Recommendations for creating a do-it-yourself blade for a walk-behind tractor

In our country, there are such winters that often the owners of individual households are faced with the difficulty of removing a huge amount of snow. Usually this problem was solved by means of ordinary shovels and all kinds of home-made devices. At the moment, when most farms have motor-cultivators available that can be equipped with various types of attachments, snow cleaning, garbage collection and other work has become much easier. In the article we will look at how to create a do-it-yourself blade for a walk-behind tractor.

Design features of the device

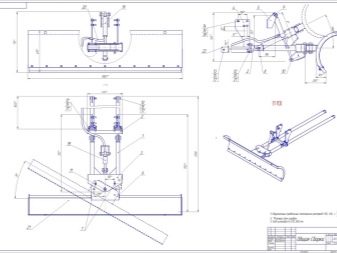

Snow shovels are effortlessly hung on any type of equipment, seriously speeding up and simplifying the procedure for clearing snow. All snow plow equipment for a multifunctional unit includes 3 basic parts: a snow shovel, a plow angle adjustment mechanism and a mounting module that holds the snow plow to the frame of the unit.

There are a number of designs of factory shovels that are part of attachments., however, such a device for a walk-behind tractor can be built with your own hands, especially since there is a wide variety of information and drawings on this problem in the global network.

This makes it possible not only to manufacture equipment with the required characteristics, but also to significantly save money.

The blade is an integral part of the attachments used in conjunction with a motor cultivator. With his support, you can facilitate such everyday work on your own plot of land as collecting garbage in summer, in winter - clearing snow, in addition, leveling the surface layer of the earth and transporting it from one site to another. Snow plows come in different variations, but in their total mass they are endowed with one principle of operation and design. Basically, they have a number of standard working positions.

These are almost always the 3 points below:

- directly;

- to the left (with a turn of 30 °);

- to the right (with a turn of 30 °).

The principle of work with a snow plow for a walk-behind tractor

The mouldboard shovel of the walk-behind tractor must be properly installed before performing its functions. She turns her hands to the right or to the left at an angle of up to 30 °. The positioning process ends with the setting of a suitable angle and the fixing of the shovel in the chosen position with the help of cotter pins. The grip area of a snow plow for a mobile power unit is usually one meter (some modifications may have different values) with a shovel material thickness of 2 to 3 mm. In an industrial environment, these devices are made from high quality steel.

Shovel for a motor cultivator

Mouldboard shovels for motor-cultivators can be equipped with a knife attachment, which is convenient for leveling the soil, as well as rubber attachments designed to eliminate the effects of snowfall. The choice of models of snow plows is extensive; when choosing such a hinged mechanism, you must certainly make sure that the structure can be mounted on an existing motor-cultivator.

Manufacturers do not equip these accessories for motoblocks with a damping device (damping) or prevention of vibrations (spring dampers), because due to the low speed of movement, no special protection is needed against contact with uneven soil relief. When equipping your cultivator with additional snow removal equipment, purchase specialized steel lugs.

Replacing pneumatic wheels with similar devices significantly increases the quality of snow cleaning.

How to create a snow plow from a barrel?

Making a shovel on your own is easy when you have a welding machine, a grinder and an electric drill in your house. Here's one easy way. You do not need to search for the necessary material, since you can use a simple 200-liter iron barrel.

Carefully cut it into 3 slices and you will have 3 curved pieces for the snow plow. Welding 2 of them along the contour line, we get an element with an iron thickness of 3 mm, which is fully enough for the rigidity of the shovel. The lower segment of the shovel is reinforced with a knife. This will require a metal strip 5 mm thick and the same length as the blade grip. Holes are made in the knife with a caliber of 5-6 mm with an interval of 10-12 cm for mounting a protective rubber strip.

The mechanism for attaching the shovel to the cultivator is quite simple and can be done at home. A pipe with a cross-section in the form of a square 40x40 millimeters in size is cooked to a shovel, assembled from two parts of a barrel, approximately in the middle of its height for reinforcement. Then, in the middle of the pipe, a semicircle of thick iron is cooked, in which 3 holes are pre-made, required to stabilize the angles of rotation of the moldboard shovel.

Next, a bracket that looks like the letter "G" is welded from the same tube., one edge of which is placed in a hole in a semicircle, and the other is bolted to the chassis of the unit.

To adjust the level of the blade lift, bolts are used that are screwed into the holes in a piece of tube welded to the hitch and put on the L-shaped bracket.

Making a moldboard shovel from a gas cylinder

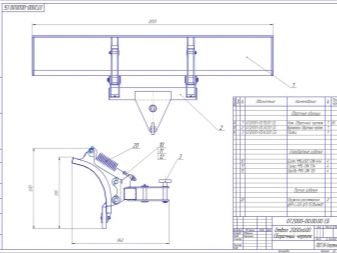

Another available tool for making a moldboard shovel is a gas cylinder. This event will certainly require a detailed diagram. It should indicate the parameters of the spare parts used and the procedure for assembling them into a single structure. Work on the creation takes place in the following order.

- Release excess pressure from the cylinder, if any.

- Cut off both ends of the lid so that the width is one meter.

- Cut the resulting pipe lengthwise into 2 halves.

- Using a welding machine, connect these 2 segments so that the blade height is approximately 700 millimeters.

- The holder for fastening is made as follows. Cut a kerchief out of thick iron. Make a number of holes in it to rotate the blade in different directions. Weld a piece of pipe to the kerchief.

- Weld the prepared product to the snow plow at the level of the holder location on the walk-behind tractor.

- Installation is carried out using a cylindrical rod.

The thickness of the walls of the cylinder is sufficient, there is no need for reinforcement. However, the bottom can be fitted with durable rubber that will remove loose snow and not damage the rolled road. To do this, you need to take hard rubber from the rotary - conveyor lines. The width of the rubber strip is 100x150 mm. Using an electric drill, make holes in the shovel to fix the rubber. To firmly fix the rubber strip, a 900x100x3 mm iron strip is needed. Drill holes in metal and rubber, marking in advance with a shovel. Secure with bolts.

Sheet steel shovel

Some craftsmen prefer to use new material, rather than used elements. So you can assemble a homemade blade made of iron sheet 3 mm thick.To strengthen the device, you can use a steel strip with a thickness of at least 5 millimeters. Metal cutting is carried out according to the schemes. The blade itself contains 4 segments: front, bottom and 2 side. The assembled structure requires reinforcement. For this, components cut from 5 mm thick metal are welded vertically.

Then a rotary device is created. It is a lug with a hole for the axle. The eyelet is fixed by welding to the angle, which is attached to the shovel. The axis is fixed on one edge of the pipe, and with the other edge it is fixed on the walk-behind tractor. The required degree of rotation is fixed with a cylindrical rod (dowel). 3 millimeters is a small thickness, which means it needs to be strengthened. Cut a strip of 850x100x3 mm from a 3 mm thick sheet.

You can fix it with bolts, but you will need to first drill or weld the strip with welding.

To carry out the work you will need:

- sheet metal;

- angle grinder with discs;

- electric drill;

- set of drills;

- bolts with self-locking nuts (with plastic inserts);

- welder with electrodes;

- wrenches;

- profile or round pipe.

If you have the necessary abilities, the job is not difficult. And the created device can be used not only in winter, but also in summer. Improve the site after completion of construction and installation work, plan a site for a children's sandbox, and the like. What type of construction to choose is up to you to decide.

How to make a blade-blade for the "Neva" MB-2 walk-behind tractor, see the video below.

The comment was sent successfully.