Rake for a walk-behind tractor: tips for choosing and operating

One of the most popular attachments for walk-behind tractors is a tedder rake, which becomes an indispensable assistant for any owner of a summer cottage. You can buy them at any gardening store if you want, but DIYers know how to make such devices from old things. which are in the arsenal of any gardener.

Peculiarities

Rakes for a walk-behind tractor are used for the cultivation of the site - with their help they level the plowed land, collect freshly cut hay, and also rid the area of weeds and debris. Depending on the features of the installation, there are several types of such installations.

- Roll rake. They are used for collecting grass and leveling plowed soil. In order to connect such awnings to the walk-behind tractor, an adapter is used, and thanks to the rubberized handle, you can adjust the device for the operator's height. All this makes the use of the unit convenient and practical. Rollers are made of stainless steel - this makes them durable and reliable.

- Rake-tedders (they are also called transverse). They are needed in order to stir up freshly cut grass - this is necessary so that it dries out as quickly and evenly as possible, otherwise, smoldering begins, and the workpieces become unusable. This type of rake allows you to collect hay in the shafts. The device clings to the back of the walk-behind tractor and is characterized by a rather large size.

Popular models

When choosing the optimal model, you should take into account the functional features and the method of fastening the product. If the rake is made with high quality, then the efficiency of the work performed by them increases many times over. The most popular models are the Neva and Solnyshko rakes. Let's take a closer look at their features.

Rake for motoblocks "Neva"

Despite their name, these devices are equally well suited to all types of walk-behind tractors, as they are equipped with a special adapter that adapts to any parameters of walk-behind tractors. The working surface is approximately 50 cm, which means that such devices can be used both on large cultivated areas and in small areas.

The rake is characterized by a spring structure - due to this feature, they do not move so firmly on the ground, but slightly change their amplitude. This makes the rake more flexible, and also prevents the teeth from bending and breaking, which quite often causes malfunctions of firmly fixed rakes for walk-behind tractors.

It should be noted that the "Neva" rake successfully works with dry hay, as well as with straw and fallen leaves.

"Sun"

These are hay rakes-tedders made in Ukraine. They are used to dry the hay from all sides, and in a short time period they do the same work that manually requires 1-2 days. The quality of the harvested hay speaks better than any words about the effectiveness of such a device, so users have no doubts about the relevance of such a unit in any farm.

The unusual name is associated with the peculiar configuration of the installation - it is rounded and equipped with rather thin hooks for cut grass, which resemble rays.Such rakes can be two-, three- and even four-ring, and the greater the number of rings, the greater the width of the processed strip. So, for example, a rake with four rings can turn hay on a plot of 2.9 meters, and rake - 1.9 meters. The efficiency of the "Sun" is 1 hectare / hour. This favorably distinguishes the model from many other analogues, and given that the walk-behind tractor itself develops a speed of 8-10 km / h, the total speed of harvesting only increases.

Czech tape models and the VM-3 model are also popular among the owners of summer cottages of a large area.

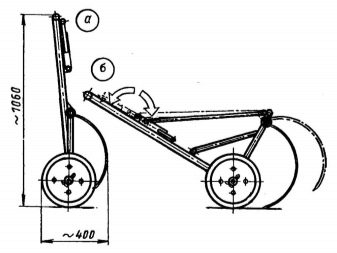

Homemade rake

It should be noted that the cost of a factory-made rake is quite high, so many craftsmen make these devices with their own hands. Naturally, the efficiency and speed of work in this case will be lower than industrial options, but if we are talking about a small farm, then the method is quite justified.

To make such a rake, you need to prepare all the basic tools and consumables:

- wheels 0.4 m in size;

- steel axle made of pipe;

- steel rods with a diameter of 0.7-0.8 cm to create a working device;

- drawbar;

- springs.

To begin with, the wheels and the axle should be made - this is a very important stage, since they become the skeleton on which the whole structure is held. Typically, wheels are borrowed from unnecessary garden equipment, such as a broken grain planter. You can also buy wheels in a store - the cheapest models cost about 1.5 thousand rubles.

The bearing should be removed from the wheel, then - find a steel strip no more than 2 cm thick, up to 4.5 mm wide and about 1.8 m long. This strip is wrapped around both discs, and then welded along the end side. As a result, the tread width will be approximately 4 cm.

Then the axle should be fastened. To do this, take a steel pipe suitable for the size of the wheel hole and carefully thread it in such a way that it protrudes slightly. On the inner surface of the wheel, special retaining rings are attached on both sides, and small holes for the cotter pin are made on the outer surface with a drill - they look like fasteners in the form of a semicircular sharp rod.

In the very center of the pipe, you need to make a mark, and then drill a hole 2.9-3.2 mm and insert a cotter pin. If you don't have it at hand, the electrode from the welding device will do - it is given a loop-shaped shape specific to the cotter pin and the braid is upholstered.

To make it easier to fix the frame, you need to attach a pair of steel squares at a distance of 10-15 cm from each wheel, while the strips should be at least 2 cm wide and 10 cm long, and the thickness of the metal should be approximately 2 mm.

A very important stage is the strengthening of the structure. For this, special horizontal support posts are made from a metal profile. You will need two squares about 1.2 m long with dimensions of 25x25 mm - they must be fixed parallel to each other. If at the end of these manipulations you notice that the length turned out to be different, you should remove the excess with a grinder.

Then it is necessary to mount the drawbar. To do this work correctly, measure the distance between the supports with a tape measure, divide it in two and get the center where the drawbar should be attached. Usually, for its manufacture, a pipe with a diameter of 30 mm or more is used, and the length of the device should be about 1.5 m. It should be noted that the net weight of the rake is approximately 15 kg. (without additional reinforcement of wheels and axles and supports), therefore, in order to reduce the risk of kinking motor vehicles and make the installation resistant to mechanical damage, a pair of square metal layers 15 * 15 mm in size are attached. They are attached in the most vulnerable areas, while the first parallel is fixed in the center between both posts, and the second functional reinforcement will be the thrust, which is responsible for the effective raising and lowering of the rake.

After the rake frame is ready, only a bar should be made, then - weld elastic springs to it and hook it all to the traction. For the manufacture of the strip, a pipe with a size of 30 mm in diameter will be needed. If it is long, then you just need to cut off the excess - no more than 1.3 meters is needed in the work - this will be the main working width of the equipment.

To fix the upper bar horizontally, a pair of 10-15 cm pipe sections with a diameter of about 40 mm are welded to the manufactured racks, then a free axis is threaded through them - as a result, a one-piece structure is obtained in which the upper pipe easily turns around its own axis

To reduce the likelihood of it slipping out and secure it in the desired position, you should install retaining rings or the most common pins on both sides. After that, you should again work with the traction: a steel corner is hooked in the center of its upper bar and welded, the traction is fixed to it from one end, and from the other - it is fixed at a distance from the middle of the drawbar. After that, it remains only to weld the springs and start testing the technique.

Regardless of whether you have a home-made rake or a store rake, you should lubricate all moving parts with grease from time to time in order to reduce friction and, accordingly, extend the life of the installation.

See below for details.

The comment was sent successfully.