Belts for a walk-behind tractor: selection and installation

The high-quality drive belt (accessory belt) for the walk-behind tractor guarantees a long-term use of the device for cultivating the cultivated areas. Based on the intensity of operation and the resource of the equipment, it is necessary to select the appropriate belt of the unit. You cannot purchase the first drive belt for the unit, which is advised in the store. The increased physical properties of the unit will not make it work better if the unit itself is not designed for this.

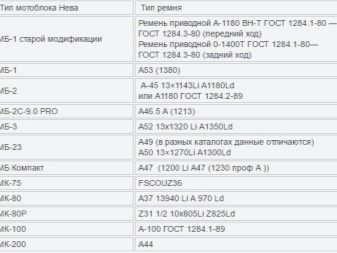

Technical parameters of different modifications

Motoblocks of all manufacturers, whether they are motor vehicles "Neva", "Ural" with the UMZ-5V engine or Hyundai T-500, "Euro-5" and many others are produced almost according to the same scheme. Only in certain episodes do we talk about different power and available functions. The manufacturer "Neva" made an overhead camshaft placement. As a result of the air cooling system, motorcycle belts need to be purchased less frequently.

In the model line "Cascade" the emphasis is placed on the use of a belt drive. The owner of the equipment must, in strict accordance with the technical specifications of the manufacturer, select belts for motor vehicles. The slightest deviation from the prescribed requirements will provoke rapid wear of the mechanical elements. In essence, similar conditions are set for the Zubr units.

We should also mention the Mole unit, which has a belt drive of the same model A-710, A-750, where the length is 710-750 mm, width is 13 mm, and the procedure for replacing them is similar to the “Cascade”.

Motoblocks are endowed with high power, which imposes specific restrictions on the permissible types of belts of the units. It is strongly recommended to focus on products labeled A-1180. In the event of the arrival of an unscheduled or planned repair, a flexible belt drive element with similar parameters is purchased.

Motoblocks made in China are characterized by a very large freedom in choosing a belt.

The belts of units for motor vehicles, as well as for attachments, for example, a belt pump, are selected taking into account only one condition: the length and strength of the product cannot differ by +/- 1.5% from the prototype. In this case, the use of analogs will not provoke repeated failure.

Working at higher speeds

Expensive modifications of motoblocks are endowed with several speeds. The designated function allows you to optimize the procedure for sowing, harvesting or cultivating the field. But on the other hand, the operation of motoblocks is largely directly dependent on the quality of the drive belt. The first thing to remember is that frequent gear changes are not the best way to affect the operation of the unit. For this reason, one should abandon the use of cheap and sometimes low-quality products.

Belting

To choose the right belt for your motorcycle, you should have the following information:

- the type of drive belt that is suitable specifically for your modification of the unit;

- its length;

- tension level;

- type of V-belt transmission (for specific models).

Varieties

Unit belts are:

- wedge;

- toothed;

- forward motion;

- reverse.

To ensure optimal tension and a long service life of not only the entire belt drive, but also the transmission, the size of the unit's belt must be exactly matched to a specific modification of the walk-behind tractor. If you put extremely long products, as well as very short ones, they will wear off rather quickly and will create an extra load on the engine or gearbox. For example, the 750 mm "Mole" belt drive is installed on units with a domestic engine.

In addition to the above, before purchasing it is necessary to check the product from the outside: the belt should not have any damage, scratches, protruding threads, breaks. A quality product is one that retains a distinct factory pattern and cannot be stretched by hand.

How to choose the correct size?

The size of the belt of your unit can be found in the documentation or by the number on the old product (if any). If you cannot find the dimensions, you can use a tape measure and a regular rope (cord). And you can also use special tables.

Replacement and customization

The flexible element of the belt drive on the walk-behind tractor can be independently replaced and adjusted.

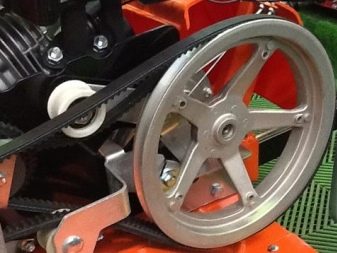

The V-belt transmission reliably communicates the force from the motor, but over time the belt wears out, cracks and gusts form on it.

The task of changing it appears. This can be done at dedicated service centers. This is the most correct choice, but it will cost a lot. You can make a replacement yourself, and if you have repaired your car at least once, you have experience working with equipment.

1. Remove the used flexible element

First of all, remove the plastic protective cover by unscrewing the fixing nuts. After that, the belt of the units is removed by relaxing the tension between the pulley (friction wheel) of the gearbox and the motor.

On some modifications, there are specialized devices for tensioning and loosening belts. But usually this mechanism is absent in walk-behind tractors. To loosen the drive belt tension, loosen the motor fixing nuts (4 pieces) and move it to the right. Then we remove the belt. Do not forget to move the motor to the right (left) side to tighten (loosen) the product only within 20 millimeters.

2. Putting on new products

The installation of a new unit belt is carried out in the reverse order. Then you need to pull it, taking into account its obligatory sagging by 10-12 millimeters. Be sure to check the alignment of the gearbox and motor friction wheels. We wrap the nuts of the motor fasteners diagonally.

When not in operation, the belt should rotate without difficulty on the input shaft, but not jump off it. To bring the belt of the aggregates to the working status, the clutch handle is squeezed out, the cable lifts the pressure shaft upward, pulling the belt.

3. Self-tensioning

When the new product and the loop former (damper) are mounted, they need to be tensioned and adjusted, since the belt will immediately bend, which is considered unacceptable. This can shorten the duration of its use, the wheels will start to slip, the engine will start to smoke at idle.

To perform tension, it is required to clean the friction wheel with a rag, and also to loosen the bolts fixing the motor to the chassis, with a key of 18 turn the adjusting bolt in the direction of movement of the clock hand, tightening the device. At the same time, it is necessary to try the tension of the drive belt with the second hand so that it springs freely. If you overtighten it, it will also have a detrimental effect on the reliability of the bearing and belt.

During installation, all measures must be carried out gradually and carefully in order to exclude damage to the product. This can provoke it to rupture or premature failure of the drive.

Upon completion of mounting and tension, check for distortions. The new product must be level and free from kinks and distortions.

Processes that exhibit insertion and tension errors:

- vibration of the body during movement;

- overheating of the drive belt at idle speed, smoke;

- wheel slip during operation.

Running in

After installing a new product, it is required to run the walk-behind tractor without exerting a load on it, so as not to damage the structural elements. When using the unit, it is necessary to tighten the gear mechanisms after every 25 hours of operation. This will prevent the rapid wear of the friction wheels, will ensure the smooth movement of the walk-behind tractor.

For information on how to change the belt on the walk-behind tractor, see the next video.

The comment was sent successfully.