How to make attachments for a walk-behind tractor with your own hands?

In order to increase the capabilities of the walk-behind tractor, it is enough to equip it with various attachments. For all models, manufacturers have developed numerous add-ons, the use of which makes it easier to work on the ground.

On sale you can find plows and seeders, hillers, furrow diggers, sledges. The choice, of course, is large, but the cost of such equipment is too expensive for many. But it is quite possible to make it on your own from cheaper or used materials.

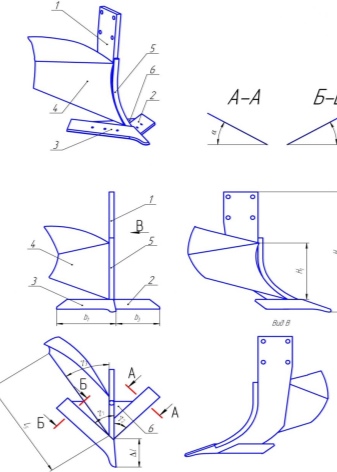

How to make a flat cutter with your own hands?

A practical addition to the walk-behind tractor is a flat cutter. This is an indispensable assistant who creates beds, weeds and spuds plantings, levels, falls asleep, loosens the ground. The possibilities of such a nozzle are almost endless.

If you place the blades of the plane cutter on the left and lead in the same plane with the soil, then you can weed or loosen the ground. Raising the appliance slightly, the blades turned to the left will mow tall weeds. If the blades look down, then it is easy to create beds with them.

The flat cutter will again help to form grooves for planting and fill in the seeds. This is the function of the burier.

You can use the Fokin flat cutter as a hitch for a walk-behind tractor. He has the necessary holes for hanging on the structure. If a flat cutter of a different size is required, then you can make it yourself. Drawings and a small metal workpiece will help with this.

The metal must be of sufficient thickness and strengthso that in the future it can act as a blade. The sheet is heated with a blowtorch and bent according to the pattern. When the plane cutter is in shape, it is cooled with water. In order for this workpiece to become an attachment, it is necessary to make holes for fasteners and sharpen the workpiece with a grinder.

A sheet of metal can be replaced with a piece of pipe, to which pieces of metal are attached like blades. They need to be sharpened.

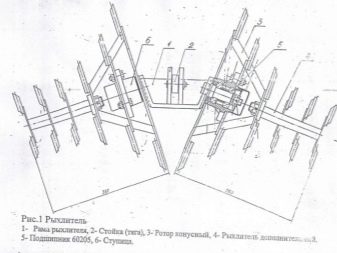

Dimensions and features of the manufacture of hedgehogs

A tiller with an attachment for growing potatoes will save time and effort when caring for this crop. Weeding hedgehogs are a functional attachment that allows you to quickly and efficiently defeat weeds. In the process of weeding, the plants are not simply cut, but uprooted. The land around the plant is well loosened and huddled. Thanks to this, the plant not only gets rid of weeds, but also receives a sufficient amount of water and oxygen.

Hedgehogs can be purchased at almost any agricultural store, but at a fairly high price.

Based on the diagrams and drawings, you can make them yourself.

Components for hedgehogs:

- 3 discs made of metal or a ring;

- a small piece of pipe with a diameter of 30 mm;

- steel rods for cutting thorns.

Preferably use rings instead of discswhich will lighten the whole structure. The sizes of rings for making hedgehogs of a walk-behind tractor are different. The most common are 240x170x100 mm or 300x200x100 mm. The rings are attached to the pipe through jumpers. The connection should be made at an angle of 45 degrees with a distance between the elements no more than 15-18 cm.

The spikes, cut from a steel rod 10-15 cm long, are welded onto the rings and the axle itself.Depending on the size, they are attached to a large ring in the amount of 15 pieces, to a small one - 5. Also, several pieces can be welded onto the axle.

To facilitate work with the design, a walk-behind tractor with hedgehogs is equipped with additional wheels.

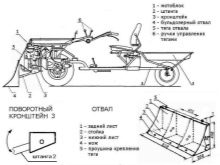

We make a snowblower bucket with our own hands

The walk-behind tractor will come in handy on the farm not only in summer, but also in winter. It is often equipped like a snow blower. It is enough to make a bucket for a walk-behind tractor, and an iron assistant will do the hard work.

A snow shovel is usually made from a 200 liter iron barrel. You will also need metal strips, a square pipe, rubber and steel plates and fasteners - bolts, nuts. From tools - pliers or pliers, drills and drills for metal, wrenches, grinder, welding machine.

The side parts are cut out with a grinder at the barrel. Then the workpiece is cut into three pieces. Two of them are welded along the contour. The remaining third of the barrel needs to be divided into metal strips, which will be the bucket knives. Three 6mm diameter holes are drilled into them for attachment to the edge of the bucket. Instead of a barrel, you can use a metal sheet, which will need to be bent by heating.

A strip of metal is welded to the bottom of the bucket to make it heavier. The metal strip is completely covered with rubber to prevent wear. Then the bucket is attached to the walk-behind tractor. To protect against corrosion, a homemade bucket is primed and painted.

You can turn a walk-behind tractor on wheels into a snowmobile using a trailer and winter wheels... With the help of the channel, the trailer is fixed to the frame. Used truck cameras are used instead of expensive wheels. On each wheel, the deflated chamber is secured with chains and inflated again. Equipping a snowmobile machine is quite simple and homemade sleds.

How to design a trencher?

A homemade trencher is a hinged attachment to a walk-behind tractor that allows you to quickly and effortlessly dig trenches and holes. It is a kind of compact excavator that is both maneuverable and economical. Moves on a wheeled or tracked chassis.

Digger attachment allows you to dig trenches and holes even in frozen ground... The walls of the trenches are flat, without shedding. The excavated soil is light and crumbly and can be used for backfilling.

Two cutters are fixed on the front suspension, on the rear - a shovel for extracting soil from the trench. It is imperative to attach safety guards to the cutting discs and the chain drive. By the same principle, a drill bit is made from a metal rod and plates.

Manufacturing of other suspended structures

The walk-behind tractor can be equipped with a variety of useful devices - a plow, a rake, all kinds of shovels, mowers, skis, brushes. Desire, clear diagrams and description of work will help to repeat store counterparts of hinged elements and even improve them, since they will correspond to individual requirements and conditions.

So, to cultivate the land, a plow is needed that can overcome virgin soil overgrown with grass, wet or stale soil. To make it, you need a steel plate with a thickness of about 5 mm. Using the rollers, the plate is bent into a cylinder. The edges are sharpened with a grinder.

The resulting home-made plow is hung on the stand of the walk-behind tractor through the hitch.

By the same principle, it is easy to make a furrow-forming attachment. It is good if there are racks from the cultivator. They can be attached to a corner or make two racks from scrap materials... For this, plates are cut from a metal sheet with a thickness of 1.5-2 mm. The size of the plates should correspond to the depth and width of the furrow. They are fastened with bolts to the struts of the structure. You can use such a nozzle for instillation... One has only to give the plates the required shape. They should be in the form of a disc or circle, located at a certain angle.From above, such plates are located closer than below. Due to this, the discs, while rotating, open the cavities outward.

The attachment to the cranberry walk-behind tractor contains a self-propelled crawler platform. The intake is fixed on the swing frame of the platform. It is made in the form of a box with bent parallel teeth. Moving, the device with the help of the fan pulls the berries into the box. The fan is powered by the engine... Screw-shaped spirals are installed in the box.

Plucked cranberries are heavier than garbage, so they fall to the bottom of the container. Leaves, small specks that fall along with the cranberries, are removed through the hole along with the air flow from the fan.

A brush for a walk-behind tractor is used to clean the area not only from leaves, but also from shallow snow. Simplicity, efficiency and versatility of use are the obvious advantages of this hinged element. A brush shaft is vertically attached to the walk-behind tractor. A ring and discs with brushes are alternately put on it. The diameter of the rings is 350 mm. The width of the grip of such a brush is usually made no more than one meter. So the walk-behind tractor remains maneuverable and covers a fairly large surface area for cleaning.

The length of the bristles is 40-50 cm, otherwise it will soon begin to wrinkle and wrinkle. It will not be possible to restore the properties of the bristles, just attach new discs. The speed of the walk-behind tractor with a hinged brush fluctuates in the range of 2-5 km / h, depending on the engine power of the unit.

How to make a plow for a walk-behind tractor with your own hands, see the next video.

The comment was sent successfully.