Rules for plowing the land with a walk-behind tractor

Plowing the land is one of the compulsory agrotechnical measures and is carried out in early spring and late autumn. Thanks to this procedure, the soil is saturated with oxygen, most of the weeds are removed and the duration of the snow cover is significantly increased. And if you can completely do with an ordinary shovel to dig up several beds, then for processing even a small country garden or a potato field, you cannot do without the use of mechanized equipment... And in this case, a walk-behind tractor comes to the rescue - a universal multifunctional unit, which is an indispensable assistant for summer residents and farmland owners.

How to choose a walk-behind tractor?

Motoblocks are versatile devices and are capable of performing a dozen different operations. With their help, you can not only plow the land, but also plant vegetables, weed plants, huddle potatoes, harvest and mow grass. In addition to agricultural applications, walk-behind tractors are widely used for collecting snow and garbage, transporting various goods weighing up to half a ton, as well as a snowmobile and a mini tractor. In addition, some high-tech models are equipped with a special shaft, on which additional attachments are installed, allowing you to cut firewood, pump water and even provide owners with electricity.

Thus, when choosing a walk-behind tractor, it is necessary to consider what other functions besides plowing the site will be assigned to the unit.

The second criterion after functionality is the engine power. On this basis, the aggregates are divided into light, medium and heavy. Light and medium models are intended for everyday use and weigh from 50 to 100 kg. They are equipped with engines of 4-8 liters. with. and have, as a rule, 2 forward and one reverse gears. Low-power units with a width of 70-80 cm are quite suitable for processing plots of no more than 15 acres. Motoblocks equipped with an average power engine of 7-8 liters. with. and 90 cm wide, designed for larger-scale works and are capable of serving areas from 15 to 40 acres.

The heavy class is represented by models with a powerful engine of 9 or more horsepower, they are used on fields up to 1-1.5 hectares. The capture width of such units is 100 cm, and the weight exceeds 100 kg. Such models are often equipped with a diesel engine and are distinguished by good tractive effort, high service life and low diesel consumption. However, at an air temperature of 2 degrees and below, diesel engines start slightly worse than gasoline ones and take longer to warm up. Therefore, if you need not only to dig up a garden, but also to remove snow, then it is better to purchase a gasoline model.

In the case of using a walk-behind tractor as a self-propelled device or a tractor for transporting goods, you should choose models with a wheel diameter of at least 45 cm. For these purposes, it is also better to choose a deep tread. If the walk-behind tractor will be used only for plowing, then additional purchase of lugs and a plow will be required. Despite the fact that most of the units have a pair of cutters as standard, their strength is often not enough for heavy soils and virgin lands.Therefore, you need to take care of purchasing additional attachments in advance.

How to prepare for work?

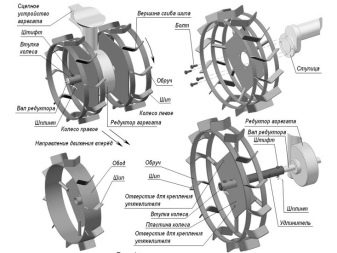

Preparing the machine for work includes the installation of lugs, as well as attachment and adjustment of the plow.

- Installation of lugs. These devices are metal wheels with a diameter of up to 60 cm and a width of 17-20 cm. There are also thinner samples on sale, but it is not recommended to buy them. This is due to the fact that it is very difficult to make an even furrow with thin hooks: the walk-behind tractor will chat in different directions and it is rather problematic to cope with it in such conditions. In order to install the lugs, the unit is placed on a flat area, the native wheels with rubber tires are unscrewed and the hubs removed.

Hook hubs are put on the drive axis, fixed with pins and pinned.

The hubs of the hooks are somewhat longer than usual, so their use leads to an increase in the track width, which makes the walk-behind tractor more stable. After the hubs are securely attached to them, the lugs are mounted. When attaching metal wheels, make sure that the tread tapers forward. It is advisable to choose the hooks in such a way that, after hanging them, the total weight of the unit is more than 70 kg. Otherwise, the machine will slip and the processing will turn out to be uneven and of poor quality. If you purchase too light lugs, you need to take care of additional weighting of the structure. To do this, you can purchase a set of additional weights, the installation of which will provide the required weight.

- Installation and regulation of the plow. The plow is secured by means of couplings, which are attached to the unit with a king pin. It is recommended to connect the hitch and the unit with a 5-6 degree backlash. If you fix the plow motionless, then when plowing, it will begin to wind the walk-behind tractor from side to side, which is due to the uneven effect of the soil on it. It is not recommended to fully tighten the nuts when connecting the hitch to the plow. This is due to the fact that the process of adjustment lies ahead, during which they will have to be tightened and then loosened more than once.

To carry out the adjustment, it is necessary to install the unit on bricks or boards stacked on top of each other. The height of such a structure should be equal to the plowing depth and be 20-25 cm. In this case, the lugs should be fixed, thereby providing the walk-behind tractor with complete immobility. Then the plow is positioned so that the field board lies on the ground with its entire length. In this case, the plow stand should be located strictly perpendicular to the ground and parallel to the inner end of the hook.

Then the slope angle of the field board is adjusted, while the distance from the plow nose (share) to the heel should correspond to 3 cm.If the slope adjustment is neglected, then the plow will start burrowing into the ground during operation, the engine will overheat and the work will have to be stopped. Next, you need to adjust the track width. To do this, the right edge of the share is set in line with the inside of the right lug.

With this arrangement, the soil will be cut absolutely evenly, and it will become easier to control the unit.

- Unit start-up. Before starting a gasoline or diesel engine, check the oil level and fill the tank with fuel. Two-stroke gasoline models run on a mixture of gasoline and engine oil, while powerful four-stroke “use” pure A-92 and A-95 gasoline. When refueling a walk-behind tractor with diesel fuel, you should take into account the temperature regime and in the cold season, fill in winter diesel fuel. Also, before starting, you should check the performance of the steering wheel, gas, reverse and clutch, after which you can start.

To turn on the gasoline engine equipped with a manual starter, open the tap on the fuel tank and set the choke lever to the "Start" mode. Then, without turning on the ignition, 3 to 5 movements of the starter are performed, after which the ignition is turned on and the engine is started. As soon as the engine has started, the suction is immediately transferred to the "Work" mode. On walk-behind tractors equipped with an electric starter, starting the engine is even easier. To do this, simply turn on the ignition, while the electric pump pumps fuel into the carburetor and the engine starts.

Before starting the diesel engine, all the air in the system is expelled with an electric starter, and after diesel fuel takes its place, the engine is started. If the engine is equipped with a manual starter, then simply open the diesel fuel supply valve, set the gas and press the decompressor. Then, a few strokes are made with the starter, the decompressor falls into place and the engine starts.

How to plow?

In order to properly plow the area, it must be well prepared. To do this, a cord is pulled along its border for a reference point, which is especially recommended for people who will plow the garden for the first time. This is due to the fact that during operation the plow leads a little to the right, which is why, without the appropriate skill, it will be difficult to make an even row.

When plowing the second and all subsequent rows, the implement wheel will follow the already formed furrow.and the cord is no longer needed. Then you should manually collect large stones, uproot the stumps and remove the driftwood. After the site is prepared and the engine is running, the speed is turned on and plowing is started.

The second is considered the optimal speed for the operation of the walk-behind tractor, however, when changing the plowing depth or when switching to a different type of soil, the first can also be used.

It is recommended to drive the first furrow in a low gear, which is due to the need to form the initial row evenly and accurately. Indeed, in the future, it will be he who will serve as a guide for all subsequent furrows. After passing the first row, the plowing depth is checked: it should be within 20 cm.Then the walk-behind tractor is deployed, the right lug is installed in the furrow, the 1st speed is turned on and they go in the opposite direction, making sure that the metal wheel does not go beyond the furrow. If everything is done correctly, then the earthen ridge will be located at a distance of 10 cm from the previous one.

If you need to plow a small area, you can do without a plow. The basic set of motoblocks includes saber cutters, with the help of which the processing of any land of complexity and composition, including virgin and stony soils, is carried out. In addition to plowing, cutters are used to mix the soil when applying fertilizers, to remove weeds and loosen the soil.

If it is required to improve the quality of plowing, then work is carried out using a transport-arable module. For this, the plow is not attached to the walk-behind tractor itself, but to the adapter frame. Due to the presence of an intermediate link between the plow and the unit, the impact on the walk-behind tractor is significantly reduced, and plowing is easier and safer. In addition, the speed of the walk-behind tractor noticeably increases. And if with traditional plowing it is 5 km / h, then in the case of using the adapter it increases to 10 km / h. However, in comparison with the traditional method of fastening the plow, when using this method, the overall maneuverability of the unit is lost, which, however, is noticeable only in small and tight areas, with an abundance of cultivated plants growing along the edges. If the work is carried out on a large potato field, then the use of the adapter is very convenient.

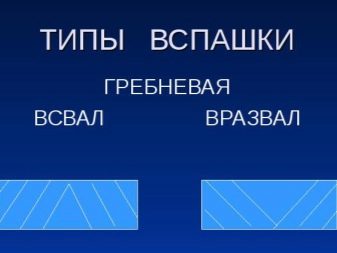

Plowing methods

Plowing a vegetable garden can be done in several ways.

- Vsval. When using this method, work starts from the center of the site.Having reached its edge, the unit is deployed, the right lug is placed in the furrow and moves back to the center. At the same time, the ridge of the earth turns out to be quite large. The advantage of this digging technique is the fact that if there is snow on the site, it does not melt for a long time, falling into the furrows and saturates the soil with moisture.

There are no particular drawbacks to the method, which makes it the most common and popular among the majority of farmers.

- Took it. In this case, the movement starts from the right side of the site. Having reached the end of the row, the walk-behind tractor is driven to the left edge of the site and moves in the opposite direction. In this way, the entire plot is plowed until the rows meet. Using this method allows the plow to turn the soil and fill it with previously applied fertilizers.

- Towards the winter. The garden is plowed with a walk-behind tractor twice a year: in spring, just before planting crops, and in autumn after the last harvest. Autumn processing is considered especially important. It completely kills weeds and effectively loosens the soil. This promotes normal air exchange, ensures proper drainage and prevents mold and pathogens from appearing. The timing of autumn plowing depends on the weather conditions in the region, but it is always done before the first frost.

Advantages and disadvantages of mechanical plowing

The use of a walk-behind tractor when plowing and leveling the site has a number of indisputable advantages over manual processing.

- Using the unit allows you to perform work with a special quality, in a short time and with a minimum of labor costs.

- Due to the multifunctionality of the walk-behind tractors, it is possible to carry out several more agricultural procedures, such as loosening the soil, removing weeds and applying fertilizers.

- With mechanized plowing, the depth of the furrows is much greater than with manual digging with a shovel. In addition, the soil is cultivated more evenly, due to which its general condition is noticeably improved. This is due to the normalization of air exchange, free access of oxygen and more efficient soil moistening during the passage of precipitation.

- According to the observations of experienced farmers, the yield in the fields plowed with a walk-behind tractor doubles.

However, along with the obvious advantages, there are still disadvantages to mechanized plowing. These include the impossibility of using the technique on deep-rooted whole woods. In such cases, only manual removal of long rhizomes is required.

In addition, with the annual use of the deep plowing method, there is a loss of the natural fertility of the topsoil, which is why the land needs fertilization or periodic rest.

Recommendations

In order for the work with the walk-behind tractor to be easy, and to work the soil efficiently, you must follow a number of simple recommendations.

- Plots of up to 6 acres are best cultivated with cultivators. But if it is decided to use a walk-behind tractor, then instead of a plow, saber or claw cutters should be installed.

- It is recommended to use a mounted plow when plowing fields with an area of more than 1 hectare. However, the edges of areas and areas with complex geometries are also best handled with milling cutters.

- In the process of work, it is necessary to carefully monitor the state of equipment and prevent oil from leaking from the transmission. Otherwise, harmful liquid will get into the treated soil and cause its partial contamination.

- When plowing virgin lands, as well as when processing stony and clay soils, it is necessary to use weighting agents. Otherwise, there is a great risk that the walk-behind tractor will start jumping on virgin soil and deep plowing will require great effort.

- When using cutters, it is recommended to equip their ends with protective discs.This will reduce the likelihood of cultivating adjacent lands and will allow plowing strictly along the boundaries of the site.

- To reduce the load on hearing, you must use special headphones or earplugs, and to partially neutralize the vibration, you should wear gloves. In addition, when plowing, it is necessary to move from the leeward side, which will minimize the harmful effects of exhaust gases. If you have to plow in a large greenhouse, then you should ensure good ventilation of the room. To do this, open all windows and doors, and periodically turn off the engine and ventilate the greenhouse.

- Refueling the fuel tank, as well as changing the engine oil, must only be carried out with the engine stopped. In this case, it is advisable to pass the fuel through a funnel with a special filter.

- It is strictly forbidden to operate the walk-behind tractor near an open fire and wipe it with a cloth soaked in gasoline.

The comment was sent successfully.