All about files

Despite the availability of a large number of electric tools, some of the hand tools cannot be replaced. A file is one of these devices that can be used for a wide variety of work. Many difficulties arise with the choice of a suitable option, since the classification is carried out according to a variety of criteria.

What it is?

A file is a hand tool, the main purpose of which is to gradually remove material. Every year more and more options appear, some are suitable for working with metal, others with softer materials.

The location of a large number of cutting edges allows for grinding. Similarly, you can perform the following actions.

- Adjust the product to certain parameters. They can be called dimensions, shape, as well as the class of surface roughness. It should be borne in mind that with a file it will be possible to remove only a few millimeters of material.

- Extend the diameter of the inner hole. This procedure is similar to boring, which can only be carried out with a round work surface.

- Shorten the part. The end face is often filed to change the length.

The main body is made of special hard steel. This determines that the work surface is harder than the work surface.

The tool in question is produced in accordance with GOST. If it does not meet the established requirements, the service life is reduced several times.

Modern files are a complex tool that must meet all the requirements. They are as follows:

- the cutting edge should be made of an alloyed alloy that will not rust even at high humidity;

- the hardness indicator is selected depending on which workpiece will be processed;

- the tool must be comfortable, fit well in the hand, otherwise it will be difficult to carry out the work efficiently;

- the working part must have exact dimensions, defects are not allowed.

Files are also available as attachments for electric tools. Their difference lies in the absence of a handle, instead of which a special shank is made, which ensures the required reliability of the connection.

Materials (edit)

All types of files can be classified as cutting tools, which are characterized by the presence of a handle and a working part. The contacting part at the time of work, as a rule, is made of steel. The most widespread is tool steel.

- Grades 13X and SHX15. Alloying increases the basic properties of the metal, for example, strength. Alloying also makes it possible to increase the resistance of the metal to high humidity.

- U13A and U10A are considered improved unalloyed alloys. They are inferior in their properties to alloyed alloys, but are much cheaper.

The surface is treated by hardening. This is done to increase the hardness to 58 HRC. In the manufacture of tools for processing wood or plastic, less hard alloys are used.

Special attention should be paid to the handle. It can also be made from a variety of materials.

- Inexpensive offers are made of plastic. It is characterized by low strength, but at the same time it is light and does not react to high humidity or temperature changes.The disadvantage is that with such a handle, it will not work to transfer a large effort to the working part.

- Wood has been used for many years. It has sufficient strength, but due to environmental influences, it loses its properties over time. Recently, wooden handles are extremely rare.

- Metal handles are the strongest and most durable, can be used to transfer more force. The disadvantages are the increased weight and cost of the tool.

It is the types of materials used that determine the service life of the file, the characteristics of storage conditions and some other points. It is not recommended to buy cheap products that are produced without taking into account GOST standards.

Views

Files can be classified according to a large number of characteristics. The most important feature is the type of notches. This moment determines what kind of work can be carried out, how the layer will be removed from the surface. When making a file tool, they are guided by GOST 1465-59. The notch type allows you to solve a certain range of tasks, there are several options:

- simple;

- transverse or double notched;

- rasp or point;

- arc.

It is difficult to visually distinguish the type of notches, however, it is possible to accurately determine the type by the manufacturer's description or the applied markings. Some varieties are designed for specific tasks.

An additional classification concerns sizes. According to GOST 1465-59, there are 6 numbers.

- Large numbered 0 and 1 used for rough surface treatment. If used correctly, a layer of up to 0.1 mm can be removed in one pass. Cannot be used for precise processing. Rough handling of the tool causes the teeth to chip off the surface.

- When using a tool with notches 2 and 3 more precision can be achieved. In one pass, it removes up to 0.06 mm. A high class of roughness cannot be achieved.

- The finishing pass is carried out with a tool with notches 4 and 5. This option is suitable for finishing the degree of surface roughness, but not for resizing the product.

The above information indicates that a wide variety of applications can be carried out with the file. The tool is unpretentious, but it must be chosen correctly depending on the task at hand.

Single cut

The simplest version with a single cut. A special feature of the procedure for processing soft metals and plastics is the rapid filling of the space between the cutting elements. It is very difficult to clean the grooves.

It is a single notch that allows you to work for a long period. At the same time, there are no serious difficulties with cleaning the surface.

The working part is usually made of a softer, inexpensive metal.

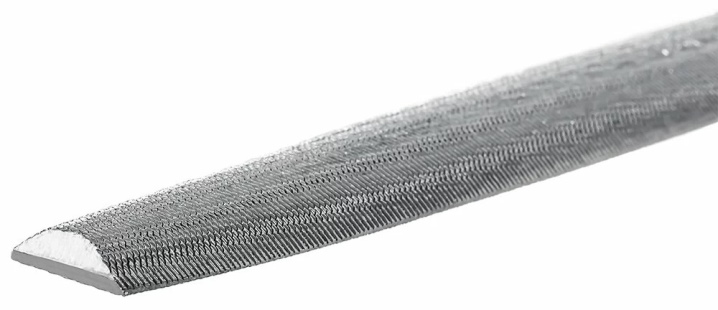

Cross section

The double cut design is effective for working with hard alloys such as cast iron or bronze. This positioning of the cutting edge ensures high productivity.

Chips from hard metal will not clog the furrows. Therefore, the cutting of the surface can be carried out over a long period.

Dot cut

This option is always large. Large notches allow you to work with rubber, wood, leather and other similar materials.

It should be borne in mind that with an increase in the size of the cutting edge, the quality of the processed surface is significantly reduced.

This option is not suitable for a smooth finish.

Types

An instrument can be classified according to a variety of criteria. Metal files are divided into several types.

- Gourmet. There are about 5-12 notches per 10 mm of the working surface. The rough surface is very high with this option. However, as the size of the teeth increases, more material is removed in one pass.

- Personal. This variant, also with a sparse arrangement of teeth and large notches, is suitable for fast processing of a product, changing its shape and size. The number of teeth reaches 25 pieces.

- Velvet. This class is characterized by the fact that there are about 80 teeth per 10 mm. When using it, you need to be careful, too much force can damage the tool.

As a rule, surface treatment is carried out in several stages. To begin with, they use options with large teeth, after - with small ones. The brand often indicates not only the type of material used in the manufacture of the working part, but also the shape.

The most widespread are straightening options. They are cheaper, suitable for most jobs.

A small tool has a large class of accuracy, but large parts take a long time to machine.

Classification can also be carried out according to the shape of the working part - for example, square and tared, rhombic. In a separate group we will include threaded, designed for processing such a surface. The semicircular one looks somewhat unusual, it is used to remove metal from the inner hole. There is a Cape and pneumatic version, which is most often used in factories, the thin one is suitable for removing a small layer of metal.

General

This type of file is the most widely used. Its length is about 50 cm, it is effective when you need to remove up to 1 mm of metal.

The shape can vary significantly. Flat versions are suitable for removing metal from flat surfaces, triangular ones are used for working with internal grooves.

Special

Some parts have complex angles and slopes, a jagged surface. An unusual working part allows you to remove metal from the surface of grooves and grooves.

The sanitary tools are equipped with the largest teeth. Low accuracy determines the possibility of using a file at the initial stage of work.

Needle files

The smallest files are called file files. They are small and precise, suitable for resizing or roughing surfaces.

In the manufacture of needle files, steel grade U12 or U12A is used. Due to additional heat treatment, a hardness value of 60 HRC is achieved. The shape of the working surface is significantly different, it is selected depending on the task at hand.

Rasps

Rasps are widely used when working with soft metals such as aluminum. The working rod is a cast product made of U7A or U10A alloy, surface hardness - no more than 40 HRC. Standard length is no more than 35 cm.

Rasps of various shapes are made. The flat type can have a sharp or blunt tip; round and semicircular shapes can be included in a separate group.

Forms

Another, no less important classification, concerns the shape of the working surface. It is selected depending on the characteristics of the processed product. The following varieties are distinguished.

- Flat received the most widespread use, as they are intended for the treatment of ordinary surfaces, for example, tiles.

- Round suitable for working with internal holes. The working part is made in the form of a rod, which tapers from the end surface.

- Semicircular can be called the most versatile offer.

- Triangular used to work with grooves and edges. The resulting edge has teeth that process the surface.

- Square allow you to apply more force, since the working part retains the required rigidity even during prolonged work.

- Special produced for processing certain products, may have a specific working part.

- Hacksaw can be used for sharpening products.

- Diamond-shaped are designed to work with complex edges.

The shape determines which surface can be machined.

Appointment

The classification of the instrument is carried out according to its purpose. There are several different modifications.

- The metal version is the most widespread. Despite the advent of the electric tool, finishing can often only be done with a file.

- Wood files are also available for sale. They can be used to change the shape and size of the product, they are characterized by a low hardness of the working surface.

- The plastic options are cheap, with a cutting edge of less than 30 HRC.

- The tool for filing cast iron has increased hardness. This is due to the fact that such an alloy is difficult to machine.

- Ceramic files are very common lately. Ceramic products are characterized by high surface hardness, therefore only special tools are suitable for processing.

- Files are rarely used for sharpening, but you can still do this kind of work.

- Drill or screwdriver attachments. To improve labor efficiency, it can be partially automated. Special attachments have a specific attachment.

It is advisable to use each type only for its intended purpose. Otherwise, the tool will wear out quickly, and the goal will be difficult to achieve. For example, you do not need to use the pottery version to handle a shovel.

Hardness

The hardness index largely depends on the type of material used. At the same time, additional heat treatment can significantly increase the indicator. Rockwell hardness is indicated. Files must be selected correctly not only in size, shape, but also in terms of hardness. Basic recommendations.

- To increase the hardness, heat treatment is carried out, which significantly increases the cost of the product.

- Too little hardness becomes the reason why the working surface will wear out quickly.

- The hardness is selected depending on what material will be processed. For rubber, plastic and wood, the indicator can be no higher than 40 HRC. For cast iron or hardened steel, a tool with a working surface hardness of about 60 HRC is suitable.

This indicator is indicated in the labeling. Hardening should be carried out in accordance with the recommendations, as such a procedure can increase the brittleness.

Manufacturers

An important factor when choosing is the company that produces the tool. As a rule, offers from foreign companies are more popular. However, they are much more expensive.

The tool of Russian origin is cheaper. The production is carried out by the company Santool and "Intek", PJSC "Metallist". In any case, when choosing a file, attention must be paid to ensure that it meets GOST standards.

A file can be considered an almost indispensable tool. However, the above information indicates that whole sets should be purchased. This is due to the lack of a one-size-fits-all solution. After buying a tool, you should also take into account the recommendations for care, since if they are not followed, after a few processing cycles you will have to buy a new one.

The comment was sent successfully.