Motoblocks Lifan: varieties and features of operation

Motoblocks are very popular today. Let's consider in detail the characteristics of devices of the well-known brand Lifan.

Peculiarities

The Lifan walk-behind tractor is a reliable technique, the purpose of which is tillage. The mechanical unit is considered universal. In fact, it is a mini tractor. Such means of small-scale mechanization are widespread in agriculture.

Unlike cultivators, the motors of the walk-behind tractors are more powerful, and the attachments are more diverse. The engine power is important for the volume of the territory that is intended for processing by the unit.

The 168-F2 engine is installed on the classic Lifan. Its main features:

- single-cylinder with a lower camshaft;

- rod drive for valves;

- crankcase with cylinder - one whole piece;

- air-forced engine cooling system;

- transistor ignition system.

For an hour of operation of the engine with a capacity of 5.4 liters. with. 1.1 liters of AI 95 gasoline or slightly more fuel of a lower quality will be consumed. The latter factor will not affect the operation of the engine due to the low compression ratio of the fuel. It is flame retardant. However, from a technical point of view, this could damage the engine. The compression ratio of Lifan engines is up to 10.5. This number is even suitable for AI 92.

The device is equipped with a knock sensor that reads vibrations. The pulses transmitted by the sensor are sent to the ECU. If necessary, the automatic system readjusts the quality of the fuel mixture, enriching or depleting it.

The engine will work on the AI 92 no worse, but the fuel consumption will be high. When plowing virgin lands, there will be a heavy load.

If it turns out to be long, it can have a devastating effect on the structure.

Varieties

All walk-behind tractors can be divided into three groups:

- with wheels;

- with a cutter;

- series "mini".

The first group includes devices suitable for processing large agricultural areas. The second group includes milling devices that have a milling cutter instead of wheels. These are lightweight and maneuverable units, easy to operate. The devices are suitable for cultivating small agricultural land.

In the third group of Lifan devices, a technique is presented with which it is possible to process already plowed lands from weeds by loosening. The designs are distinguished by their maneuverability, the presence of a wheel module and a cutter. The devices are lightweight, easy to operate, which even women and retirees can handle.

A built-in damper dampens vibrations and vibrations that normally occur inside the device when moving in a working position.

There are three popular series of the brand's motoblocks.

- Units 1W - equipped with diesel engines.

- Models in the G900 series are a four-stroke, single-cylinder engine equipped with a manual start system.

- Devices equipped with a 190 F engine, with a capacity of 13 hp. with. Such power units are analogs of Japanese Honda products. The cost of the latter is much higher.

Diesel models of the first series differ in power from 500 to 1300 rpm, from 6 to 10 liters. with. Wheel parameters: height - from 33 to 60 cm, width - from 13 to 15 cm. The cost of products varies from 26 to 46 thousand rubles. The type of transmission of power units is chain or variable.The advantage of the belt drive is the softness of the stroke. A worn belt is easier to replace yourself. Chain gearboxes are often equipped with a reverse, which makes it possible to reverse.

WG 900 provides for the use of additional equipment. The device is equipped with both wheels and a high-quality cutter. The equipment provides for high-quality work without power loss, even when cultivating virgin lands. There is a speed selector that regulates two-speed forward and 1 speed reverse.

The power unit 190 F is petrol / diesel. Compression ratio - 8.0, can work on any fuel. Equipped with a contactless ignition system. A liter of oil is enough for the engine with a full tank volume of 6.5 liters.

Among the popular models, one can distinguish 1WG900 with a capacity of 6.5 liters. with., as well as 1WG1100-D with a capacity of 9 liters. with. The second version has a 177F engine, PTO shaft.

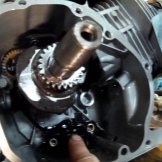

Design and principle of operation

To prevent some breakdowns, the brand's walk-behind tractors, like any other technique, require maintenance.

The unit has few main components:

- engine;

- transmission;

- wheels;

- steering system.

The motor installation kit includes an engine with transmission and power system.

It includes:

- carburetor;

- starter;

- centrifugal speed controller;

- speed shift knob.

The metal plate is designed to adjust the depth of soil cultivation. The three-groove pulley is a clutch system. The muffler is not provided in the design of the walk-behind tractor, and the air filter is installed if there is an appropriate cooling system.

Diesel engines are cooled by a water-powered structure or a special fluid.

The principle of operation of a motor cultivator is based on the action of the cutter. These are separate segments, the number of which is selected depending on the required width of the cultivated area. Another important point affecting their number is the type of soil. In heavy and clayey areas, it is recommended to reduce the number of sections.

The coulter (metal plate) is installed at the rear of the machine in a vertical position. The possible tillage depth is related to the size of the cutters. These parts are protected with a special shield. When open and in working order, they are highly hazardous parts. Parts of the human body can get under the rotating cutters, clothes are tightened in them. For safety reasons, some models are equipped with an emergency lever. It should not be confused with the throttle and clutch levers.

The cultivator's capabilities are expanded with the help of additional attachments.

Operating rules

Maintenance of the walk-behind tractor is impossible without such actions as:

- adjustment of valves;

- checking the oil in the engine and gearbox;

- cleaning and adjusting spark plugs;

- cleaning the sump and fuel tank.

To adjust the ignition and set the oil level, you do not need to be a "guru" in the car industry. The rules for operating motoblocks are detailed in the instructions that are attached to the purchased unit. Initially, all components are checked and configured:

- handlebars for the operator's height;

- parts - for the reliability of fixation;

- coolant - for sufficiency.

If the engine is gasoline, it is easier to start the walk-behind tractor. It is enough to open the petrol valve, turn the suction lever to "Start", pump the carburetor with a manual starter and turn on the ignition. The suction arm is put into the "Operation" mode.

Diesels from Lifan are started by pumping fuel, which should spill over all parts of the power unit. To do this, you need to unscrew not only the supply valve, but also every connection coming from it, up to the nozzle. After that, the gas is adjusted to the middle position and pressed several times. Then it must be pulled and not released until it reaches the starting point.Then it remains to press the decompressor and starter.

After that, the unit with a diesel engine should start.

Care features

Monitoring the walk-behind tractor assumes compliance with the operating rules.

Basic moments:

- timely elimination of the appeared leakage;

- tracking the functionality of the gearbox;

- periodic adjustment of the ignition system;

- replacement of piston rings.

Maintenance times are set by the manufacturer. For example, Lifan recommends cleaning the walk-behind tractor assemblies after each use. The air filter should be checked every 5 hours of operation. Its replacement will be required after 50 hours of movement of the unit.

Spark plugs should be checked every working day of the unit and replaced once a season. It is recommended to pour oil into the crankcase every 25 hours of continuous operation. The same lubricant in the gearbox is changed once a season. With the same frequency, it is worth lubricating the fixing parts and assemblies. Before starting seasonal work, they are inspected, and if necessary, all cables and a belt are adjusted.

After long-term operation of the device, it is not recommended to touch the parts, even if there is a need for inspection or topping up oil. Better to wait a while. During operation, parts and assemblies heat up, so they must cool down. If the maintenance of the walk-behind tractor is performed correctly and constantly, this will help to extend the life of the unit for many years.

A quick failure of various units and parts leads to breakdown and the need to repair the device.

Possible problems and how to deal with them

Most of the problems in motoblocks are identical for all engines and assemblies. If the unit has lost the power of the power unit, the reason may be storage in a damp place. This can be corrected by idling the power unit. You need to turn it on and leave it to work for a while. If power is not restored, disassembly and cleaning remains. In the absence of skills for this service, it is better to contact the service.

Also, engine power may drop due to a clogged carburetor, gas hose, air filter, carbon deposits on the cylinder.

The engine will not start due to:

- wrong position (it is advisable to hold the device horizontally);

- lack of fuel in the carburetor (cleaning of the fuel system with air is required);

- a clogged gas tank outlet (elimination is also reduced to cleaning);

- a disconnected spark plug (the malfunction is excluded by replacing the part).

When the engine is running, but intermittently, it is possible:

- it needs to be warmed up;

- the candle is dirty (it can be cleaned);

- the wire does not fit tightly to the candle (you need to unscrew and carefully screw it into place).

When the engine shows unstable rpm during idle warm-up, the cause may be an increased clearance of the gear cover. The ideal size is 0.2 cm.

If the walk-behind tractor starts to smoke, it is possible that low-quality gasoline is poured or the unit is tilted too much. Until the oil that gets on the gearbox burns out, the smoke will not stop.

If the starter of the device screeches strongly, most likely the power system is not able to cope with the load. This breakdown is also observed when there is insufficient fuel or a clogged valve. It is necessary to eliminate the identified deficiencies in a timely manner.

The main problems with walk-behind tractors are associated with a failure of the ignition system. For example, when a characteristic carbon deposit forms on the candles, it is enough to clean it off with sandpaper. The part should be washed in gasoline and dried. If the gap between the electrodes does not correspond to the standard indicators, it is enough to bend or straighten them. The deformation of the wire insulators is only changed by the installation of new connections.

There are also violations in the angles of the candles. Deformation of the starter of the ignition system occurs. These problems are eliminated by replacing parts.

If belts and adjusters loosen with heavy use, they will self-adjust.

How to adjust the valves of the Lifan 168F-2,170F, 177F engine, see the video below.

The comment was sent successfully.