All about marble chips for facades

Marble chips for facades are a popular design solution that allows you to add respectability and chic to a building. Material consumption per 1 m2 is low, you can use different methods of using natural stone additives. The choice of facade paint, plaster or ready-made panels is a matter for the homeowner himself, but some recommendations for textured finishing of houses with acrylic and marble chips should be taken into account before starting work.

Peculiarities

The exterior walls of the house shape its appearance, in many ways set the tone for the landscape design, and emphasize the architectural merits of the building. No wonder that owners of suburban real estate try to choose the most attractive and original decor options for their mansions and cottages.

Marble chips for the facade of a building can be a good alternative to conventional facing bricks, plaster or paint.

It is practical, does not require complex maintenance, and is presented in a wide range of colors and shades. Retaining the properties of natural stone, such a finish is much lighter, easy to install and gives an original look to even the simplest architectural solutions.

Marble chips are a by-product of the processing of natural materials. It looks like uneven granules with a diameter of 2.5-5 mm or 5-10 mm when it comes to raw materials for finishing the basement. This size allows you to ensure the texture of the surface, the decor of the walls becomes voluminous and embossed. Of course, the appearance of the facade will differ from the monolithic marble, but this does not negate the originality of the finish and its other advantages.

A number of obvious advantages of using marble chips can be noted.

- High strength. The coating interspersed with natural stone is resistant to wear. It is not afraid of mechanical damage.

- Protection from the effects of atmospheric factors. The coating does not lose color under the influence of sunlight, is protected from rain, wind, and retains its original geometry when the air temperature changes.

- Compatible with different types of materials. Finishing can be applied to brick, stone, concrete, and other types of walls.

- Water vapor permeability. Walls covered with stone chips allow air to pass through. Mold and mildew do not appear under the finishing.

- Ease of care. The material does not require special attention; in case of damage, the wall surface can be easily restored without dismantling the entire facade finish.

- Ability to eliminate defects. Wall decoration easily hides possible irregularities, which, with other types of decoration, require complex and time-consuming work to eliminate.

There are also disadvantages. Among them is the ability of finishes based on marble chips in contact with metal parts to provoke their corrosion. The filler consumption is also quite significant, especially when carrying out plastering work - up to 4.5 kg per 1 m2. When it comes to painting or applying a thin layer of material, this figure can be reduced to 2.5 kg / m2.

Finishing options

The textured cladding of the facade of the building with marble chips can be performed in different techniques. Most often, special paint or acrylic-based plaster is used, which allows you to quickly cover the house with decorative finishes.

It is not necessary to carry out work with thick compositions on a mesh - it is permissible that the surface of the wall is not perfectly flat and smooth.

Facade decoration based on marble chips for outdoor use has rather large fractions, emphasizing the natural origin of the filler.

And also in the decoration can be used decorative modules, fixed with an adhesive method or dowels. Thermal façade panels are easy to install, look attractive, and can be easily replaced if damaged. In addition, such a layer provides additional noise insulation, suitable for use with insulation. A more detailed study of each of them will help to make the final decision when choosing a finishing method.

Dye

Decorating with paint with a filler in the form of marble chips makes it possible to finish the exterior walls of a building most easily and quickly. Such materials are produced by many manufacturers, including the domestic brand Imperial. Acrylic base ensures fast drying of the coating. Painting can be done on stone, brick, concrete, with or without preliminary tinting. Average material consumption is 0.7-1 l per 1 m2.

When using paint with marble chips, the coating turns out to be matte, rough, but at the same time it can be washed with plain water. The paint is applied in several layers with intermediate drying in 1 hour. Complete hardening of the composition on the facade occurs after 24 hours. This finish is considered universal, it is recommended for use not only on the outer walls of buildings, but also inside public spaces.

Plaster

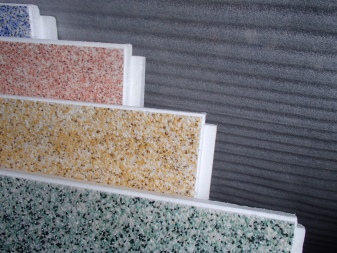

Facade plaster with the addition of marble chips has gained popularity among designers and private homeowners. Natural stone granules in this case act as a filler in addition to a binder and water or other types of bases. Most often, this type of plaster is made on an acrylic base, it can have an additional moisture-proof coating to protect it from atmospheric factors.

On the packaging of facade mixtures with marble chips in the composition, manufacturers must indicate the size of the fractions.

The composition is applied in a continuous layer, in mosaic or according to a certain pattern.

For example, you can highlight the protruding elements of the building structure with a contrasting shade. Consider the algorithm for applying this type of facade plaster.

- Preparation. The facade is cleaned of old coating, dirt, dust. Irregularities, chips, and other defects are repaired with cement mortar. The walls should be dried to a moisture content of no more than 5%.

- Primer application. A deep penetrating acrylic compound is used. It can be applied with a paint roller or brush. The procedure is repeated twice. The surface is dried.

- Tinting of plaster. If the mixture is colored, it is prepared in one tone with the volume necessary to cover the entire wall. This will avoid color divergence in the seam area.

- Plastering. All work must be carried out in 1 reception without postponing for other days. To apply the mixture, a spatula with a length of at least 350 mm is used. The composition is rubbed into the wall, evenly distributed over its surface. It is important to control the thickness of the layer, the adhesion of the material.

- Grating. This metal tool is used only after the main part of the work has been completed. The wall is allowed to dry and rubbed, removing defects.

Plastering of building facades with compositions based on marble chips is quick, allows you to get a good result with minimal effort.

Panels

Facade thermal panels with marble chips combine the advantages of natural stone and heat-insulating materials. The finished slabs are 30-100 mm thick and include a layer of polystyrene or mineral wool. Thermal panels can be used to immediately insulate and decorate the facade. Each product weighs no more than 2.5 kg, fastening is possible both by glue method and by means of dowels.

The production of finishing boards is carried out using an acrylic base.

The modules retain good vapor permeability and remain interchangeable during repairs.

The color scheme depends on the raw materials, most often options are used for clinker masonry, antique, marble or monochromatic.

Installation of panels is carried out on concrete, brick, block walls. The easiest way to do it is by the glue method. In this case, it is not necessary to pre-level the surface, the coating can be mounted in a short time.

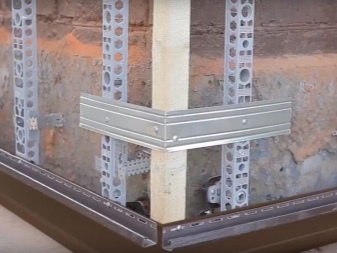

The order of work includes several steps.

- Surface marking and panel cutting to size.

- Fastening the starting profile. It is fixed at the edge above the plinth with anchors. When installing the first row of boards, it is covered with polyurethane foam.

- Fixation of thermal panels. It is carried out from the bottom corner, applying a thin layer of glue with a notched trowel. The second row is mounted above the first, observing the geometry and proportionality of the seams. Each new row is leveled.

It is also possible to fix marble chips coated thermal panels using disc dowels. The choice of material should be made taking into account the type of wall surfaces: for porous (aerated concrete, foam concrete), it is better to take slabs with a mineral wool base. For monolithic and brick insulation, insulation with expanded polystyrene is suitable.

Beautiful examples

The photo gallery presents options for facades using marble chips.

- Contrasting finishing of the facade with marble chips. Darker edging of the corners, the transition to the plinth give the building with laconic architecture originality.

- The combination of brick panels and marble chips gives a special charm to the facade of the house. Shades of finishing materials are harmoniously selected and "do not argue" with each other.

- Partial finishing of the facade and terrace of the house with marble chips effectively combined with modern architectural elements and panoramic windows. Garden furniture looks good against a colorful background.

For marble chips for facades, see below.

The comment was sent successfully.