost complete absence of dust;

- the possibility of cutting small parts.

There are also disadvantages:

- such a device is quite expensive;

- there is no way to make a curved cut.

Safety rules

We must not forget about safe behavior when working with an electrical appliance.

- work should be done only with special glasses;

- before starting work, you should pay attention to the disc, which must be sharp enough and rotate smoothly;

- if there is an incomprehensible sound or sparks, the equipment should be disconnected from the power supply and taken to a service center;

- check if there is water;

- Cutting can only be started after the disc has reached maximum speed.

Tile cutting

The main feature of the tool is that it is elementary simple. Set so that the disc is guiding exactly along the line drawn for the cut. The tile must be guided by holding it, remembering that the first touch should be light enough. The next step is to apply a little effort while advancing the tile.

If you feed the tiles by hand without fixing them, be sure to ensure that there is no vibration, as chips may form.

Important: In order to increase the operating time of the disc, you should periodically change the water during carving, especially if you have a large number of tiles. When cutting, press on both parts of the tile with equal pressure to avoid skewing.

How to cut tiles without a tile cutter?

During construction work performed with one's own hand, it may often be necessary to cut the tile yourself at home. However, it is not necessary to use a tile cutter for this purpose. If you do not have a large amount of work, then there is no point in purchasing an expensive tool. When working with small batches and piece products, you can also use available tools.

Cut types:

- The incision is made strictly along a straight line. You should also understand where the cut goes. It is considered curly if the distance between the line and the edge is no more than 2 cm.

- Mosaic elements. The curly cut also includes strict forms of geometric shapes. In other cases, you need to crush the tiles into small pieces. All products are put into a bag and, using a heavy tool, are broken to the required size. Non-ceramic tiles are an exception.

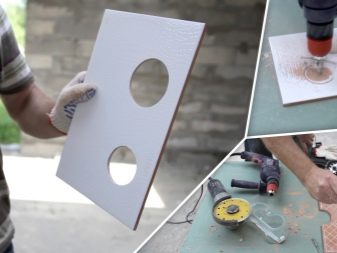

- Round holes with different diameters.

- Curly cutouts.

angle grinder

You can use a grinder if you don't have a tile cutter. It is considered a versatile apparatus. It should be noted that for people with little skills in using this tool, this method is suitable for straight curly shapes, as well as any lines, including curved stripes.

In the process of work you will need:

- Bulgarian;

- special helmet;

- it is advisable to use a respirator;

- diamond circle. You can use a stone cutting wheel;

- mittens and special suit. It must be closed;

- clamping tool. In some cases, a vise may be needed;

- protective glasses.

Jigsaw

Many people underestimate this tool. However, it can be very useful if there is no tile cutter or grinder available. It is worth noting that a stone saw jigsaw can be used in the same way, but the speed of work will decrease several times.

For a cut you will need:

- jigsaw (power does not matter);

- it is recommended to use special glasses to protect the eyes;

- a file for carving on a stone.

Figured breaking

When working with tiles, it can often be necessary to use lines. These lines can be either semicircular or straight. There are often cases when the cut does not start from the edge of the tile, then you have to make a small hole, then a small part is pricked, and breaks off only after that.

To reduce the number of splinters, it is recommended to apply a deep risk along the entire breakout boundary.

To learn how the tile cutter works, see this video.

The comment was sent successfully.