Epoxy grout for tiles: features of choice

The popularity of tiling on various surfaces is due to the high quality characteristics of such a coating. Walls and floors finished with tiles have high environmental, aesthetic, moisture-resistant, wear-resistant qualities. The tiled surface is easy to clean, and you can use a variety of cleaning agents.

But when laying tiles and other similar finishing materials, a splitting is provided between the finishing elements. To protect the tile joints from moisture and dirt, jointing is used. This is a jointing joint. The appearance and strength of the entire coating depends on the quality of the finishing work with grouting.

Peculiarities

The grout fills the joints between the tiles, preventing the destruction of the finishing coating and protecting it from adverse external influences.

Additionally, grout has the following functions:

- Prevents dust, debris from getting under the cladding;

- Fights water penetration, thus preventing mold and mildew from multiplying;

- Hides imperfections and irregularities in masonry;

- Gives strength and tightness to the entire cladding;

- Improves the aesthetic appearance of the finished finish with a variety of colors

Various homogeneous mixtures based on cement and resins are used as grouting materials. Cement grout is a dry or ready-made mixture of Portland cement, polymer plasticizers, sand, modifiers. Cement grout is notable for its reasonable price and ease of use. The main disadvantage of cement-based grouts is their low resistance to aggressive chemicals and water, which leads to rapid wear of the joints.

Resin-based grouting mixtures have high performance characteristics. Epoxy grout is made from two parts. The first composition includes epoxy resin, dye pigments, plasticizer, quartz sand. The second part of the grout comes in the form of an organic catalyst additive for fast curing. Mixing these components allows you to get a ready-made plastic mixture for finishing trowelling.

The variety of color shades allows you to match the grout to the interior and the color of the finishing material. Color fastness throughout the entire period of operation is the main distinguishing feature of epoxy grout.

Epoxy composition is possible for grouting in joints from one millimeter to a couple of centimeters. Manufacturers claim that the service life of the grout is half a century without loss of quality characteristics. The epoxy mixture is applied to the seams of various materials - when finishing with ceramic tiles, natural stone, porcelain stoneware, glass, agglomerate, metal, marble, wood.

Epoxy grout has high performance. After hardening, the seam becomes very strong, it does not lend itself well to mechanical stress. It does not change under the influence of temperature, ultraviolet radiation, water, acids, rust, grease, dirt and household detergents.

The subtlety of using an epoxy mixture is that the grouting surface must be clean, dry, dust-free, without traces of tile glue or cement.

Scope of application

Since the epoxy mixture has increased characteristics of wear resistance and moisture repellency, it is ideal for trowelling in damp areas.The mixture is suitable for outdoor use, in areas of high traffic, in rooms with exposure to aggressive substances.

Often, epoxy grout is used in such cases:

- If the tiles are laid on the underfloor heating system;

- In bathroom;

- In food shops;

- In canteens, cafes;

- In laboratories;

- In production areas;

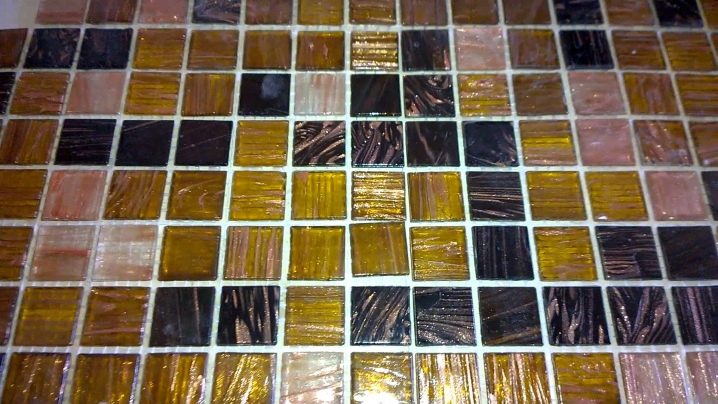

- On a backsplash or mosaic countertop;

- When facing the pool bowl;

- When decorating shower rooms;

- When finishing the floor in the sauna;

- For grouting tiled surfaces outdoors, on a balcony, on a veranda or terrace;

- When facing stair treads;

- For grouting mosaics or art panels.

In whatever case you choose an epoxy grout, it will last a long time, without deteriorating its properties.

Advantages and disadvantages

All building and finishing materials have their pros and cons in their application and operation. To decide on the purchase, it is worth considering the main advantages of using epoxy grout in various rooms.

The main ones are:

- It creates the solidity of the cladding;

- She has a long service life;

- Does not absorb water, absolutely waterproof, drops simply roll off it;

- Not affected by mold;

- Can be used as mosaic adhesive;

- Short curing time;

- Suitable for use on various finishing materials;

- Withstands large temperature fluctuations from -20 to +100;

- Large selection of colors;

- Does not change color over time and when exposed to sunlight;

- Resistance to acids, alkalis, solvents and other aggressive substances;

- Cracks appear on it after drying;

- Possibility of use in interior design solutions

Epoxy grout has excellent performance characteristics.

But there are also disadvantages, the disadvantages include:

- The high cost of finishing material;

- Certain professional skills are required in working with grout;

- You cannot add a color tint yourself, this will change the consistency of the mixture and affect the setting time;

- Difficulty in dismantling.

How to choose?

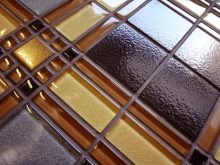

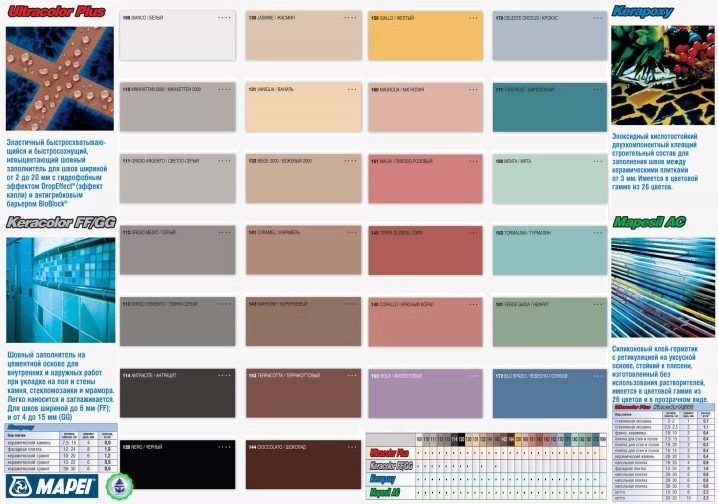

The grout mixture is also called fugue. You need to choose a fugue when the surface cladding is completely ready. The main criterion when choosing a two-component grout is color. There is no absolutely correct solution in the selection of colors, the choice is made individually for each interior, depending on the color of the tile, its shape and size.

For tiled flooring, a light shade fugue is not the best solution. Choose darker, non-staining colors to reduce cleaning time. This applies not only to the floor, but also to other areas with high pollution.

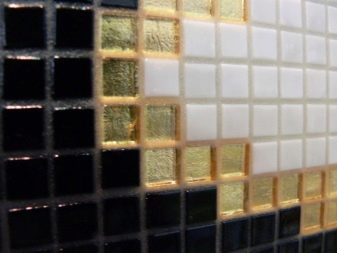

By tradition, for ceramic tiles of any color, the same grout or a similar shade is chosen. When choosing a fugue color for beige tiles, you can choose contrasting combinations. On white tiles, a stylish solution would be gold or black grout. The classic white two-component revetment is suitable for any wall tile color, especially in small spaces

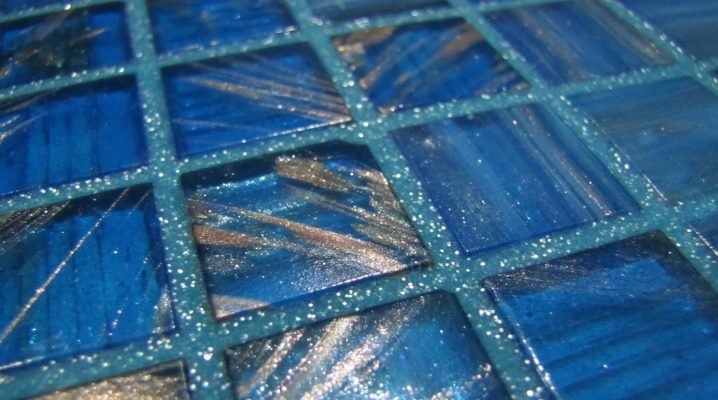

When grouting a mosaic, the color is chosen more carefully. A clear reveal may be needed for artistic design finishes. With the help of special additives made from shiny materials, the epoxy grout acquires various optical effects.

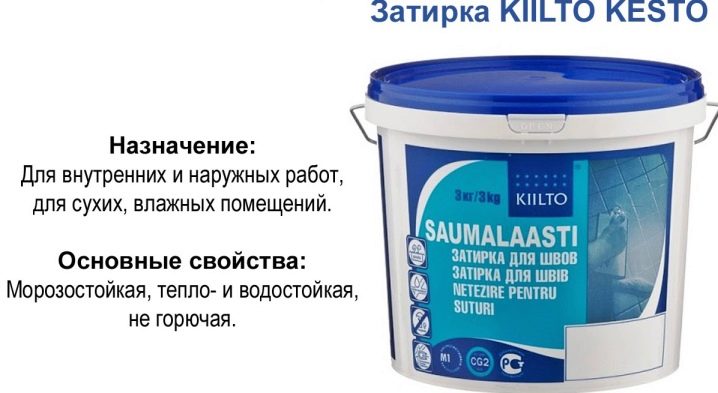

When selecting a grout, it is necessary to first calculate the approximate consumption of the mixture for the entire area in order to acquire the desired weight. You can calculate the volume yourself, knowing the length of the joints, the depth of the tiles and the distance between the elements. You can also use the table of consumption of grout mixtures specified in the instructions. Fugue is sold in packs of 1 kg, 2.5 kg, 5 kg and 10 kg. The weight parameter is especially relevant for epoxy, since it is very expensive.

You also need to pay attention to the indication of the size of the seams. It is always written on the package for what size of joining the grout is suitable.

Without a preliminary study of the technology for forming seams with an epoxy compound, it is difficult to carry out the grouting work with your own hands. For a successful finish, you need to read the instructions for diluting the mixture.

Required tools

After laying the tiles or mosaics, grouting takes place.

For professional and high-quality performance of the work, you will need the following tool:

- Rubber trowel or rubber tipped float to apply grout to ceramic tiles;

- A clean container of the required volume for mixing the mixture;

- Foam sponge for removing streaks and final cleaning of the surface;

- Precise electronic scales for measuring the ratio of components one to nine;

- To form the seams and remove the remains of the grout mixture, use a hard washcloth, a trowel with a cellulose nozzle or a cellulose sponge;

- Capacity for warm water;

- A drill with a mixer attachment, a wooden smooth stick, a piece of plastic pipe or a spatula for mixing the components of the grout mixture;

- A special chemical solution to remove the remaining plaque on the surface;

- Rubber gloves to protect the skin of the hands.

The time of the grouting procedure, the consumption of the epoxy mixture and the solidity of the entire cladding depend on the availability and quality of the tool used. Also, the thoroughness of the final cleaning of the surface with soft sponges and napkins plays a significant role, since it affects the appearance of the finished coating.

How to use?

Epoxy grout is sold in two components. For accurate dosage, the components are measured on a balance in the desired ratio. The proportions for the first and second component in grams are indicated in the instructions for the epoxy composition. The proportions of the components may differ from manufacturer to manufacturer. It is preferable to connect the grout components with an electric drill with a special mixer nozzle at minimum speed. In this case, a minimum amount of air will enter the mixture, the temperature during stirring will remain unchanged. If the proportions are observed, an elastic mixture of the required consistency is obtained.

The term of work with the ready-made diluted mixture is no more than one hour. To avoid hardening in the course of prolonged work, you need to dilute small volumes of the trowel mixture, especially if the worker is rubbing alone or he is a beginner. It is recommended to dilute no more than 300 grams of grout at a time. This nuance will help to completely consume the mixture and avoid the consumption of rejected material. It is possible to increase the speed of finishing work if one person is engaged in grouting, and a second worker will clean the surface.

Wear rubber gloves when diluting and applying grout. If the mixture gets on an unprotected area of the skin, wash immediately with soap and water. It is necessary to work with a fugue at a temperature of at least 12 degrees, since in the cold the solidification time increases and the viscosity changes. This interferes with high-quality rubbing and applying the mixture. Finished seams will take longer to dry.

Seams are filled by applying the epoxy mixture with a trowel or rubber-edged float to a small area. The grout area is chosen so that within 40 minutes of work, the epoxy mixture from the entire grouting area is washed off. The remains of grout are removed with movements along the diagonal of the tile with the soft edge of the trowel.

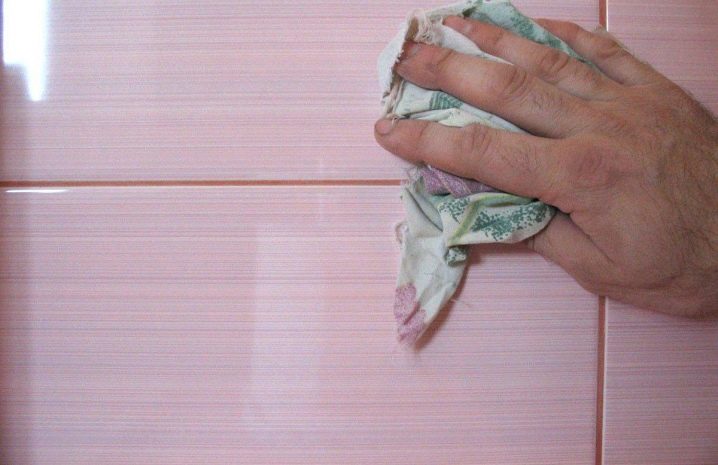

Then, mashing and formation of seams are immediately carried out. Shaping and sanding is necessary in a smooth figure-eight motion to obtain uniform and even trowel joints. Wash off grout residues from tiles with a damp washcloth or cellulose sponge immediately after application, rinsing the material often. Untimely cleaning will lead to solidification of the mixture and deterioration of the appearance of the coating.

The final cleaning is done with a soft sponge in the same way so that the sponge does not wash out or absorb the grout from the joints. The more often the sponge is rinsed in warm water, the faster the cleaning result will be visible.It must be remembered that you cannot enter the adjacent area with a damp sponge, otherwise you will need to dry the untreated area for further grouting. After grouting one area, proceed to the next, thus rubbing the entire facing surface.

The next day, final cleaning is carried out from streaks and traces of epoxy grout. You will need a chemical cleaner that is sprayed over the entire work area. Then rub over the surface with a cloth or clean rag in a circular motion. After the time specified in the instructions, the solution is washed off with a soft foam sponge or microfiber cloth, rinsing thoroughly in warm water. If plaque remains on the surface, then a repeated cleaning procedure is carried out.

The load on the finished surface can be applied in a day. Until then, you must not walk on the tiles and expose the joints to temperature fluctuations. On the fifth day, the seams are completely dry and ready for daily use.

Manufacturers and reviews

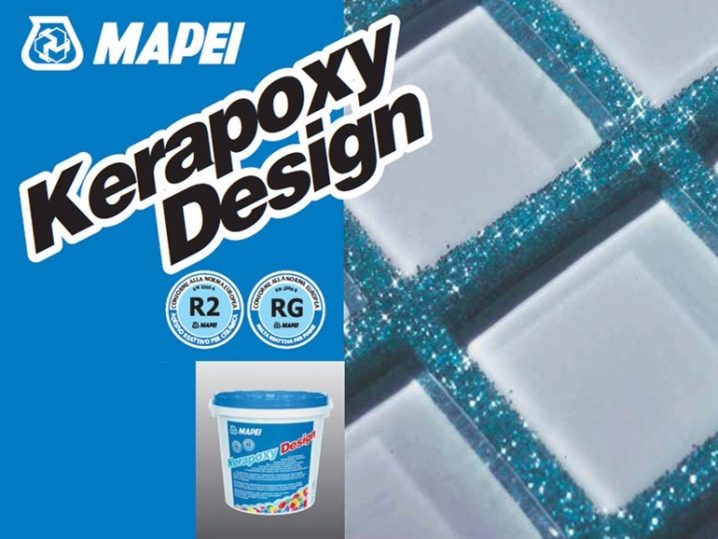

On the construction market, you can find epoxy grouting from different manufacturers. The most popular and widely represented are the products of the European manufacturer Litokol, the Italian company Mapei and the German concern Ceresit. Manufacturers focusing on the production of different grouts offer a wide range of colors and a small price range.

The distinction of the Italian manufacturer is the production of acid-resistant epoxy grout Mapei Kerapoxy. This grout tolerates the effects of aggressive acids, it is used even in the decoration of sewage treatment plants. The line of 26 colors, the readiness of the trowel layer for external influences is three days.

The Litokol company produces 5 lines of grouting mixture, in which there is a wide range of colors - more than 100 shades of epoxy grout, including transparent. They also produce decorative additives with the effect of gold, mother-of-pearl, silver, and phosphor.

According to consumer reviews, epoxy grout in wet rooms fully justifies its use.because it does not form fungus due to moisture. The color does not change, even after cleaning the surface with strong household products, and it is easier to clean, because dirt is not absorbed into the surface. It was also noticed that the Mapei brand grout has a finer-grained structure, smoother in texture. But all grout is slightly rough and rough to the touch depending on the texture.

Buyers leave reviews about the absence of shrinkage of the grout mixture, no cracks and irregularities after the finishing grouting of the joints. Epoxy grout retains its properties on underfloor heating and outdoors. According to people who lay out mosaics and tiles, the epoxy composition of bright colors does not stain porous finishing materials during work. Professionals successfully use epoxy grout as a cellulose-based mosaic adhesive

The main disadvantage of buyers is the high cost of grout, so sometimes you have to make do with cheaper cement material at the expense of quality and durability.

How to work with epoxy grout, see the next video.

The comment was sent successfully.