How to choose a starter for a walk-behind tractor?

Motoblocks are not complex designs, but at the same time they contain certain features. For example, when using this device, two starters work simultaneously: main and auxiliary. In addition, spring and electrical options can also act as assistants.

The latter are considered the most popular, since they can be installed on walk-behind tractors without any problems and carry out repair work. A distinctive feature of such starters is also that they are unpretentious, therefore they do not require too careful use.

Features of the manual mechanism

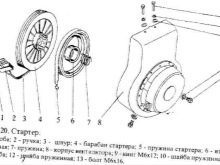

In the selection process, most users usually prefer the manual starter. It has a huge number of advantages over electrical and other options. Such a device includes the following details:

- drum-shaped body;

- several springs;

- various fastening parts and a cord.

It is the manual starter that is most popular, since during operation such devices often fail, so they have to be repaired, but just manual options are extremely easy to repair. Let's consider how the process of restoring the starter's performance looks like.

- Before starting the repair, you need to find a diagram from the manufacturer in order to understand the features of the location of all parts. In addition, it will be useful to understand the instructions.

- You need to prepare a key with which you can unscrew and remove the nuts.

- Before shooting the starter, it is best to take a few photos. This will help restore everything in case you forget the location of certain parts.

- We unscrew the washer, which is located in the center of the drum.

- Find damaged items and replace them.

Thus, repairing a recoil starter does not take too long, which is why this type is very popular. In the process of restoring the starter for a walk-behind tractor, the main thing is to pay attention to any details, even the smallest ones.

Views

For the walk-behind tractor, you can also install other types of starters. Several types can be distinguished among the most popular and demanded on the market.

- Spring loadedwhich are considered the easiest to use and install. In order to start such equipment, you just need to move the handle of the walk-behind tractor. The unit includes a semi-automatic spring, which provides the necessary acceleration of the power plant. In order to replace the manual version with a mechanical one, it will take no more than two hours.

- Electricalwhich are powered by a built-in rechargeable battery. It is the last detail that determines the power level of the device and its battery life. It should be noted that such starters can not be installed on all walk-behind tractors. Only some models are able to work with electricity, so before choosing, you must definitely study the features of your unit.

In the process of choosing any starter, you should understand that in the first year of operation, they are almost all the same. If the company is conscientious, then each device will fully perform the functions assigned to it, but after a year the situation changes. In order for the device to work as best as possible and for longer, you need to constantly take care of it, lubricate and replace failed parts.Only then will the starter boast high performance and durability.

Installation features

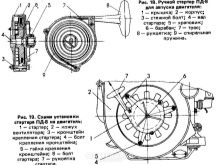

In order for the selected starter to be corrected as long as possible, to be able to fully perform the functions assigned to it, it should be installed correctly. The installation process includes a number of steps.

- First of all, you need to remove the flywheel so that the crown can be installed. Further, the filters are removed from the unit, which opens access to almost all parts of the walk-behind tractor.

- Now you need to get rid of the protective casing. This is quite simple to do: you just need to unscrew the screws that hold the starter basket. In order not to damage any parts during the removal process, it is best to use a special key.

- At this stage, you need to mount the generator in the place allocated for it, wind up the rope, and use it to put the kickstarter.

- The assembled system is mounted on the motor, and the starter terminals are connected to the battery.

As you can see, self-installation of the starter on the walk-behind tractor does not take too much time. The main thing is to strictly follow the rules and tips during the installation. In addition, you should be extremely careful when choosing the starter itself. You must initially make sure that it is suitable for your walk-behind tractor model. For example, not all models can be fitted with an electric starter. When repairing the device, it is imperative to disconnect from the electricity.

If necessary, you can replace the starter in the same way. For perfect device operation, it is best to select the same models that were previously installed on the device. Most power units of motoblocks differ in power of 13 horsepower, so you can use the usual top kit. For replacement, use original components from the manufacturer, which will definitely not harm the integrity and performance of the walk-behind tractor.

Of course, it is much easier to fix something that can be simply replaced. For example, if the cord for the walk-behind tractor has deteriorated, then it can be easily replaced with a new one. But as for the starter spring, here you have to tinker a little. The fact is that it is necessary to carefully study the attachment points in order to choose the optimal spring. If the hook is simply out of order, then it would be much more expedient to make a complete replacement of the mechanism.

Prophylaxis

Selecting and installing a starter is only half the job. If you want the purchased part to work as long as possible, you need to pay close attention to its care. New things always work well. For example, a factory starter only needs one jerk to start the engine. However, after a year of active use, the state of affairs will surely change. In order to prevent the occurrence of such problems, it is necessary to constantly lubricate before starting. In addition, do not overdo it when pulling the handle, as this can cause mechanical damage.

If a kickstarter fails, repairs usually include updating components that have stopped working. For example, the cord is replaced if it is frayed, and the spring from "MB-1" can be refueled only in case of problems with its operation.

Thus, the starter is an irreplaceable part that ensures the operation of the walk-behind tractor. In the selection process, you need to pay attention to the manufacturer, compatibility with the walk-behind tractor itself and the type of model. In addition, you need to pay attention to the constant care of the starter, which will avoid breakdowns and quick failures with active use.

For starter prevention, see the video below.

The comment was sent successfully.