How to choose a harrow for a walk-behind tractor?

The harrow for a walk-behind tractor is a popular type of attachment and is used for various agricultural operations. The high demand for the device is due to its ease of use, versatility and wide consumer availability.

Features of harrowing

Harrowing is considered the most important stage of soil cultivation, on which the state of crops and the yield of crops grown depend. This agrotechnical measure solves several problems at once, the main of which are the destruction of weeds and loosening of the soil. Besides, harrowing effectively levels the ground and significantly reduces moisture loss... The loosening effect is achieved due to the action on the soil of working elements fixed on a common frame and in the form of discs, tines or hoes.

Such a device is called a harrow and has been known to mankind for a long time. It used to be the lot of working horses to carry a harrow, but today, thanks to the mechanization of the process, this role is assigned to agricultural machinery.

In large farms, mini-tractors are more often used as a tractor for the harrow, while summer residents and owners of small plots increasingly prefer motoblocks.

The harrowing process is carried out twice a year.... The first time - in early spring, immediately after the soil thawed, and the second - after the last harvest, shortly before the first frost.

Views

The harrow for a walk-behind tractor is of several types: tooth, needle, disc and rotary (rotary).

Dental model

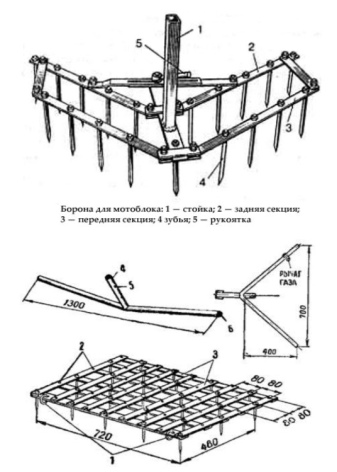

It is the simplest type of equipment and is a miniature copy of the classic harrow that tractors are equipped with. Structurally, it is made in the form of a wedge-shaped or rectangular frame, with metal teeth from 25 to 40 mm in length placed on it. The arrangement of the teeth on the frame varies, however, the most common option is zigzag, while the teeth themselves can have both round and rectangular cross-sections.

The tine harrow is able to loosen the soil by 10-14 cm, which contributes to the normalization of air exchange and regulates the water balance.

To connect the harrow to the walk-behind tractor, a chain or rigid coupling is used, and to obtain a higher harrowing effect, hard teeth are sometimes replaced with spring ones.

The advantage of the view is the simplicity of the design, the absence of complex assemblies and the ability to make the device with your own hands.

The main working characteristics of the tooth model can be considered on the example of the widespread two-track harrow BN-1, which is designed specifically for the Neva walk-behind tractor. Using this model, loosening is performed, large clods of soil formed as a result of plowing are crushed and leveling of the topsoil is performed.

The depth of soil processing varies from 3 to 10 cm, and the productivity is 0.2-0.5 hectares / hour... The grip width is regulated with a special handle and ranges from 60 to 100 cm. The dimensions of the model are 72x67x51 cm, weight - 17 kg, and the optimum harrowing speed is 4 km / h.

Fastening to the walk-behind tractor is carried out by means of a screw mechanism using a universal hitch.

Needle model

By its design, it is somewhat reminiscent of a tooth, however, differs from it in that instead of the teeth welded to the frame, replaceable arcuate perforated pins are installed... This harrow allows you to cultivate stubble and is used to level the soil, which prevents it from drying out.

The devices are designed for powerful water-cooled motoblocks weighing from 200 kg.

As an example of a needle model, you can consider the harrow for the Zubr walk-behind tractor. The grip width of this device is 1 m, and the loosening depth reaches 14 cm.

The device is attached to the walk-behind tractor by means of a rigid hitch with an adjustment mechanism. The harrow weighs 30 kg.

Disk model

It is presented in the form of spherical discs, which have a smooth or perforated design. Using a harrow with perforated discs gives the best processing results, however, it requires constant cleaning of the working surface during harrowing..

The discs are attached to the frame at a different angle of inclination, which in each case is set by the operator of the walk-behind tractor and depends on the type of soil and its condition. The principle of operation of disc models is quite simple and consists in the following: while the walk-behind tractor is moving, the harrow discs cut off the top layer of the earth and grind it. In this case, the weeds are turned inside out and cut.

Attaching the disc harrow to the walk-behind tractor can be done in front and behind the unit. and depends on the model of the walk-behind tractor and the type of attachments.

The range of disk devices is wide enough, so it would be unfair to take any one model as a reference. In the line of disk devices, there are mainly quite powerful devices.... The largest of them have a working width of up to 140 cm, they can go 20 cm into the ground and weigh up to 70 kg.

Such devices are installed on motoblocks of medium and heavy class and are attached to them by means of a rigid adjustable hitch.

Rotary or rotary models

They belong to the active class of attachments. Their difference from the three previous passive models is that they are not attached to the walk-behind tractor by means of a hitch, but are installed on the unit instead of wheels. The working part of such devices is presented in the form of pointed plates located on disks, which are installed at a certain angle. It is the plates that are the working mechanism and carry out the soil cultivation.

The depth of entry into the ground for rotary models is quite small and is only 7 cm, which is quite enough for cultivating the land immediately after harvesting grain crops. The greatest efficiency can be achieved when installing rotary models on walk-behind tractors with gearboxes.

The scope of application of rotary devices is somewhat wider than that of other species and, along with loosening and leveling the earth, includes the possibility of sowing seeds and effectively covering them. This method leads to a significant reduction in seed loss and significantly increases yields.

In addition to the introduction of seeds, using a rotary harrow, mineral fertilizers are injected to the desired depth.

As an example, we can consider a Russian-made rotary harrow for the Neva walk-behind tractor. The device is capable of effectively leveling the soil after plowing and adding mineral additives to a depth of 5 to 7 cm.

Greater processing efficiency can be achieved when the walk-behind tractor is moving at a speed of 4 km / h.

The harrowing width of such a device is 1.4 m with a length of one section of 70 cm and a harrow diameter of 35 cm. The depth of loosening is somewhat greater than that of other models of this type and reaches 10 cm. The weight of one section is 9 kg.

Criterias of choice

Before proceeding with the purchase of a harrow for a walk-behind tractor, you should decide on the type of soil on which the equipment will be used, as well as the type of processing. So, for the development of soft virgin lands, it is better to purchase a rotary model.Despite the small depth of penetration into the soil, it is with the help of this equipment that it is possible to prepare the soil for planting crops as much as possible. Besides, a rotary harrow is ideal when preparing the field for winter after harvesting potatoes.

If there is a large amount of weed on the site, which must be dealt with quickly and efficiently, then the best option would be to purchase a disc model.

The discs do well even with fairly thick roots and leave them no chance.

If you need to deeply harrow the soil, while protecting it from excessive drying out, then it is better to choose a needle model... Such products are able to penetrate deeply into the ground and leave behind a fairly flat surface.

If the site is cultivated every year and contains soft and well-groomed soil, then there is no point in overpaying for more functional equipment, so the purchase of a classic dental model will be quite enough.

See below for more details.

The comment was sent successfully.