Features of round files

With the help of a file, the master manually shapes the parts into the desired shape. This tool is indispensable where it is difficult or not initially justified to approach mechanical grinding tools.

Description and purpose

The file is used for finishing, precise processing of parts and workpieces made of metal, wood and plastic. It removes the top layer of material from which the part or component is fabricated. The device and the principle of operation are familiar even to schoolchildren: it is a bar or rod with a length of 200, 250 or 300 mm. Its width is most often 2, 4 or 5 cm. It is perfectly flat on all sides, has a rough surface, like coarse-grained sandpaper. The section of the working part can be round, square or rectangular. As a basis, they use special tool steel of the "ShKh15" and "U10A" brands.

Numerous notches, grinding the surface, similar to the grains of a composite material (corundum, fiberglass). An abrasive sandpaper medium is made of them. These are microscopic cutting edges. They form a reefed surface that grinds off materials softer than the one from which the file is made. The steel of the file copes with most industrial steels because it is fast cutting. Its Rockwell hardness is 59.

The handle is the part of the instrument that the user holds onto it. It can be either wooden or rubberized, plastic or composite, and its length starts from 8 cm. The shank of the working part of the file is pressed into the handle, which makes it possible to work with a file with relative comfort. A broken handle is not a reason to part with a tool: it is repairable.

There are times when a broken file sharpening bar does not make it unusable: with the help of a grinder or a saw machine, the fracture point is sharpened. The tool can be used for smaller and more delicate work, where the special scope and speed of the reciprocating movements do not play a role: for example, when sharpening the point of a compass, a blunt nail, a folding knife, etc. then you get two smaller tools instead of one large one.

The file can serve as a miniature saw: the sides, for example, from 3 mm wide, contain notches, like the base. The tool will not replace a hacksaw or power saws. To saw them in the literal sense would be ineffective. The end of the device can also be provided with notches, but most often it is smooth. The shank is not serrated or has a stepped-ribbed surface that allows it to be held securely.

In addition to fitting parts, they remove rust or scale from steel with a file. A file sharpens tools such as a table knife. The parts are sanded with a fine-grained file to a matt sheen. A narrow and thin file is suitable for correcting a worn slot, cutting shallow and small grooves, tracing a radius on the workpiece, tracing glass no worse than a glass cutter. The holes are brought to the required diameter using a round file.

Files are manufactured in accordance with GOST No. 1465-1980. The metal base and the working part of the tool must have hardness and strength acceptable for long and effective work.

Before mounting the handle, the files are tempered in a non-tempering mode.

Species overview

The file is made in the form of a strip of steel with notched teeth, fixed in a wooden or plastic handle. In terms of grain size, the notch has a different size, the license plate of which is indicated on the tool itself: the large one belongs to zero, the smallest belongs to the "five". Number classification divides files into three distinct categories.

- Coarse: up to 12 hooks per square centimeter. Easily remove thick rust and oxide layers from steel and non-ferrous metals.

- Personal and semi-personal: the number of chipping reaches 44. They process any metal or alloy in a rough way, removing its main layer, which interferes with the fit of the part.

- Velvet: 85 hooks per square centimeter. Suitable for grinding parts. After processing, those become smoother.

Fine-grip tools can easily be hammered in with scraped metal, plastic or wood chips. If it is not cleaned, it will become impossible to remove the processed material layer by layer. The speed of work with a fine-grained file is ten times lower than with a coarse-grained file.

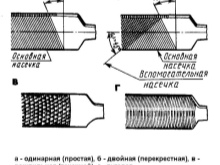

The cut of the tool is presented in several types.

- Single. Non-ferrous metal products are sharpened with it. It sharpens quickly and is easy to clean. The disadvantage is vibration, from which the hands get tired faster during work. The hooks are angled up to 30 degrees.

- Cruciform The notch is suitable for sharpening and cleaning steel, cast iron and bronze. The main notch is inclined 25 degrees, the additional one - 45 degrees. The hooks are crossed, making the structure of the working part diamond-shaped. It is easy to clog the file with particles of scraped off material, and non-ferrous metal is more difficult to pull out of it than carbide chips. Clean the instrument with a steel brush.

- Arcuate the structure of the hooks leaves a neat scratch without torn edges. These processing marks can be easily smoothed out. The product is recommended for processing wood and non-ferrous metals.

- Rasp the notch is the upward-pointing point hooks. It is used to quickly remove rust or scale on steel and cast iron. Also suitable for wood.

- Stamped the hooks are at a certain angle. They resemble hooks. The work is accompanied by the appearance of rough grooves, undesirable on metal parts. Purpose - wood elements and components. The fact is that it is difficult to remove aluminum shavings from such a "bristle".

According to their shape, files are divided into several varieties: round, square, flat, diamond-shaped and triangular. The flat tool allows a large surface area to be machined, and when one side is hammered, it is turned over. for square, diamond and triangular, the scrubbing structure is applied to all sides of the working part. Their length is up to half a meter. Round ones have a notch around the entire circumference and are most often used as a chisel. Semicircular ones do not violate the dimensions of the cut due to its displacement from the required line. The triangular tool is used for finishing the inner edges of cuts that were not initially rectangular.

Selection Tips

Recommendations for choosing a file are as follows.

- Examine the product: its handle should not be cracked or defective. The working part cleaning the material will be homogeneous, without defects. The edges are straight and parallel-perpendicular to each other or converging at the angle required for a particular product.

- Steel is magnetic, and if it is not, then in front of you, perhaps, a fake. A magnet for checking steel products for authenticity can be removed from any equipment and electronics where it is, for example, from the speakers of an old speaker. Stainless steel files are not produced: stainless steel does not magnetise, but for the manufacturer it is a luxury.

- You can sharpen something with a file only after you buy it. No seller will open the packaging as it is sealed.However, it is possible to prove that you are facing a fake if, in the presence of the seller, the purchased tool begins to quickly lose its hooks, turning, when sharpening the test part, into a smooth rod or strip of metal, which is completely useless in the future.

Work rules

Let's consider a few useful rules for operating files.

- Do not use the file as a power lever. There are other tools for this, for example, a nail hammer, a pry bar, a bayonet shovel, as well as steel profiles and reinforcing rods, pieces of pipe, etc.

- Try the file on steel or bronze, if appropriate. Focus on the type of product: the factory packaging indicates what it is intended for.

- Do not use a file for wood and non-ferrous metal for processing steel and cast iron.

- Do not attempt to file a winder drill or diamond blade. Hardened steel can't handle them. Only a diamond (a diamond-coated bar or disc) will sharpen the victorious tip and only when cooled with a liquid. An alternative is a file with the same coating.

- A bindery and soft metal needs to be coated with chalk before work: this way the shavings are much easier to pour out of the notches. The file clogged with particles is washed with kerosene or gasoline.

- The round file from which the handle has been lost can be clamped in the drill chuck and used as a rotating sharpener, allowing you to quickly bring the hole to the desired diameter without centering it.

The comment was sent successfully.