Attachments for motoblocks: varieties and subtleties of choice

The walk-behind tractor itself is an engine, traction force. It becomes useful in the household thanks to attachments. This technique can work all year round: in the spring to plow the land and plant seeds, potatoes, and in the summer to huddle, water the plants. The machine is capable of harvesting in autumn and removing snow in winter. The walk-behind tractor is also used for preparing firewood, when mowing grass, as a small truck for transporting heavy loads. Every year new models of equipment for the universal worker appear.

What it is?

A walk-behind tractor is similar to a mini-tractor; its real involvement in the work begins with equipping with attachments. The "symbiosis" of the engine and all kinds of attachments allows you to plow, loosen, chop wood, transport cargo, mow grass, and clean snow. All these devices can be put on a walk-behind tractor and get a miniature excavator, tractor or lawn mower.

A walk-behind tractor is often confused with a cultivator, and both carry out pre-planting work on the ground.

But it should be understood that the capabilities of the first are much wider than the second, although they completely depend on the attachments. A walk-behind tractor is more powerful than a cultivator, its tractive effort comes from the wheels. It also has an engine, often an internal combustion engine, a transmission that regulates speed and a gearbox, and a steering wheel (remote control). As you can see, the device is simple and self-repairable.

Attachments of various types are purchased for the walk-behind tractor, for example, a stationary one is mounted to an adapter. The activator depends on the rotational power of the gearbox. On the axial equipment, the nozzles rotate under the weight of the walk-behind tractor. Landing gear attachments refer to adapter attachments.

Typical components

The industry produces simple and complex equipment for motoblocks. Typical accessories include the simplest attachments that are included with the unit at the point of sale. Or they can be purchased at the time of purchasing the equipment for an additional fee. Let's take a look at some of them.

- Grousers are a mandatory addition to the walk-behind tractor. These are special iron wheels with studded elements that give stability to the equipment during field work. With the help of lugs, the walk-behind tractor can easily move on any, even difficult soils. In addition, they contribute to better soil cultivation.

- An all-season attachment for a walk-behind tractor will ensure its operation on a caterpillar track. Thanks to its increased traction, it improves flotation on difficult terrain and snow cover.

- Typical accessories include a lifting linkage. It is in any position of the lifting of the load is horizontal to the surface. The force on the hitch pedal does not exceed 10 kg per 100 kg of load.

- Flat-cut rippers are mounted on a walk-behind tractor for grinding weeds in the ground. The cut weeds eventually turn into humus (organic fertilizer).

- The mulcher for a walk-behind tractor copes well with tops, weeds, weak undergrowth, but it cannot process tough trunks of corn or sunflower.

- A weeder or weeding cultivator can be purchased at agricultural equipment stores, they come in different shapes and sizes. This is one of the most popular field work sheds.

- The baler for the walk-behind tractor (baler) forms bale briquettes with hay.

- A three-point hitch is installed on the walk-behind tractor, but it is important to know the type of construction (plow, harrow, etc.).

- Hedgehogs are discs with spikes of different sizes; they are used for hilling and weeding potatoes.

- Motoblocks equipped with brushes are used to clean sidewalks, roads from falling leaves and snow drifts.

These implements are useful throughout the year.

Sophisticated attachments

Composite attachments are a type of motoblock stationary equipment. They are purchased for the processing of land, seasonal care for plant crops, harvesting and other economic needs. Thanks to them, sowing takes place in the shortest possible time, when the count is in a matter of days. Motoblocks are equipped not only with seed drills, but also with potato planters. In addition, a large number of equipment is designed for other uses. Having familiarized ourselves with the simple nozzles, we will try to deal with those that are classified as complex.

Plow

The plow is perhaps the most popular attachment for a walk-behind tractor. It can be fully appreciated by those who had to dig up a land plot manually for long days. The equipment, equipped with a plow, will plow the field quickly, completely taking physical labor upon itself. The plow is capable of plowing the ground to a depth of 15-25 cm. At the same time, it looks quite simple, in the form of a steel plate on a metal arm, with a skimmer element. The simplicity of the design allows many craftsmen to make it on their own. This mechanism is ambiguous, it has its own varieties.

- The plow is standard. Endowed with a wide ploughshare (knife) and a curved blade, which gives it the ability to cut weeds and turn over layers of soil.

- Reversible plow. A more complex design, which consists of two plows, fixed at a certain angle on the frame, with dumps, "looking" in opposite directions. While one is plowing the soil, the second is in a state of reserve, the plow is changed on the next furrow, this greatly simplifies the work of the plowman.

- Zykov's plow. This device turns and crumbles the soil layer more efficiently due to the improved shape of the moldboard.

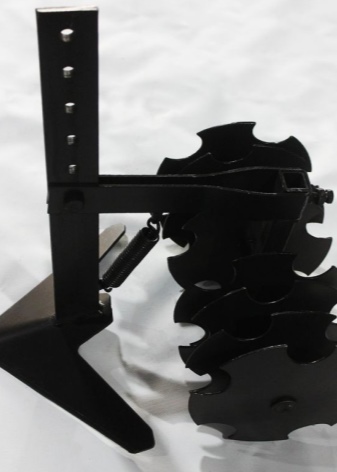

Harrow

With this construction, the plowed surface is leveled. The equipment looks like a steel lattice with sharp spikes, thanks to which the harrow is called a tooth harrow. There is one more type of harrow - disc harrow. It differs from the tooth by the presence of rotating knives made in the form of disks.

This model is a better quality ripper, it copes better with crumbling and leveling the soil.

Hillers

The name of the equipment speaks for itself, it is a design that helps to huddle plants. In addition to adding soil under the seedlings, the hiller forms furrows and even covers them with the seeds. There are different types of hillers.

- Lister - the simplest model with two fixed wings and a constant soil grasping width, creates a row spacing of 20-30 cm. It is clear that such a device does not regulate the working width, so you will have to be content with the row spacing that the hiller is capable of. Lister equipment is hung on lightweight types of equipment.

- Variable width furrower has movable fenders and is adjustable, so the row spacing can be changed at your discretion. Such a nozzle is used on equipment that has a power of at least four horsepower. Unfortunately, this is an energy-intensive work, since part of the soil from the formed bumps is poured back into the holes.

- The disc hiller is more thought out. It is easy, efficient to work with it and the developed ridges turn out to be much higher. When buying a hiller, it is worth choosing thick, large-sized disks made of alloy steel. Such a purchase will cost more than similar models, but after it it is difficult to switch to other equipment.

- By quality dutch-type hiller inferior to the disk one, but surpasses the usual one in that its wings are able to move up and to the sides when cornering. The design allows you not to do unnecessary work and reduces the energy consumption of hilling.

- Propeller (active) the quality is not inferior to disk. Its principle of operation is different: with the help of blades, it crushes the soil together with weeds and makes loosened mounds.

Cutters

The most common type of equipment designed for field work. The cutters plow easily, loosen the soil, ridding it of weeds. With their help, you can apply fertilizers and special fertilizing. This equipment is varied in shape, number and location of knives. It looks like an axis with lamellar knives fixed on it at different angles, which, as they rotate, enter the ground in turn. If blocks with cutters are placed on the sides of the walk-behind tractor, they will replace the wheels.

There are two types of cutters: saber (active) and crow's feet.

- Active knife made of alloy steel, it has the form of ends bent in different directions, they are used for work on soft soil.

- Crow's feet made of mild steel. They are effective due to their shape, which truly resembles the legs of geese. Narrow elongated metal plates with triangles at the ends, fixed on one rod and turned in different directions.

Such equipment is used for hard soils, it does not need sharpening for a long time.

Equipment for working with potatoes

- Potato planter. Those who planted potatoes by hand probably dreamed of automating their work. With the help of a walk-behind tractor and special equipment (potato planter), such an opportunity arose. The equipment is equipped with a plow that creates a furrow for planting potato tubers. A special container with potatoes is fixed on the frame, from which, after an equal period of time, the tubers fall into the furrow. The frame is equipped with hillers, which immediately fill the planted potatoes.

- Potato digger. Digging up potatoes by hand is also not an easy task. A technician equipped with equipment for collecting tubers (potato diggers) comes to the rescue. They look different (fan, vibration, conveyor), but the principle of action is the same for all: sharp pins stick into the ground and pull the bush out together with the roots, after which it remains only to collect them. There is equipment along with bunkers where potatoes extracted from the soil are poured. This kind of harvesting is even more convenient.

Bed former-film layer

With the help of such equipment, a film is laid out with sowing of seeds. The technique forms a ridge on the soil already prepared by cutters. At the same time, the film is laid, its edges are sealed and the film material is punched for sowing and plant growth. This planting method will further help retain moisture in the soil and negatively affect the growth of the weed, which will not easily get along under the film. Most often, the bed former is used for planting strawberries and strawberries.

Trencher

Attachments of this type turn the walk-behind tractor into a miniature excavator. It is quite maneuverable and can be used in non-standard situations, in areas between buildings and trees. Trenchers are made on the basis of wheels or tracks, they are equipped with various types of equipment (knives, moldboards, cutters) and are capable of producing trenches up to two meters deep. They are used for different purposes: digging ditches, when building a foundation, planting trees, for arranging a drainage system.

Trenchers are able to traverse frozen ground as well as unstable soils, leaving behind neat compacted ditch walls.

Grain thresher

The equipment consists of a container for grain, a drum chamber, a conveyor and a device for separating and threshing grains. From the container, the crop enters the straw walker, where the grain is separated from the straw. Further, the grain is cleaned and blown by the efforts of the fan. If the nozzle does not have a fan, the grain will have to be processed manually (sowed). With the help of this equipment, the grain is knocked out of the ears and separated from them. The device of high quality gives the safety of grains up to one hundred percent. For the efficient operation of the equipment, the moisture content of the raw material is about 20%.

Caterpillar "Krutets"

It is universal and suitable for installation on domestic and imported walk-behind tractors of any power and weight. With a sturdy frame, the Krutets is able to withstand any weather conditions, so it is suitable for all seasons. Such equipment can be used to transport goods, go hunting and fishing.

Rotary mower

This type of attachment allows you to mow vegetation of different levels of height and thickness, while freeing the farmer from heavy routine work. Due to the design features of the mower, it is often called disc, and according to the method of connection with the walk-behind tractor, it is divided into trailed and mounted. The cutting knives on the mower can be located in front, behind or on the side in relation to the walk-behind tractor, in any case they are fixed on a frame with a support wheel, as soon as it starts to move, the discs begin to mow vegetation. In addition to the rotary, there is a segment mower. It seems complicated, like a hair clipper. Her work is more skilled and used for large areas.

Snow removal equipment

A snow blower is a bucket that grabs snow and throws it to the side of the road at a distance of 3 to 6 meters, depending on engine power. To work with wet snow, a nozzle is used - a blade-shovel, which shovels snow with water and ice up to 30 centimeters thick. The more powerful the motor and the larger the equipment, the more precipitation and the wider the territory the equipment can remove. Despite the good bottom line, snow management is labor intensive and energy intensive.

And snow blowers are more expensive than many other types of attachments.

Sweeping equipment

To care for areas with expensive decorative coatings, there are brush attachments. With their help, garden paths, lawns, curbs are cleaned.

How to choose?

The choice of attachments to some extent depends on the power of the motor-block motor. This technique is of three classes: light (household), medium (semi-professional) and heavy (professional). Shaft with power take-off promisingly increases the capabilities of technology, with its help attachments are equipped.

Hinged nozzles for various types of economic activities often cost more than the walk-behind tractor itself. To make a choice, you should think about which jobs are the most time consuming. For them, you can choose more complex equipment. Simplified nozzles are quite affordable to make yourself.

Sometimes for soil cultivation, they do not know which is better to choose - milling cutters or a plow. To choose, you should study the features of the soil of your site. To plow a field with soft soil, milling cutters are used, and a plow is used to work on hard soil.

Choosing a small walk-behind tractor for a summer residence, many turn to the Czech-made model "MF-70". It can be used for mowing grass in the area, removing snow, delivering small loads. Due to its compactness and maneuverability, "MF-70" is used for work in hard-to-reach places. To help gardeners and truck farmers, a new model of the StavMash BM-15 walk-behind tractor has been developed. This technique has already proven itself well, with the help of attachments, any work on the garden plot is performed.

The Brado BD-1600 walk-behind tractor is purchased for work on small farms. It is equipped with the most powerful four-stroke gasoline engine. The equipment weighs 120 kg, is capable of plowing depth up to 30 cm. Self-propelled walk-behind tractor SW 360 (SunGarden MF 360 S) is designed for professional use. There is a large selection of equipment for the technique, the replacement of which takes place without the use of tools.

A walk-behind tractor with attachments will facilitate the work of a summer resident with a small land plot and a farmer with a medium-sized field. The amount of work performed directly depends on the engine power and the specifics of the attachments.

Next, see the video review of attachments for the walk-behind tractor.

Very interesting! I plan to make a flat cutter and in this video I saw what I was looking for! Thanks to!

The comment was sent successfully.