How to choose and install the cutters on the walk-behind tractor?

The choice of milling cutters for a walk-behind tractor is a responsible process, because this element plays an important role in the process of ensuring the efficiency of the device. In order to choose the right cutters, you need to understand the distinctive features of these products, understand what types and types of cutters exist.

The importance of making the right choice

Many novice summer residents think that the most important thing is to purchase a high-quality walk-behind tractor, but they do not pay due attention to the choice of cutters. Such a mistake can be costly when processing the territory, since the correct choice of cutters affects the following points.

- Cultivation quality. If you purchase and use high-quality cutters, you can even do without a plow.

- Saving time. Good milling cutters allow you to spend a minimum amount of time on certain work on the processing of a summer cottage.

- The cutters provide easy control of the walk-behind tractor. An incorrectly selected part can cause increased stress on the operator during the milling process.

In addition, bad milling cutters can put an increased load on the gearbox of the walk-behind tractor, which will negatively affect its durability and performance. It is necessary to choose such elements based on many factors, including the power and type of soil to be treated.

Carefully study the features of your walk-behind tractor, since the following are important: the cotter pin-stopper of the wheel, trailed, PTO or rotary machine, as well as other points.

Factory cutters

Such rotary tillers are considered one of the most popular and demanded on the market. It is with these varieties that factory walk-behind tractors are equipped. Depending on their purpose and design, these cutters can be assembled and disassembled. In the process of choosing, a person decides for himself which walk-behind tractor he needs, but choosing a certain type of cutter will not work. If the equipment was originally equipped with an assembled version, then in the future it will be possible to use exclusively such models.

The design of the cutter may vary depending on the manufacturer and other features. It usually includes a pair of sections that are bolted together. The cultivation width, which can vary depending on the addition of sections, is of great importance in the operation of such an element.

A distinctive feature of the factory cutter is that it is offered complete with a walk-behind tractor. It will be enough for standard tasks. But it should be borne in mind that rotary tillers from a Chinese walk-behind tractor cannot boast of impressive efficiency. If low-quality metal was used in the production process, then problems will arise already during the first processing.

For example, when processing a virgin area, it will be extremely difficult for the user to control the walk-behind tractor. In addition, this will lead to an increase in the load on the gearbox, which will also negatively affect the durability of the device.

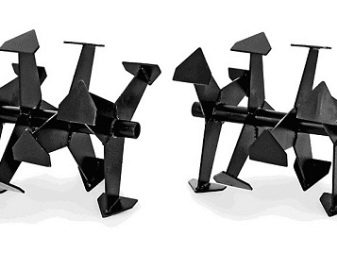

Crow's feet

Hound's feet cutters are considered one of the most demanded on the market due to their high quality and reliability. The main disadvantage of such cutters is considered to be their non-separable design, which makes it impossible to carry out repairs in case of failure.However, if you choose a high-quality option, then it will be able to serve for many years, fully fulfilling its obligations. Among the main advantages of using such cutters are the following.

- The ability to decide for yourself how many sections of the plate can be put on the walk-behind tractor. However, it is important to take into account the technical features of the device and the required milling width.

- A robust design that allows the walk-behind tractor to be used for processing hard soils.

- It copes much better with plant residues.

- A unique bushing that can be of several shapes. Hexagonal and round options are considered optimal. This allows you to choose the right option for any walk-behind tractor, regardless of its type and other indicators.

- Reduces the load on the gearbox, which prevents the device from overheating and has a positive effect on the durability of the equipment.

- It greatly simplifies the process of controlling the walk-behind tractor.

Most experts say that this particular type of cutter is best suited for walk-behind tractors that differ in an air cooling system.

Saber models

Such elements are considered very durable and reliable due to the fact that only steel is used in the production process. In addition, such models boast a unique design that makes them resistant to any mechanical damage. Saber-shaped models are included in the standard set of most motoblocks of European and American production. The effectiveness of such elements has been tested on plots with any kind of soil, which favorably distinguishes them against the background of other models. These cutters are of high quality and high durability, which allows for high-quality soil cultivation.

The main feature of saber knives is that carbon steel is used for the manufacture of working bodies, which guarantees the reliability of every detail even after a year of active operation. In addition, the knives are specially treated and hardened using high-frequency currents, making them incredibly durable.

"Celina"

Another popular type of milling cutter for a walk-behind tractor is "virgin soil", which is in great demand due to its spiral shape. A distinctive feature of this species is its one-piece design, which allows it to cope with even colossal loads without problems.

The main disadvantage is the slow operation, as well as the fact that the soil is pushed out during the tillage process, as a result of which small holes sometimes appear.

As for the advantages, there are a huge number of them, among which the following can be distinguished:

- unlike other types of milling cutters for a walk-behind tractor, it copes well with virgin soil;

- characterized by an impressive depth of cultivation;

- allows you to process the soil with high quality;

- it is distinguished by a monolithic structure, which is a sign of reliability, strength and durability.

Installing the cutter

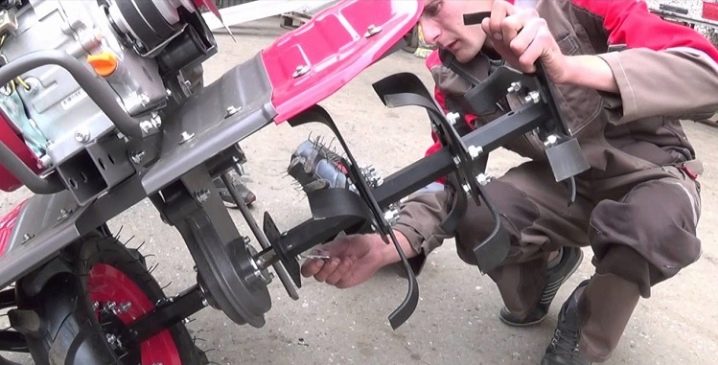

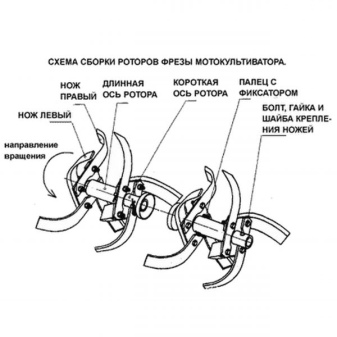

The process of installing a cutter on a walk-behind tractor is quite simple, but before starting work, you should carefully study the manufacturer's instructions and understand the installation features. The standard cutter design includes a rotor axle, a pin equipped with a special lock, several knives and fasteners. The installation of this equipment should be done in such a way that the cutter rotates counterclockwise. Tillers are self-sharpening tools that greatly simplify the process of using them. In other words, it will not be necessary to constantly disassemble the structure in order to sharpen the knives.

It should be noted that problems may arise during the installation of the cutter., therefore, experts do not advise to carry out the installation yourself - it is best to get an assistant in advance. The installation of a saber cutter deserves special attention. The fact is that it is not a monolithic structure, so first you have to properly assemble the product. The main thing is to establish the correct direction of rotation, since without this the device will not perform its tasks.

Collecting such an element with your own hands for a walk-behind tractor is quite easy, because this is a task that is quickly mastered, but first it is better to study the functions that the unit will have to perform. Before starting the homemade assembly of the saber cutter, you need to carefully understand the drawing, and after installation, it is imperative to check the unit for operability. Usually, the first time it is not possible to fine-tune the equipment, so you have to make some adjustments to its operation.

Thus, cutters represent one of the most important elements for ensuring the efficiency of the walk-behind tractor. You can buy them at almost any specialty store. A large selection allows each person to choose the best option depending on the model and other features of their walk-behind tractor. The process of installing cutters is also quite simple and requires only care and an assistant.

With the right approach, the purchased cutters can serve for more than one year without losing their functionality. In addition, you need to carefully study the circuit so that the model can work on a specific walk-behind tractor.

For how to make do-it-yourself cutters for a walk-behind tractor, see the next video.

The comment was sent successfully.