Underlays for wallpaper: types and features of installation

The walls in the house should not only be beautifully finished, but also fulfill their function - reliable noise and heat insulation. So it's not enough to choose a beautiful wallpaper and think over the design of the room. First you need to prepare the walls themselves. And this is done using a background under the wallpaper. The use of such material will significantly improve living conditions in an apartment or house.

Functions

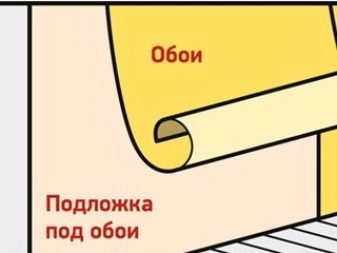

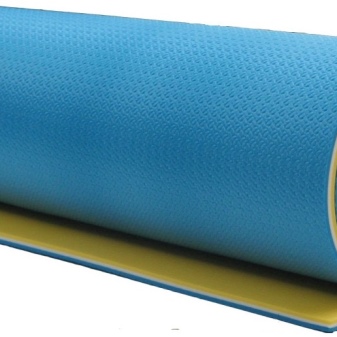

The substrate consists of several layers. In the middle, as a rule, there is polyethylene foam, enclosed between layers of paper.

The underlay for wallpaper is a reliable insulation material, which can be an important advantage in houses or apartments with cold walls.

Many multi-apartment "anthills", both old and new, do not have good sound insulation. Residents hear other people's conversations, and not only in raised tones, music and harsh sounds from neighbors. All this is unnerving and does not allow to live in peace. Sound insulation is just provided by using a backing under the wallpaper. Also, this material allows you to overcome the problem of indoor humidity.

It is an excellent lining for any wallpaper. Using it, the outer decorative layer is easier to glue and will look better on the walls.

The use of underlays allows for maximum adhesion of the finish layer, even in such problem areas as corners and joints.

As a result, the finishing will last longer and the problem of new repairs, as well as the material costs associated with this, will be postponed. Once upon a time, old newspapers were used as a substrate. It was easier to glue wallpaper on them. Since then, technology has gone very far. Taking into account all the possibilities of modern substrates, their use cannot be considered a whim.

Types and composition

The buyer can choose from several varieties of this roll material:

Paper

The base of the backing is paper. Its use is especially useful in cases where it is problematic to get rid of traces of the old finish. It sticks to the wall surface better than wallpaper. Its disadvantage is that it does not hide the obvious flaws of the wall. Moreover, it is precisely such a substrate that is not particularly strong.

Non-woven

Externally similar to non-woven wallpaper, the same durable and easy to stick. At the same time, it is an expensive substrate. Not everyone decides to buy it.

Cork

Created on the basis of technical cork, not decorative, therefore it is cheaper than cork finishing material. Its great advantage is its excellent sound absorption, which is irreplaceable if the house has thin walls and you can hear everything. But you need to mount it competently and using special glue.

Polyethylene

This is a sandwich with polyethylene foam between two layers of paper. This material perfectly masks the imperfections of the wall surface, and thanks to the inner layer it acts as a sound and heat insulator. It turns out to be a kind of improved version of the foam, which is traditionally used to provide silence in the room.

Benefits of using

In addition to the sound and heat insulation function, such a material has many beneficial characteristics. The advantages of using it are already in the fact that it is environmentally friendly and therefore applicable in any home. Most substrates will not absorb liquid. Accordingly, condensation does not form on it, and it will be able to protect the house from fungus for decades.

This coating partially evens out the base on which it is located. Small cracks and chips on the surface can be successfully hidden with this material.

Its properties have not changed for at least twenty years. Some of the manufacturers give it a half-century guarantee. Therefore, once having spent money and time on the purchase and installation of such a substrate, you can make your life easier with subsequent repairs, when you have to change the wallpaper again and again. The soundproofing feature of this material will be especially noticeable where the walls fence off the interior space from the street and common corridors. Good thermal insulation in these cases will also successfully demonstrate itself.

How to glue correctly?

Practice shows that the backing for wallpaper adheres remarkably to concrete, wood, plywood, and drywall. In order to firmly glue it to the surface, it is necessary to prepare the walls themselves for this: tear off the old wallpaper, remove paint residues, level the cavities and seal the cracks with putty or cement mortar. Then you need to prime the surface. For this, PVA glue or some other similar composition will do.

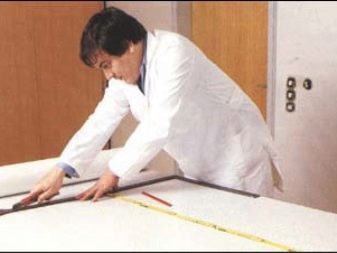

The backing strips themselves need to be prepared for wall sticking in advance. They are cut very easily. They must be divided into canvases taking into account the height of the walls and let these sheets align.

In order for them to have time to straighten out, it is better to cut it out a day before the start of pasting the walls.

Smooth webs of the material are coated on the inside with PVA glue or glue, which is used for heavy wallpaper or under polystyrene. With an increased level of humidity in the room, baguette glue or liquid nails are used. (This, of course, will come out more expensive, but you can be sure of the quality of the repair).

With all this in mind, you need to act so that the glue does not get into the joints. Otherwise, the pieces of the backing will stick together and the seam between them will be uneven. The canvases with the glue applied are left for five to ten minutes, and then glued on the walls side by side - just like most modern wallpaper. In this case, the wall must also be smeared with the same glue before that. Note that if the outer layer of the backing is non-woven, and not paper, then only the wall itself needs to be smeared with glue.

To maximize adhesion to the wall surface, a rubber roller is used, with which all the air is squeezed out from under the substrate and carefully rolled over the wall.

The gaps between the canvases must be sealed with paper tape or paper tape. To avoid disappointing results, as in the case of wallpapering, drafts should be avoided. Experienced people advise to carry out the work at temperatures above +10 degrees and humidity less than 70 percent. If the room is cold, the glue will not set, but if, on the contrary, it is too hot, it will dry very quickly, and you may not have time to fix the entire substrate on the wall. Some areas will not be glued. Taking these features into account, it is recommended not to undertake such repairs in spring or autumn, when there is high humidity and strong temperature drops.

After the job is done, you need to wait two days and only after that start decorating the walls with wallpaper.

Proposals from manufacturers

To choose the right backing for wallpaper, you need to keep in mind the experience of the professionals involved in decorating. On the market there are substrates for wallpaper, both foreign and domestic. They can be found both in building materials stores and specialized wallpaper stores. Different brands of substrates may differ in thickness and material composition. So their cost sometimes varies greatly when compared.

Ekohit, Penohome, Globex, Penolon, Polifom Are the most well-known manufacturers of wallpaper backings. Among all the brands under which such materials are produced, experts single out just "Penolon" and "Polifom" of domestic production."Penolon" has good thermal insulation properties. This is achieved due to the air cells in its structure. The thickness of the material is only 5 millimeters. Roll width - 50 centimeters. A total of 14 meters per roll. At its core, "Penolon" is a chemically crosslinked polymer.

There are several types of such polymers - gas-foamed, not cross-linked, physically and chemically cross-linked. The cheapest of all is non-crosslinked polyethylene. In terms of strength and thermal insulation capabilities, it is 25% worse than physically and chemically crosslinked polymers. The latter two, despite the fact that the technology of their manufacture is different, are very close in their characteristics. "Penolon" is hygienic. It is lightweight and elastic. Resistant to alkali, acid, alcohol and gasoline. Easily spreads out before sticking. Low vapor permeability. Suitable for leveling surfaces, suppresses noise, eliminates the cold coming from the walls, allows high-quality gluing of wallpaper, eliminates the effect of "crying" walls.

"Polyfom" (sometimes it is also called "Polyform") has the same geometric parameters as "Penolon". It is also 14 meters long with a canvas width of 50 centimeters and a thickness of 5 millimeters. It is an environmentally friendly material that does not absorb moisture, prevents the spread of mold and mildew. It is a reliable heat insulator.

When choosing a material experts advise paying attention to the color of the roll - it should be white or light gray. It also matters how firmly the paper layer is attached to the base. A high-quality material is odorless and has a certain elasticity - after pressing with a finger, its surface should quickly return to its shape.

- When choosing a substrate for wallpaper, it is better to focus on the reviews of masters who have already gained experience in handling such materials, know all their pros and cons and how to use them correctly.

- You also need to keep in mind that before using such materials, if there is even the slightest hint of the presence of a fungus, the surface of the wall must be treated with special chemicals. The underlayment must not be used in saunas and bathrooms.

- In rooms where the humidity is high enough, it is preferable not to use paper substrates, since the paper itself does not tolerate dampness well. It is better in these cases to use non-woven or cork products.

- It is better to glue dense wallpaper to the backing, since thin ones can show through, and the bottom layer will be noticeable. If, after all, you chose a thin wallpaper, you need the color of the background to be white. Otherwise, the color of the wallpaper itself will be distorted, and the resulting effect will unpleasantly surprise you.

- If gaps have formed between the canvases glued to the wall, you can mask them with paper adjusted to the size of the slots with the help of glue. The underlay itself does not have an absolute soundproofing function. This effect is achievable only with the use of special materials that require special fastening. Their thickness can reach 15 centimeters.

- A high-quality substrate does not smell, does not emit dust or harmful substances. It is suitable for rooms where allergy sufferers as well as children live.

- The heat-shielding properties of such materials have been tested in practice. These qualities are especially noticeable on cold concrete walls. Experts willingly use substrates for finishing summer cottages and in block houses. This helps to save on heating during the operation of housing and other facilities.

See the next video for more on this.

The comment was sent successfully.