Selection and installation of wheels for a walk-behind tractor

Many owners, purchasing a walk-behind tractor for a household, pay attention only to its performance indicators and motor power. But wheels are also considered an important criterion in choosing this technique, since they are the chassis and allow the power unit to move around the personal plot. Wheels for a walk-behind tractor are supplied by the manufacturer in a complete set, but during long-term operation and loads, they may fail and require replacement.

Peculiarities

Wheels, just like mechanical units, are available in several types. Today the market is represented by a huge assortment of these products, therefore, in order to make a choice in favor of one or the model, it is important to take into account its technical characteristics. Three types of wheels can be used for powertrains:

- pneumatic. Structures have chambers and rubber tires;

- rubber. These are solid tires made up of durable rubber and rims;

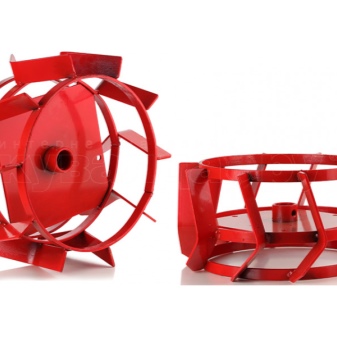

- lugs. They are metal elements that are used to increase the permeability of the walk-behind tractor.

In addition, you can find on sale and universal samples, suitable for equipment of any brands and models. They come with a camera, discs, fasteners and are considered a great choice for those who do not like to pay twice. Manufacturers often produce special wheels that are designed only for a specific modification of the walk-behind tractor. These types are sold at different prices, and they can be purchased only if the walk-behind tractor has a popular model. For units of the middle and high class, you can buy chamber wheels with a diameter of 5 to 13 inches, they have high-quality rubber and durable iron tires.

How to choose

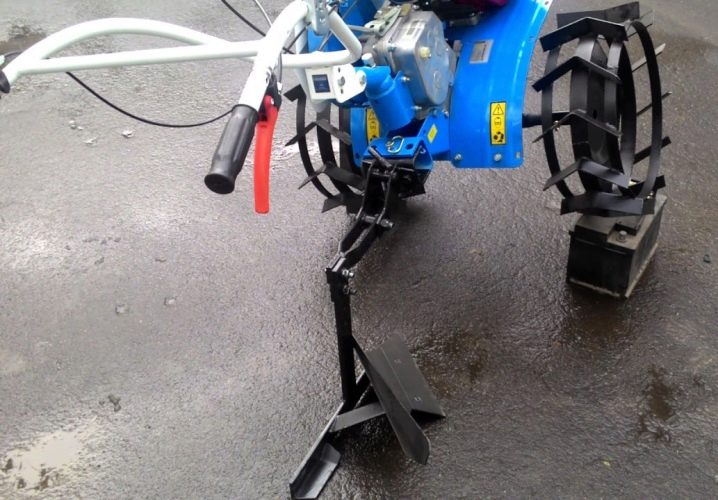

For the operation of equipment in winter, you can install twin wheels. They consist of two parts that have the same shape and dimensions. Thanks to this design, the undercarriage provides the walk-behind tractor with good cross-country ability over uneven areas. On a flat surface, the speed of the technique increases significantly. In the presence of such chassis, slipping is excluded.

When choosing wheels for a walk-behind tractor, it is also important to take into account their operating conditions. For example, for processing wet and clayey soil, not pneumatic wheels are suitable, but iron wheels with lugs. In addition, if the equipment is equipped with paired rubber wheels, it will not be able to show high performance in difficult conditions. Additionally, it is also worth paying attention to the size of the tires - it is best to choose large and wide wheels with a pattern on the tread. The best option would be if you have two types of undercarriage available, for example, pneumatic and iron with grousers.

The choice of wheels also depends on the intended use of the equipment. So, for cleaning planting work, it is recommended to purchase pneumatic ones. Their radius can be up to 40 cm, and they are adapted to work on normal ground. Experts recommend buying undercarriage with deep tread to increase cross-country ability and maneuverability. If it is planned to cultivate soil containing stones or representing virgin soil, then cast wheels will be the right solution.

An important criterion in the selection is the weight of the walk-behind tractor and its attachments. For heavy equipment, it is recommended to select cross-country chassis with strong metal rims, they can also carry loads.Do not install low pressure tires on equipment. When driving on a dirt road or asphalt for heavy equipment, chamber wheels in the size of 6.00-12 inches are well suited. They are equipped with extensions and fasteners.

The tires of the F-122 model have also proven themselves very well. They have increased cross-country ability, the tread depth is 22 mm, the pressure in the chamber is 160/400 kPa. To make the right choice in favor of a particular type of tire, you should pay attention to their labeling. It contains information about the type of tire construction, its speed index and possible load. The decoding of these designations is usually provided by product manufacturers in the form of a table.

Additionally, you can expand the capabilities of the wheels by installing extension cords. They are usually mounted on a machine when working on difficult ground. These devices also increase the maneuverability of the vehicle. Extension cords are sold in various sizes from 200mm to 375mm.

When choosing them, it is important to pay attention that the diameter of the bore hole inside coincides with the technical characteristics of the walk-behind tractor.

To summarize, we can say that each type of wheel has its own pros and cons. Therefore, when purchasing running gear for a walk-behind tractor, you need to know what kind of work will be performed by it. If we compare the technical characteristics of iron and pneumatic wheels, then the former have more advantages, since they additionally increase the power of the equipment and withstand any loads. As for the pneumatic ones, they provide the walk-behind tractor with stability, but they are quickly damaged and require replacement.

Installation

During operation, the wheels of the walk-behind tractor wear out and fail. In addition, the modernization of the chassis is also carried out in the case when it is necessary to improve the quality of plowing of the land or to increase the permeability of the unit. To properly fit the large rubber wheels on the machine, you need to pay attention to the arrow on the side of the tire. It will indicate the desired direction of rotation. First, the old wheel with a disc is removed, for this, the bolts are unscrewed and turned 180, then a new one is attached.

How to do it yourself

Despite the fact that the modern market is represented by a huge selection of running parts for walk-behind tractors, many equipment owners prefer to make wheels for them on their own. This process may seem complicated, but if you have patience and do everything in stages, you get good tires. The assembly diagram looks like this:

- First you need to find old rims from the car, of which only the rim will be used. The diameter of the wheels is selected in accordance with the power of the unit.

- Metal plates should be welded to the discs, their edges should touch the rim. The plates are placed over the entire outer radius of the structure. To increase their strength, they can be additionally fixed with bolts.

- Then the discs are thoroughly cleaned of burrs by sanding with a file.

- Rubber chambers are put on the obtained blanks, they are pumped with air and the wheels are installed on the walk-behind tractor.

To work on clayey areas, it is recommended to install lugs on the equipment, they have maximum grip on the ground due to the presence of special studs. Such wheels can be purchased ready-made and installed or made independently using the chassis from the Niva or Zhiguli.

The rework and installation process is as follows:

- First you need to attach the semi-shaft.

- Then remove the tires, as they are not needed for the iron hooks.

- Further, metal spikes are welded in several rows, which will provide adhesion to the soil.

- The structure is bolted to the rim.

See below for how to rework disks.

The comment was sent successfully.