How are variators for a motorized towing vehicle arranged and how to set them up?

According to some users, motorized towing vehicles with CVTs function better than an automatic transmission. This mechanism has been produced since 2000, so a large number of its manufacturers are known.

What it is?

The variator for a motorized towing vehicle is a mechanism that is necessary for the automatic stepless V-belt transmission of the unit... Most of them are not universal, as they are made for a specific model of equipment.

The use of the variator is aimed at the most smooth speed control. It can be used not only on a motorized towing vehicle, but also on a snowmobile.

This type of V-belt transmission adjusts the gear ratio in accordance with the following parameters:

- resistance to movement of a motorized dog;

- the frequency of rotation of the crankshaft in the engine of technology.

Engines that are equipped with a variator are characterized by slow wear due to the absence of a change in the motor speed.

Device and principle of operation

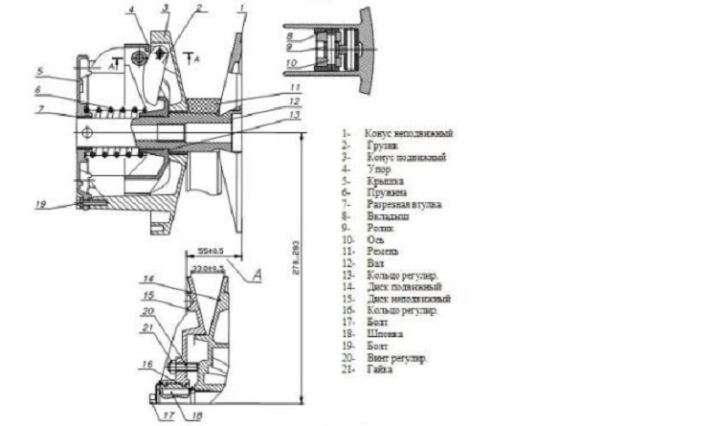

After purchasing a variator for a motorized towing vehicle it is recommended to carefully read the instructions. Having studied the correct operation, you can extend the service life of your motor vehicles. The mechanism includes a centrifugal-type regulator, in which there are cones with moving and stationary weights. In order for the weights to move, stops with rollers are used during their production. Also in the design of the mechanism there are a cover and a spring.

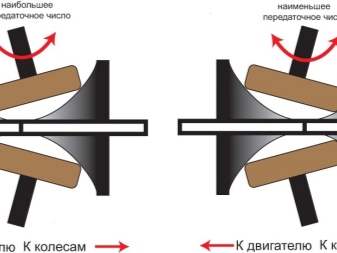

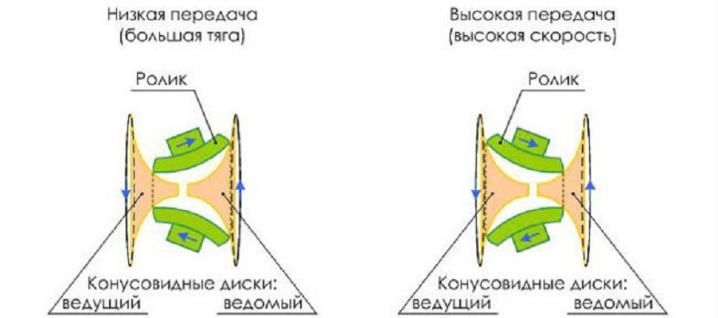

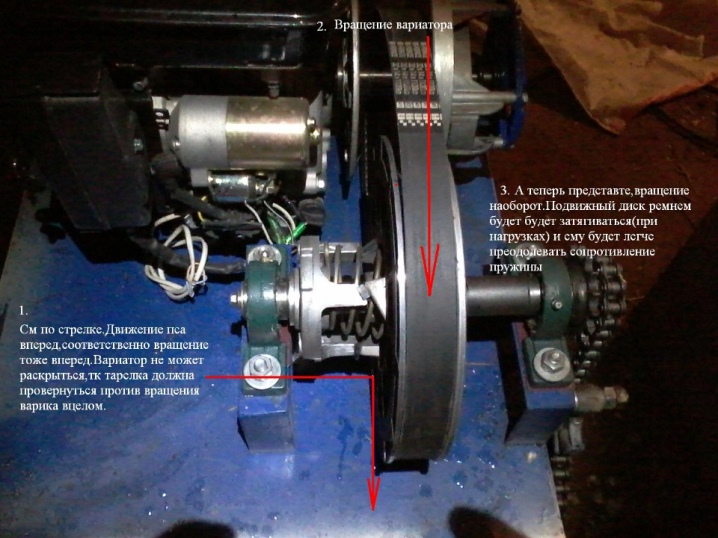

The fixed cone, which has a stop, is threaded to the shaft. The crankshaft is mounted to a fixed cone. The spring is needed to create idle speed. When properly installed, the location of the variator belt should be fixed 1-3 millimeters from the surface of the cone. This option helps to adjust the idle speed. To change the gap, rings are used, which are located on the border of the shaft stop and the protrusion. In the operation of the variator, a certain algorithm is traced:

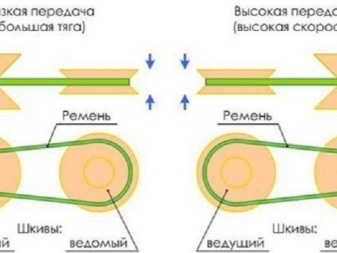

- the regulator rotates;

- centrifugal forces arise;

- centrifugal forces affect the weights.

The effect of centrifugal force promotes the rotation of the weights, so the movable cone is separated from the stop.

The above actions contribute to the belt compression of the pulley groove in the variator. The return spring counteracts the centrifugal force. For this reason, weights can easily overcome opposition. The number of revolutions per minute must be at least 2200. When this threshold is exceeded, the force acting on the belt rises to the working reading. With these factors, torque arises, and resistance is overpowered.

Popular brands

A set of mechanisms and equipment for motorized towing vehicles and snowmobiles is sold under different brands. The Safari variator is popular, it changes the gear ratio and subsequently smoothly adjusts the vehicle speed. This mechanism is also used for installation on a utility snowmobile, for example, "Buran" or "Taigu"... This type of variator has a reinforced crosspiece, as well as a high-quality pressing mechanism. These two components contribute to the overall reliability of the product.

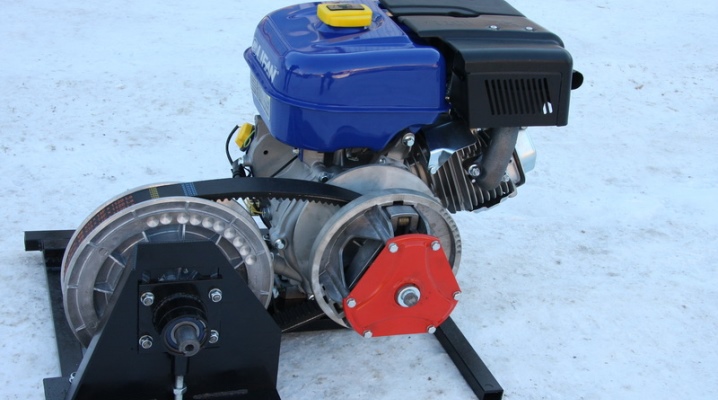

The Safari is lightweight, has a simple design, and is characterized by good reliability. With a mass of 3800 grams, the diameter of the movement is 21 centimeters, and the length is 16.7 centimeters. The variator for the snowmobile and the Forward towing vehicle is also in demand among consumers. This mechanism is characterized by high quality construction, durability and reliability.

How to install and configure?

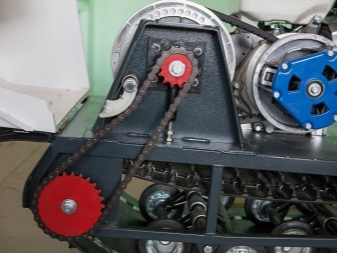

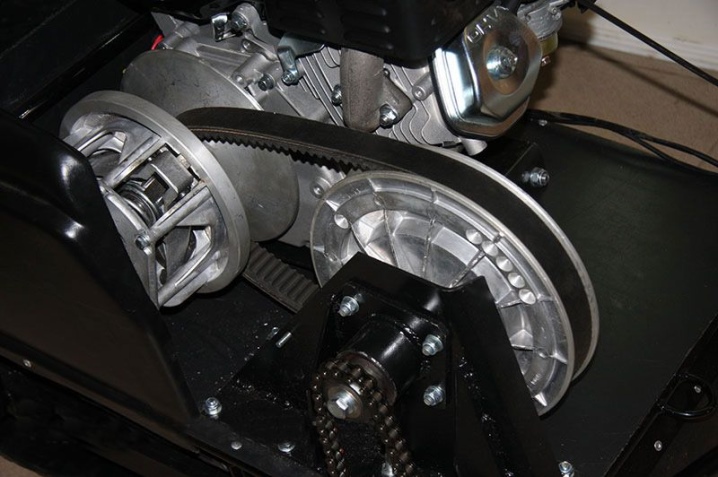

Adjustment and adjustment of the belt, as well as its installation on a motorized dog, should be carried out according to the instructions from the manufacturer. If the user wants to independently correctly adjust and set the center distance, spring preload, follower shaft, then he must follow the technology and safety rules. In order to install the structure, you will need to attach the pulley to the engine crankshaft, while sliding the movable cone.

As a result, a certain hole should be formed with a knob inserted into it. After that, the structure is tightened.

The belt and guard must also be installed according to the instructions. If there is a need to remove the pulley, the dismantling of its shank begins from the crankshaft. After that, the belt and the casing are removed, the movable cone is shifted. With the help of a spacer, the cone is locked, the crankshaft is fixed. Using a wrench, the shaft can be removed. For correct adjustment of the variator, the installation of the mechanism must be completely finished. The distance between the driven pulley and the tapered edges should be 3, 3 centimeters. When the belt is inserted into the groove of the pulley, the sides should not protrude more than 2 millimeters. This adjustment can be considered correct.

Service

Like any other component in the design of a motorized towing vehicle, the variator requires maintenance.... It should be carried out every 3000 kilometers of vehicle run. The owner of the car should not forget about the variator lubrication. It is worth lubricating the parts special universal remedy. After the equipment has passed 6,000 kilometers, it will be necessary to check the condition of the liners on the weight axles. It is necessary to warm up the engine in neutral position, this helps to prevent rubber winding on the shaft. Rubber deposits on the shaft can be removed with a piece of cloth soaked in gasoline.

Possible malfunctions

Any equipment and its elements fail, the variator is no exception. When using this device, you may notice the following problems.

- Uneven movement of the motorized towing vehicle, the presence of extraneous sounds during operation. The reason for this situation may be a worn-out CVT belt or wear of its plastic inserts. To eliminate the problem, you will need to replace the belt or inserts.

- Spreading metal hum may indicate bearing damage.... To correct the problem, the bearings will need to be replaced.

- With the development of engine speed, no movement of the motorized towing vehicle is observed. In this case, it is worth checking whether the belt is torn, whether the track roller has turned over from mechanical damage. Correcting the problem involves replacing the belt and returning the roller to its original position.

- Jamming of the variator during overheating. Worn bushing or belt slippage can cause this trouble. In order for the variator not to jam the bushing, you need to check the belt, clean the discs.

Many owners of motorized towing vehicles say that the variator is a necessary element of it.

In order for it to function without problems, you will need to follow the maintenance recommendations.

How to set up the variator on a motorized towing vehicle, see below.

The comment was sent successfully.